A high-efficiency drying machine

A trigger and high-efficiency technology, applied in the field of exposure equipment for contact printing, can solve the problems of low drying efficiency and poor uniformity of the photosensitive plate, and achieve the effect of avoiding the emission of harmful gases, improving processing efficiency and ensuring health.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

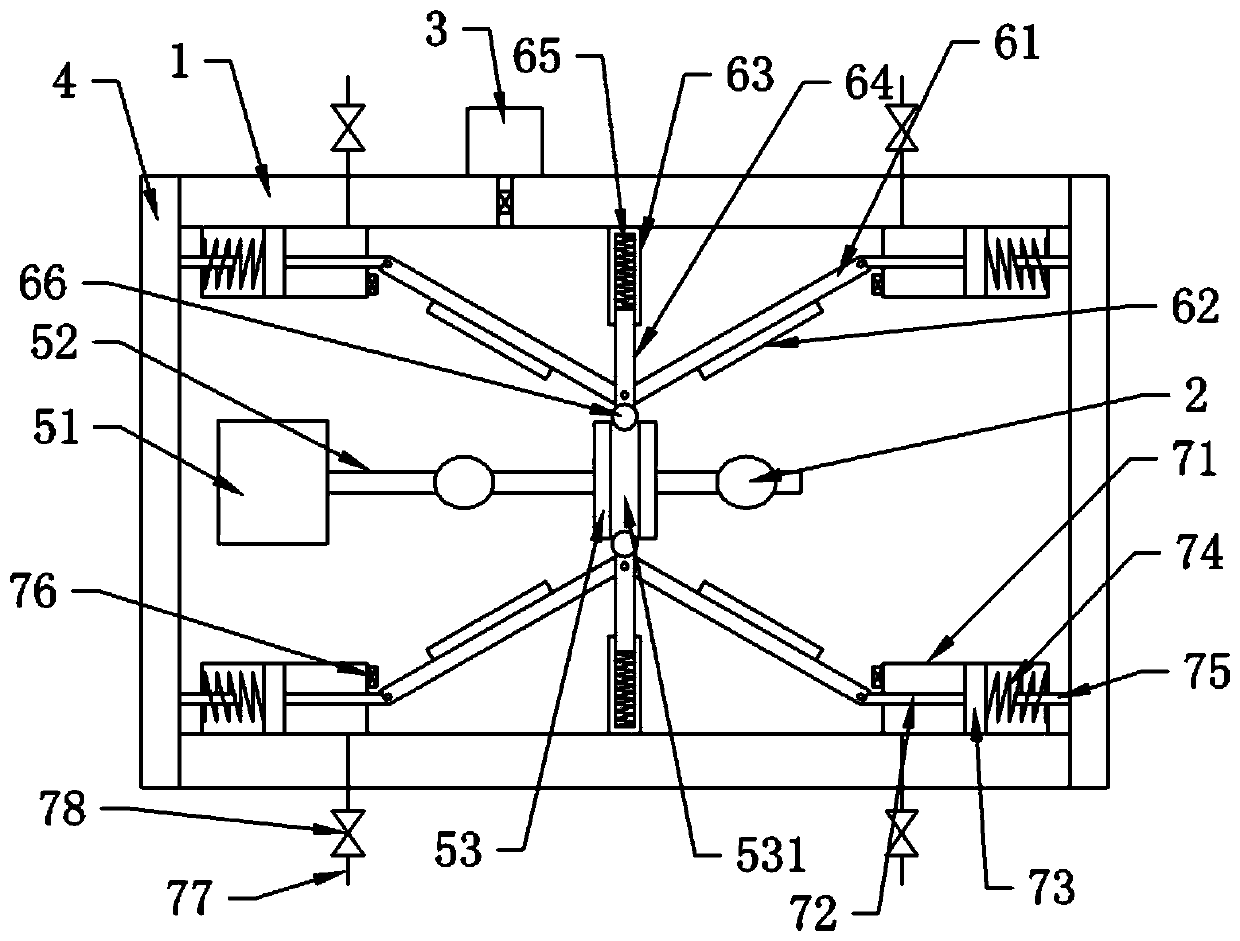

Image

Examples

Embodiment 2

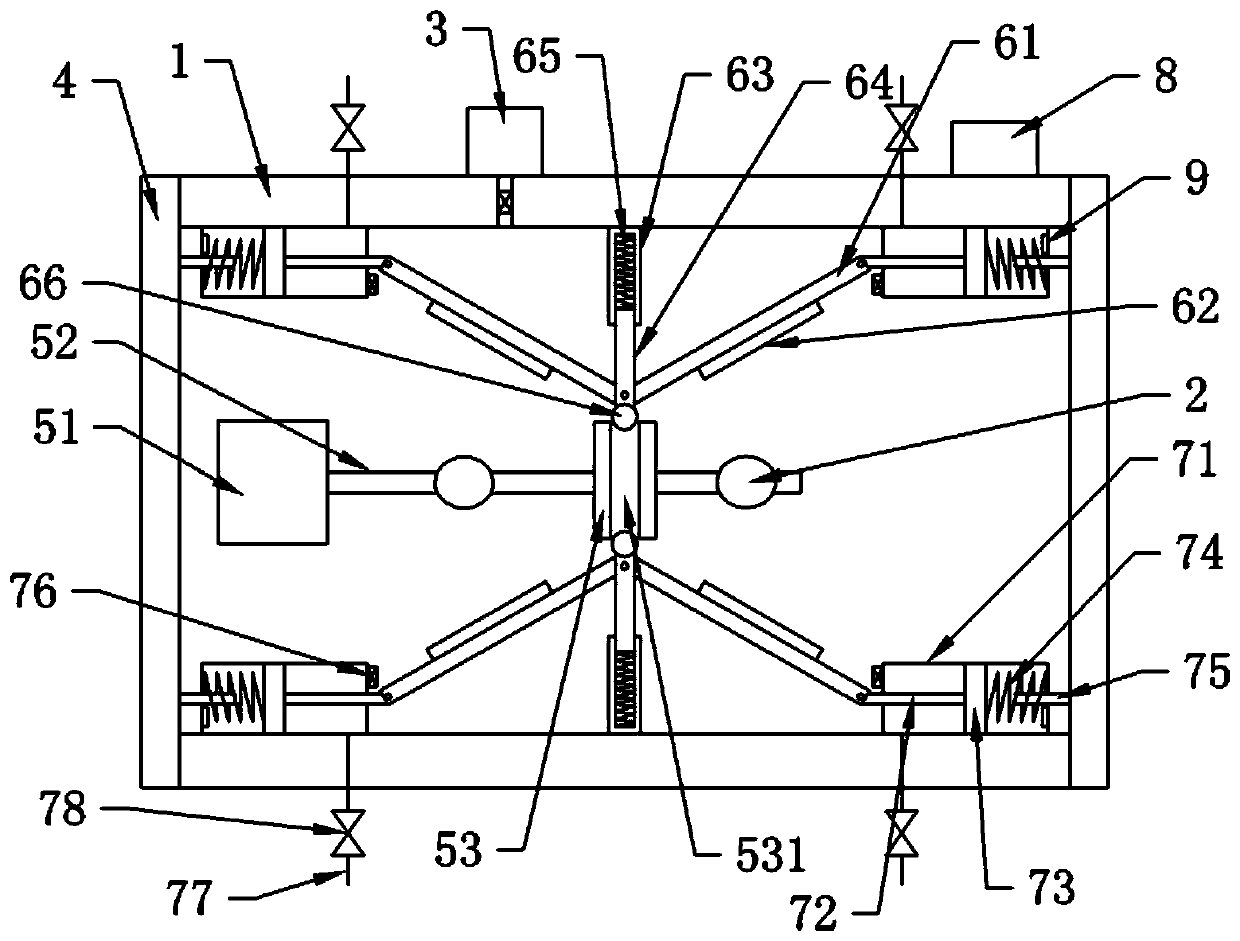

[0033] Such as figure 2 As shown, the difference between this embodiment and embodiment 1 is that the control unit also includes a controller 8 and a pressure sensor 9. The controller 8 can be a MAM-200 controller purchased on the market, and the pressure sensor 9 can be purchased on the market. PT124G-213 pressure sensor, the pressure sensor 9 is arranged at the bottom of the gas cylinder 71 away from the push rod 72, the valve 78 is an electric control valve, and the electric control valve and the pressure sensor 9 are electrically connected to the controller 8 respectively.

[0034] In this solution, as the rotating wheel 53 rotates, gas is continuously sucked in the air reservoir 71 until the piston body 73 abuts against the pressure sensor 9 and squeezes, when the pressure received by the pressure sensor 9 reaches the upper limit set by the controller 8. After the value, the controller 8 controls the electric control valve to open, thereby expelling the gas in the gas cylin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com