Altitude coil online packing automatic bagging machine

A bagging machine and coiling technology, which is applied in packaging, transportation packaging, transportation and packaging, etc., can solve the problems of high labor intensity, long working hours, and low production efficiency, and achieve high-temperature radiation avoidance, significant economic benefits, The effect of low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

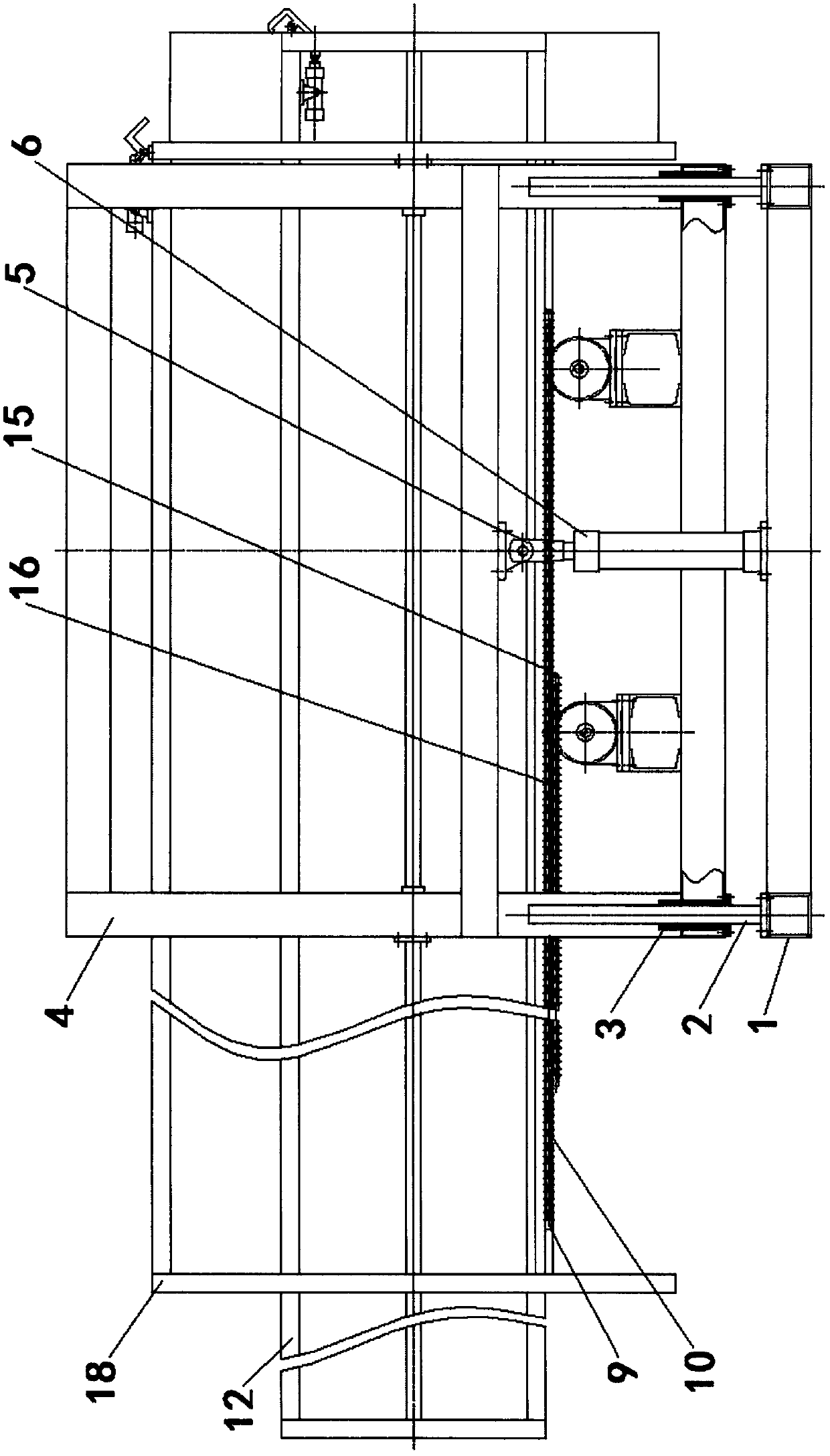

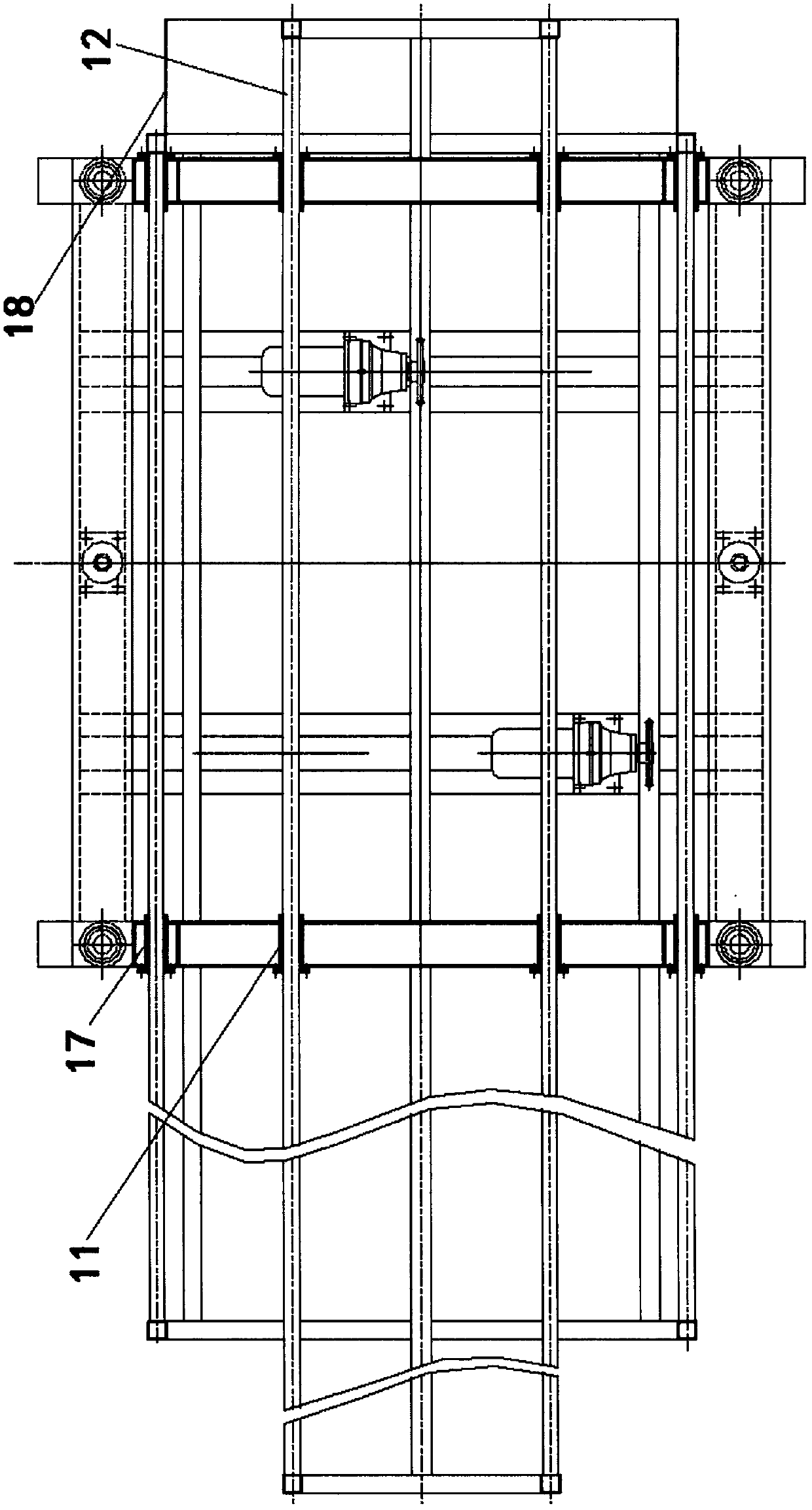

