Tensioning mechanism of tying belt and using method thereof

A technology of locking springs and sliders, which is applied to the parts of strapping machinery, etc., can solve the problems of not tight enough strapping and low work efficiency, and achieve the effects of easy control and placement, high work efficiency, and improved friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below in conjunction with drawings and embodiments.

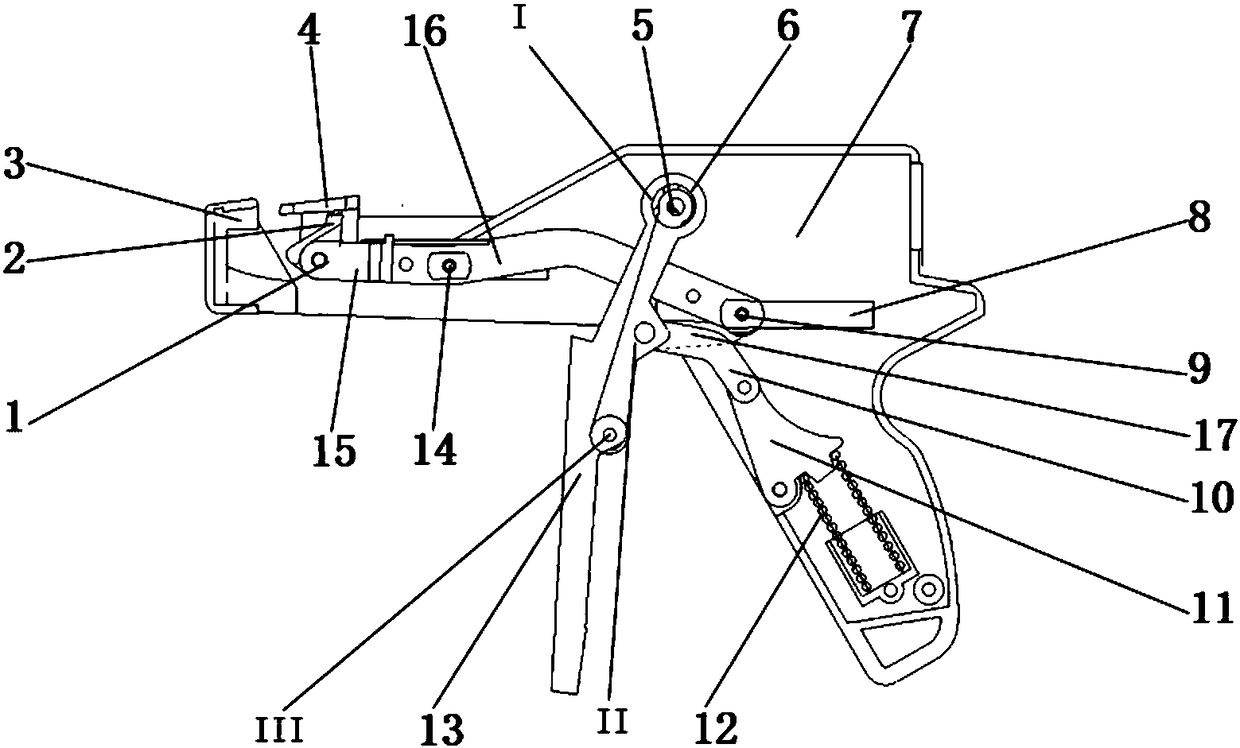

[0021] like figure 1 As shown, a tightening mechanism of a cable tie includes a locking spring 1, teeth 2, a knife case 3, a block 4, a rolling shaft 5, a first connecting piece 6, a housing 7, a chute 8, a first Slider 9, second connecting piece 10, third connecting piece 11, long spring 12, handle 13, second sliding block 14, slide bar 15, connecting rod 16, fourth connecting piece 17.

[0022] Insert the extra end of the cable tie through the elongated through groove 3-1 provided on the knife case 3, and install it between the lower surface of the baffle 4 and the upper surface of the teeth 2, wherein the baffle 4 is U-shaped, and The opening is arranged on the inner surface of the housing 7, and one end of the teeth 2 with serrations is in contact with an inner surface of the opening of the blocking piece 4U; One end of the connecting rod 15 is provided with a str...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com