Novel bridge maintenance device

A technology for maintaining devices and bridges, applied in bridge maintenance, bridges, bridge reinforcement, etc., can solve problems such as low efficiency, high labor intensity, and reduced maintenance efficiency, and achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

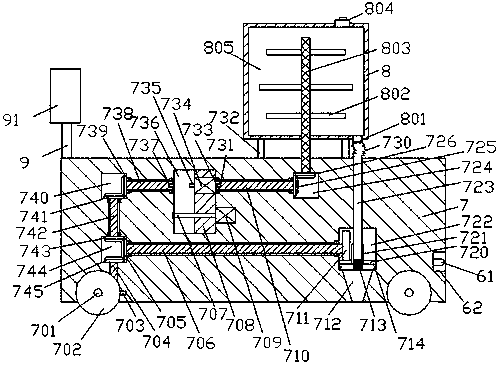

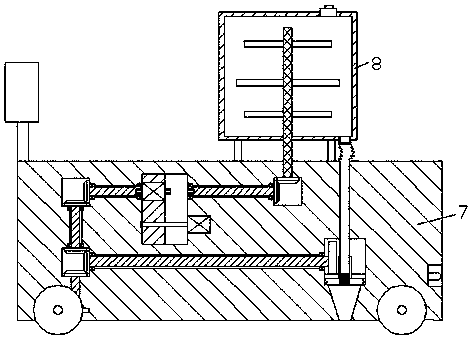

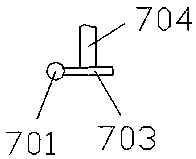

[0016] Such as Figure 1-4 As shown, a new type of bridge maintenance device of the present invention includes a vehicle frame 7 and a container 8 fixedly installed on the upper side of the vehicle frame 7, and the inner walls of the vehicle frame 7 are respectively provided with first transfer grooves 740, the second transfer groove 744, the third transfer groove 724, the sliding connection groove 736 and the fourth transfer groove 722, the sliding connection block 708 is installed in the sliding connection groove 736, and the sliding connection block 708 A screw-shaped rod 707 is installed in the middle, the left side extension end of the screw-like rod 707 is connected with the left side end wall of the sliding joint groove 736 in rotation, and the right side extension end of the screw-like rod 707 is connected with the first An electric rotating machine 709 is connected by power cooperation, the outer surface of the first electric rotating machine 709 is fixedly installed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com