Top-down construction method for intermediately-weathered geology

A construction method and reverse method technology, applied in excavation, artificial islands, water conservancy projects, etc., can solve the problems of unsuitable construction in moderately weathered geology, few, and reduced bearing capacity of column piles, so as to reduce material input and installation and dismantling costs , saving the construction period, and the effect of reasonable force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

[0066] The specific embodiment: the specific embodiment of the present invention is described in detail below in conjunction with accompanying drawing:

Embodiment

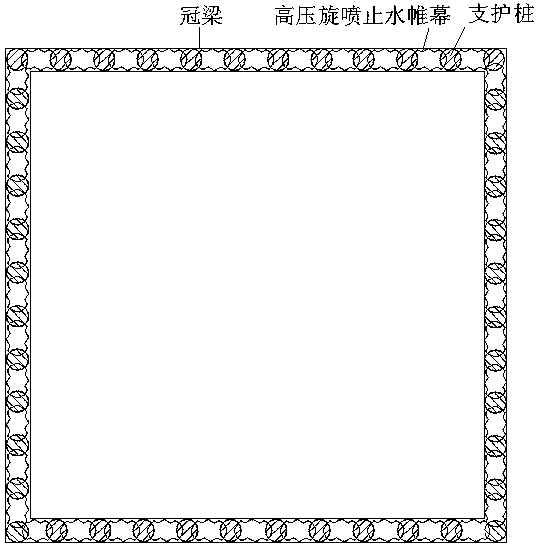

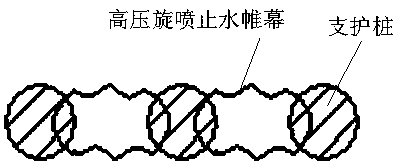

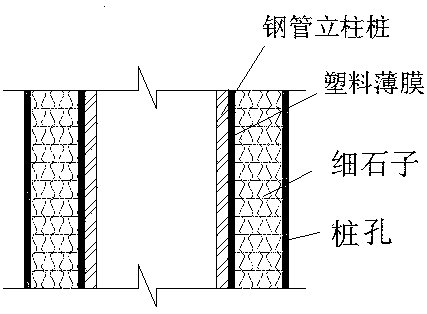

[0067] Embodiment: A construction method of moderately weathered geological reverse method, using support piles and high-pressure rotary grouting piles as the foundation pit enclosure structure, steel pipe concrete column piles as the load-bearing structure, and using the basement beam-slab system as the foundation pit internal support system , Carry out earthwork excavation and structural construction layer by layer from top to bottom, so as to achieve the purpose of layered excavation and layered support.

[0068] Construction of support piles and high-pressure jet-spraying water-stop curtains around the basement of the building, and at the same time, install concrete-filled steel pipe column piles at the corresponding design positions inside the building to bear the self-weight and construction load of the upper structure during the construction period (before the basement raft is poured) support. According to the actual situation of the project, if construction dewatering ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com