Duralumin pole piece and battery module

A technology for battery modules and battery packs, applied in battery pack components, multi-mode batteries, secondary battery manufacturing, etc., can solve the problems of poor welding reliability, complex welding process, low production efficiency, etc., and achieve reliable welding and lightening. Module weight and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to solve the problems of complicated welding process of electrode sheet and battery pack, poor welding reliability, high cost and production efficiency when producing battery modules, the present invention provides a hard aluminum pole piece and battery module. The present invention will be further explained below in conjunction with the drawings.

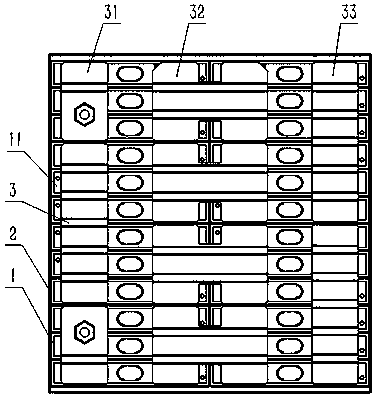

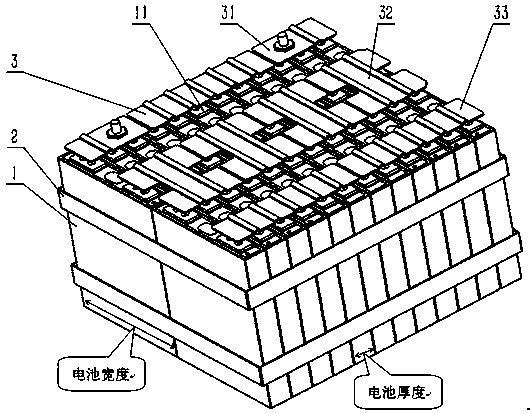

[0029] Such as figure 1 with figure 2 As shown, a hard aluminum pole piece is used in a battery module. The battery module includes a NxM matrix battery pack (1) formed by stacking a plurality of square batteries. Each battery is provided with opposite polarities. The duralumin pole piece (3) includes a total output pole piece (31), a double row duralumin pole piece (32) and a single row duralumin pole piece (33).

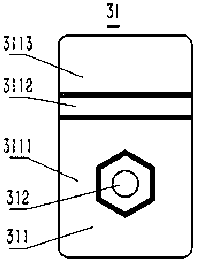

[0030] Such as figure 2 , image 3 with Figure 4 As shown, the total output pole piece (31) includes a rectangular duralumin pole piece (311) and a hexagon head screw (312) that are combined by a pressure ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com