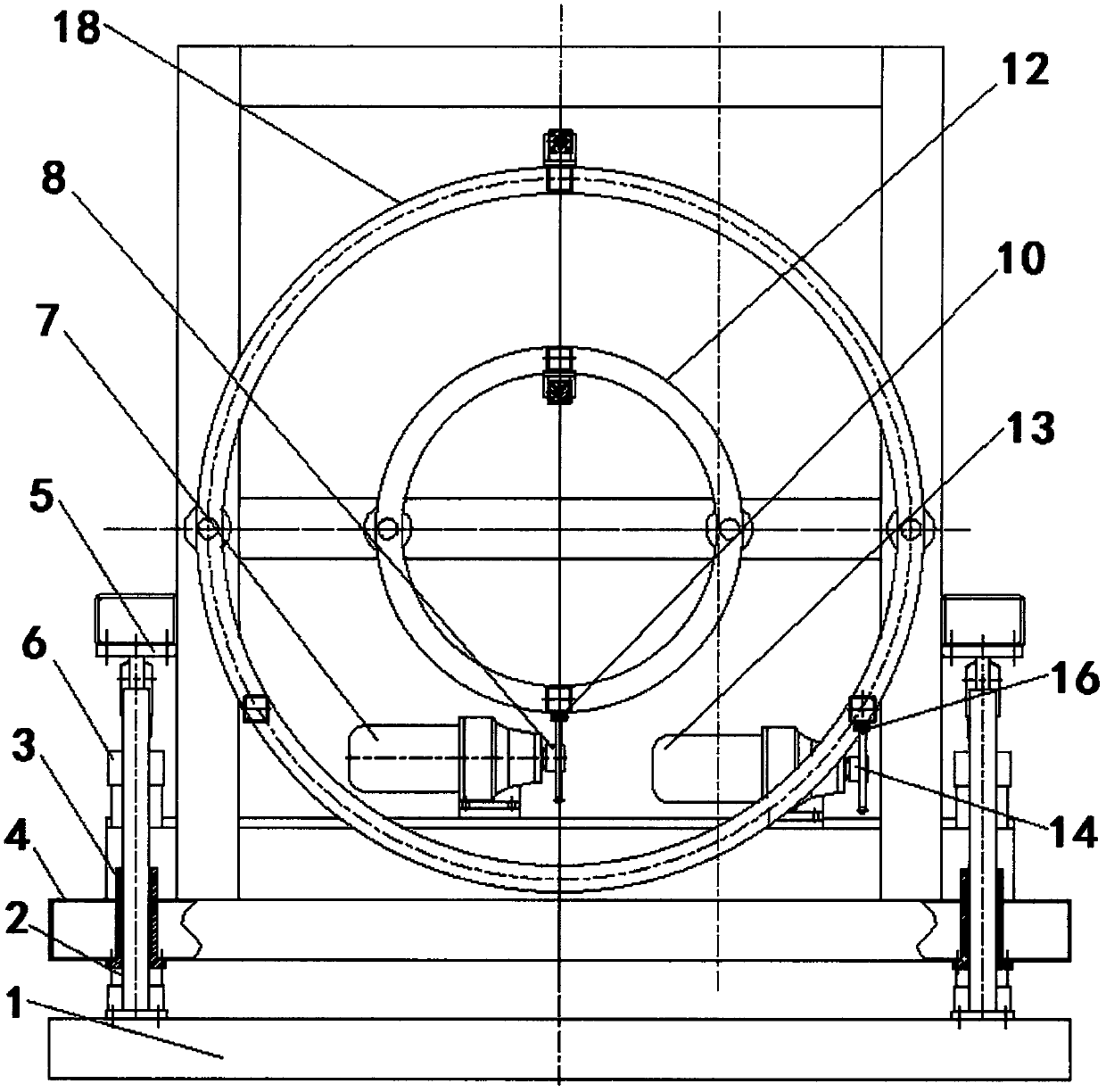

[0067] exist Figure 1 to Figure 12 Among them, the high wire coil online packaging automatic bagging machine of the present invention includes a base 1, a lifting guide column 2 installed on the base, a lifting guide sleeve 3 that cooperates with the lifting guide column and moves up and down along it, and is installed on the lifting guide column. The frame 4 that is put on, the lifting connection support 5 installed on the frame, the lifting drive device 6 that is vertically installed on the base, the end of the driving rod part is hinged with the lifting connection support, and the inner cylinder installed on the frame The driving power machine 7, the inner cylinder transmission sprocket 8 installed on the inner cylinder driving power machine, meshes with the inner cylinder transmission sprocket and transmits the inner cylinder transmission chain 10 installed along the inner cylinder longitudinally through the inner cylinder chain fixing block 9, and is installed on The inn...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap