Elevator cable horizontal accelerated bending service life test equipment and test method

A bending life, elevator cable technology, applied in the direction of measuring electricity, measuring electrical variables, testing dielectric strength, etc., can solve the problems of long elevator cable life detection time cycle, shorten the development time of new elevator cable products, and high cost, and achieve development It is convenient for technical improvement, avoiding cable defects, and the effect of no cumulative error

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with accompanying drawing.

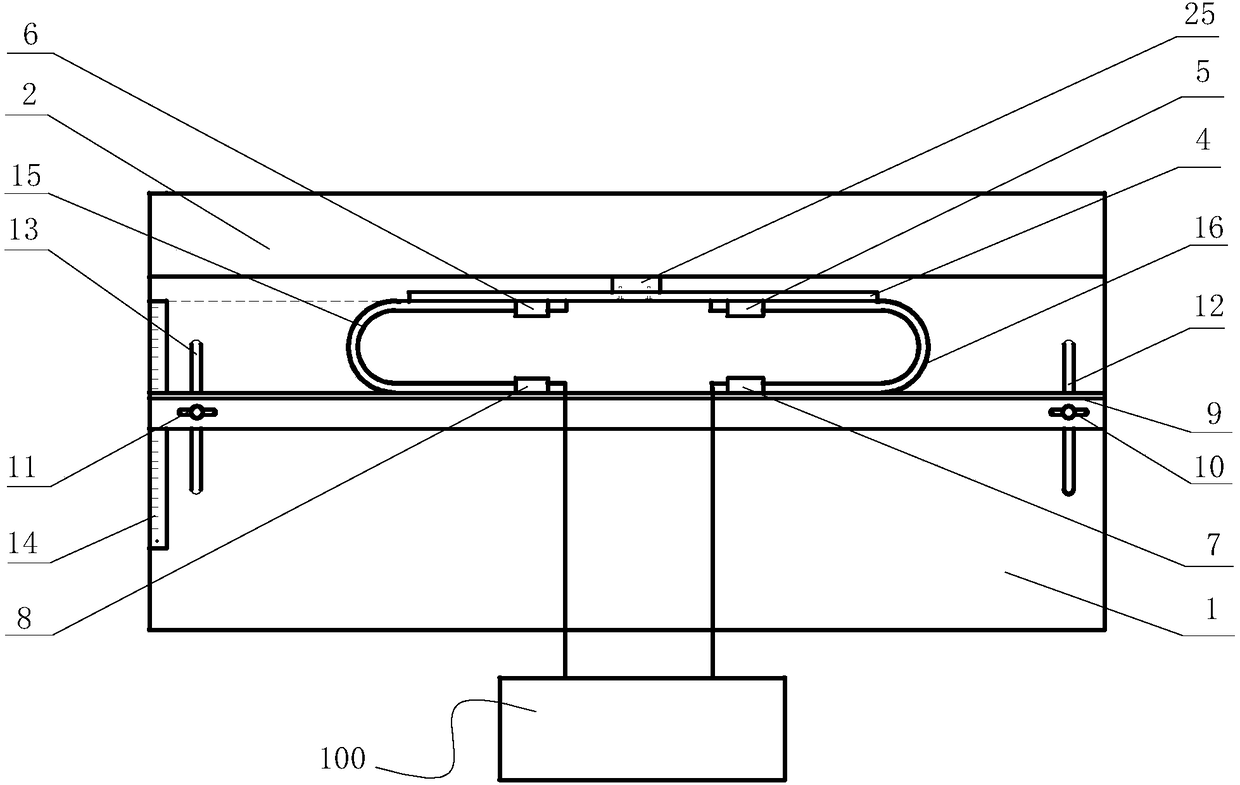

[0035] see Figure 1 to Figure 4 , the elevator cable horizontal accelerated bending life test equipment of the present invention comprises a base 1, a horizontal high-speed reciprocating mechanism and a fixed fixture mechanism arranged on the base 1, and a conduction and withstand voltage testing device 100 arranged on the periphery of the base 1.

[0036] The base 1 is the skeleton of the entire test device, which plays the role of installing other parts. Its shape is a cuboid, the upper part is a platform, and the lower part of the platform is a frame type. The four sides can be closed with stainless steel plates or other steel plates or plates of other materials. closed. The base 1 can mainly serve to install other components.

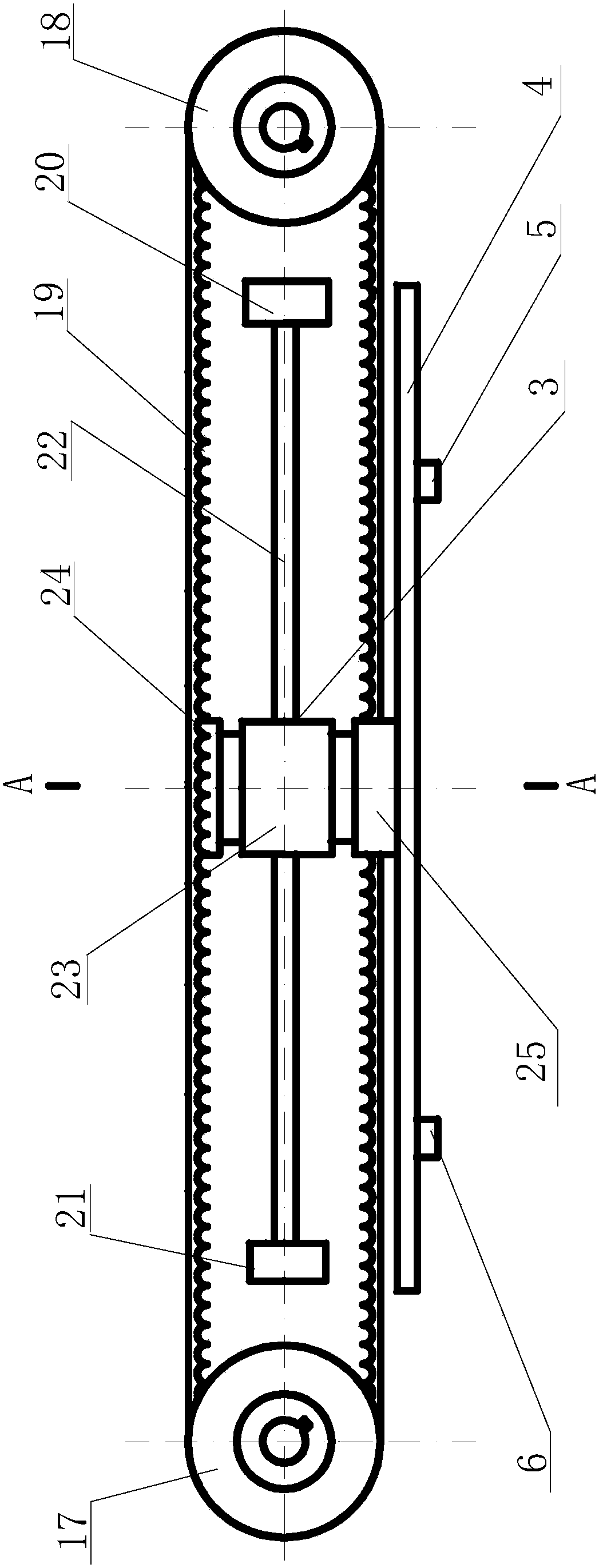

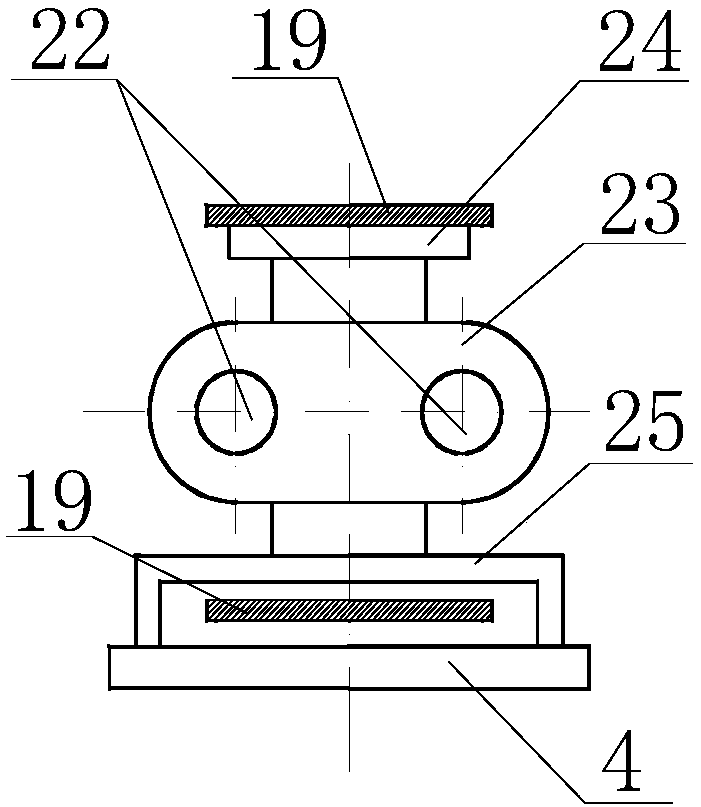

[0037] The horizontal high-speed reciprocating mechanism includes a driving mechanism and a moving splint 4 connected to the driving mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com