Treatment process method for improving surface strength and wear resistance of rotary blade

A surface strength and treatment process technology, applied in heat treatment furnaces, heat treatment equipment, metal material coating processes, etc., can solve the problem of reducing equipment reliability and work efficiency, increasing equipment use and maintenance costs, affecting work quality and work efficiency, etc. Problems, to achieve good anti-adhesive wear ability, conducive to lubrication, good toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

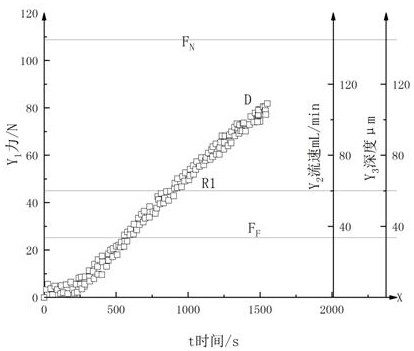

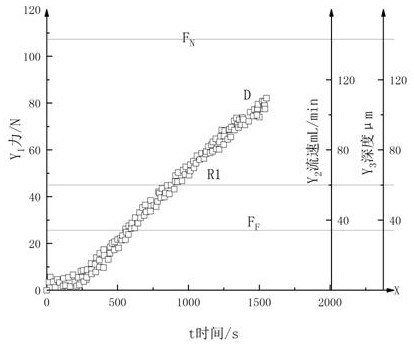

Image

Examples

Embodiment 1

[0027](1) Clean and dry the rotary tiller, clean and dry the rotary tiller, move the grinder to the surface of the rotary tiller at an angle of 5°, and move the grinder to the right, 1 / 4 of the upper left of the impeller of the grinder Align the surface of the rotary tiller, and face the front of the rotating grinding wheel to the surface. The area between the grinding marks is 50% of the rotary tiller, and the rotation speed is 4000rpm. Use No. 50 sandpaper to smooth the burrs, convex points and deep scratches. Then wash it 4 times with deionized water and dry it; (2) Put the cleaned and dried rotary tiller in a salt bath with a salt bath temperature of 750°C and a holding time of 6 hours. The mass ratio is as follows: urea: sodium carbonate, potassium chloride: diboron trioxide = 9:5:3:2; (1) urea is dried at 120°C, and boric acid is prepared from boric acid at 350- Melt at 400°C until gelatinous, and break into small pieces after cooling. Mix potassium chloride and sodium c...

Embodiment 2

[0030] (1) Clean and dry the rotary tiller, move the grinder to the surface of the rotary tiller at an angle of 10°, move the grinder to the right, align the upper left 1 / 4 of the impeller of the grinder with the surface of the rotary tiller, and rotate The front of the grinding wheel facing the surface, the coverage area between the grinding marks is 60% of the rotary tiller, the rotation speed is 4500rpm, and the burrs, convex points and deep scratches are smoothed with No. 50 sandpaper, and then cleaned 4 times with deionized water. (2) Place the cleaned and dried rotary tiller in a salt bath with a salt bath temperature of 750°C and a holding time of 6 hours. The mass ratio of the three-component co-infiltration salt bath is as follows: urea: sodium carbonate, Potassium chloride: boron trioxide = 9:5:3:2; (1) urea is dried at 120°C, and the preparation of boron trioxide is to melt boric acid at 350-400°C until gelatinous, After cooling, it is broken into small pieces. Mix ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average wear | aaaaa | aaaaa |

| Average wear | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com