Method for machining ZC-shaped worm-gear pair

A processing method and technology of worm gear pair, applied in the direction of gear transmission, belt/chain/gear, mechanical equipment, etc., can solve the problems of difficult processing of three-head and four-head worms, no price competitiveness, difficulty in improving efficiency, etc. Achieve the effect of improving life and transmission efficiency, improving neutrality, and reducing bending deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A kind of processing method of ZC type worm-worm gear pair, the processing of worm specifically comprises the following steps:

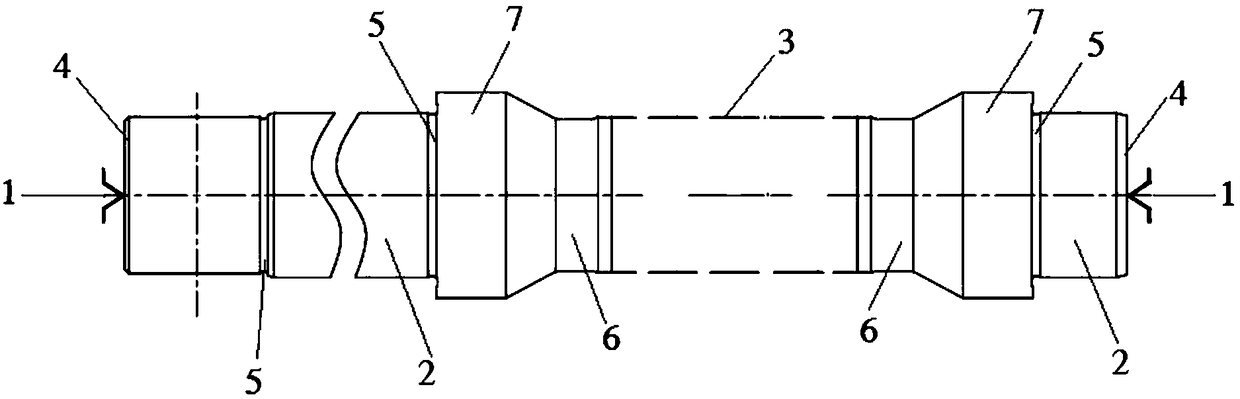

[0027] (a) Process the center hole 1 on both ends of the worm, and use the center hole 1 as the positioning reference to process the bearing installation position 2 of the worm;

[0028] (b) With the bearing installation position 2 as the positioning reference, each shaft section of the worm is processed, including the end face 4, the undercut groove 6 and the overrun groove 5, and the worm tooth 3 is milled by a whirlwind milling machine, and the worm tooth surface is roughly ground, preliminarily The remaining coarse grinding allowance is 0.2 mm, and then the worm gear 3 is heat-treated, and carburized and quenched. After carburizing and quenching, the thickness of the carburized layer is 0.8 mm, and the hardness is 58HRC;

[0029] (c) Using the bearing installation position 2 as the positioning reference, finely grind the center hole 1 on b...

Embodiment 2

[0034] The difference between this embodiment and embodiment 1 is that the coarse grinding allowance reserved in step (b) is 0.3mm, the thickness of the carburized layer after carburizing and quenching is 1.5mm, and the hardness is 62HRC. The worm-worm gear pair processed in this embodiment is tested by a type test, and its transmission efficiency is above 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com