Open-pit mine mining and discharging method contributing to reclaiming of inner dumping site

An open-pit mine and internal soil drainage technology, which is applied in the fields of site preparation, earth drilling, botanical equipment and methods, etc., can solve the problems of increased cost of mining and drainage reclamation operations, loss of topsoil storage, and unsatisfactory loosening effect, etc. , to achieve the effects of reducing mining and drainage costs, increasing water content, and reducing reclamation costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further explained below in conjunction with the accompanying drawings.

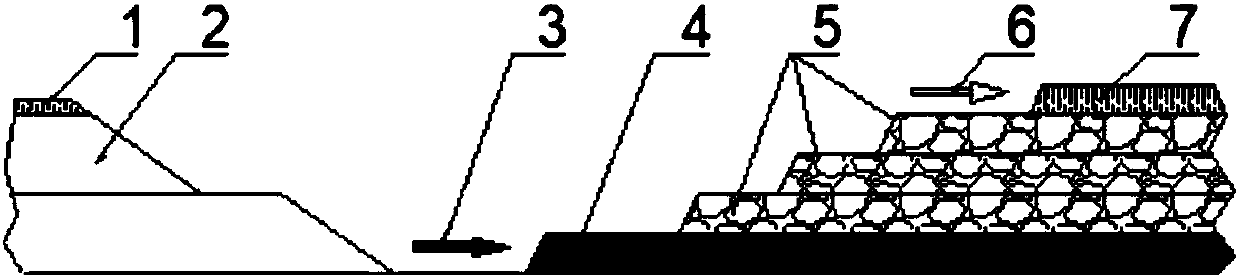

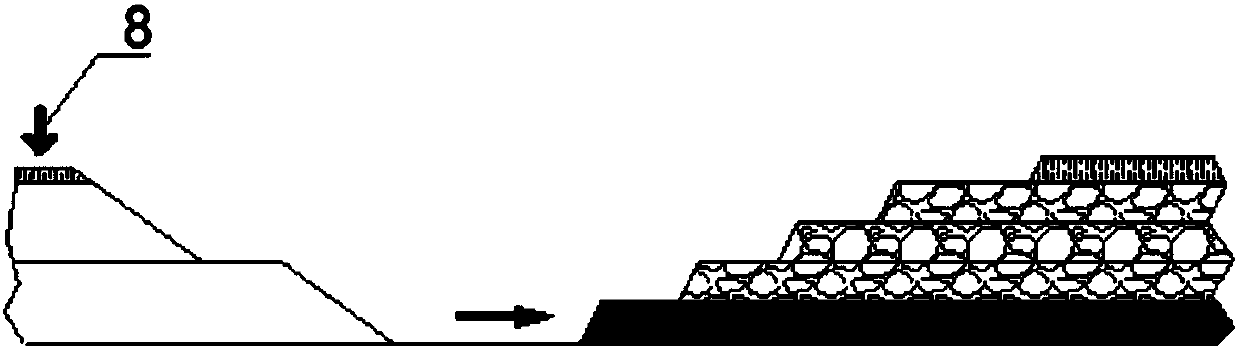

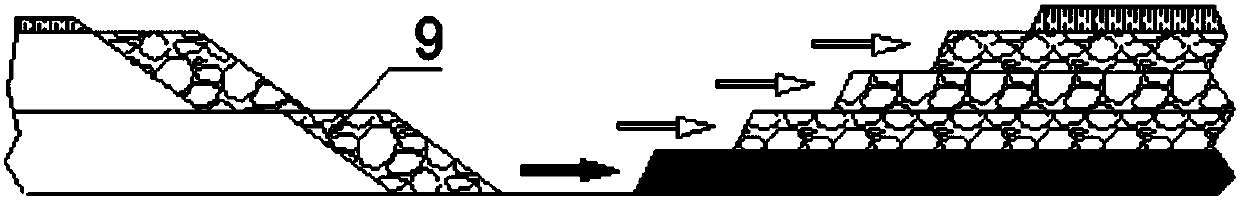

[0022] Figure 1 to Figure 4 Represented is the schematic diagram in a cycle of the mining mode that the present invention designs, and concrete process is as follows:

[0023] 1. At the beginning of the autumn of the first year, place all the stripping equipment on the surface of the open-pit mine, use mining equipment such as electric shovels, front loaders, and hydraulic excavators, and use single-bucket truck-intermittent technology or single-bucket-truck-conveyor semi The continuous process strips the surface humus 7 one year in advance and advances the distance. The stripped surface humus 7 is not piled up separately, but is directly discharged to the surface of the internal dump 2 as the soil layer 1 to be reclaimed, waiting for reclamation.

[0024] 2. In the winter of the first year, stop all surface humus 7 stripping work, and only carry out coal mining oper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com