Method for sterilizing drinking water packing material by using pulse sterilization technology

A packaging material and drinking water technology, applied in irradiation, disinfection, etc., can solve the problems of unsatisfactory sterilization effect, traditional sterilization methods, and many sterilization procedures, so as to prevent photoreactivation, release large energy instantaneously, and reduce the number of uses Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

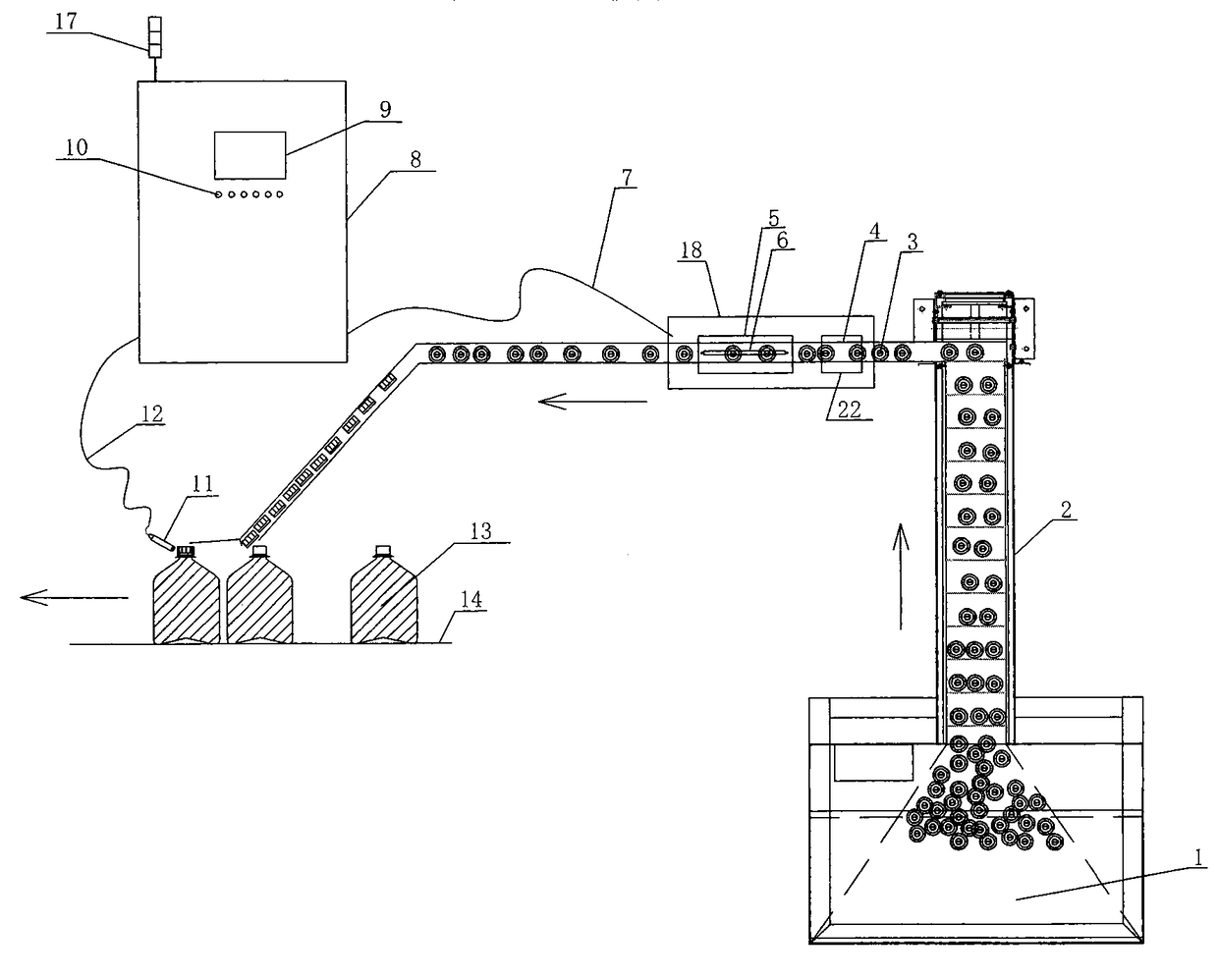

[0057] see figure 1

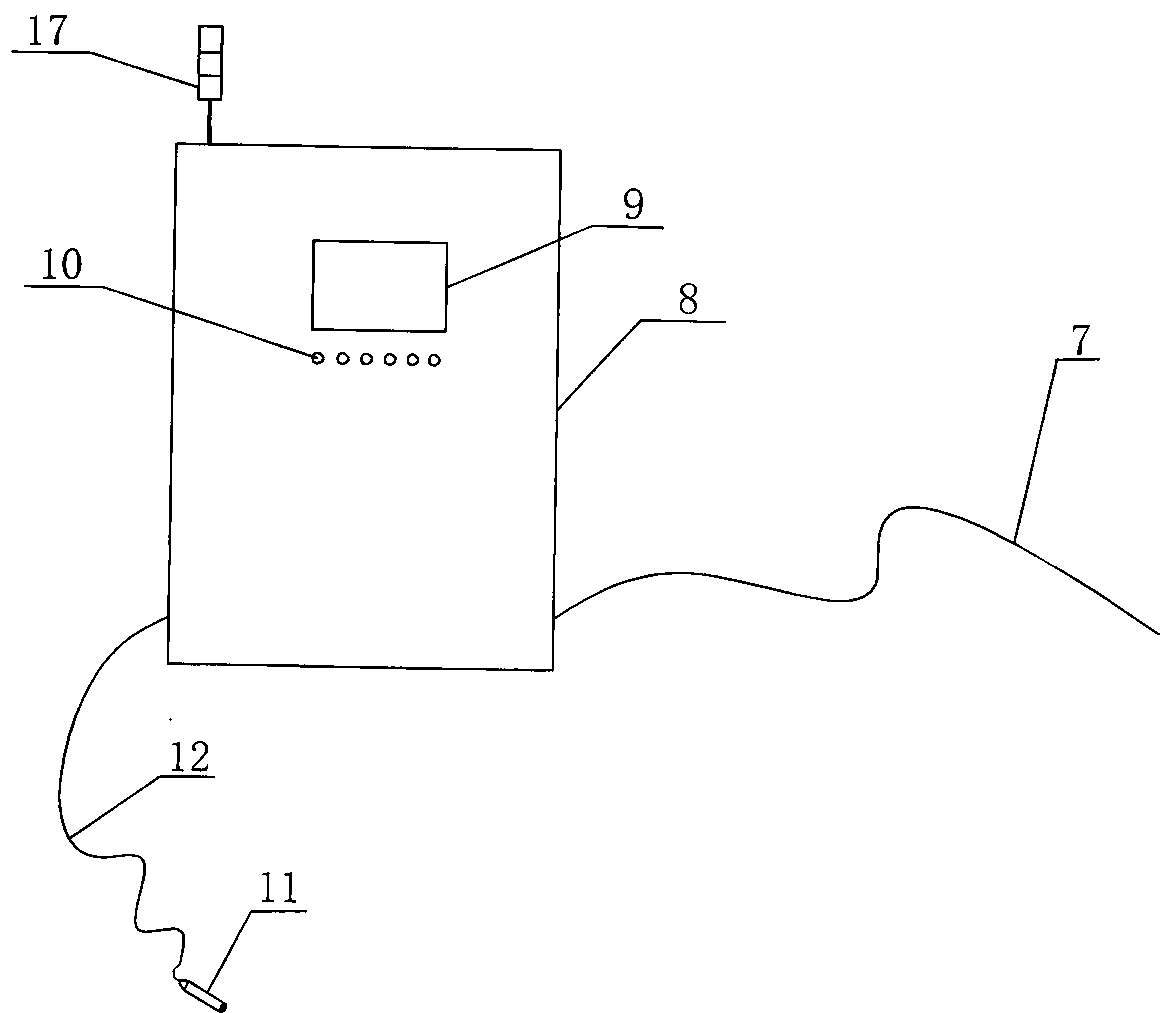

[0058] figure 1 It is a structural schematic diagram of a pulse sterilizing device for novel drinking water packaging materials in the present invention. exist figure 1 Among them, a method of applying pulse sterilization technology to the sterilization of drinking water packaging materials, said method comprises the following steps:

[0059] (1) Using pulse sterilization technology to sterilize drinking water packaging materials;

[0060] (2) Step (1) is sterilized by a pulse sterilization device adopting novel drinking water packaging material;

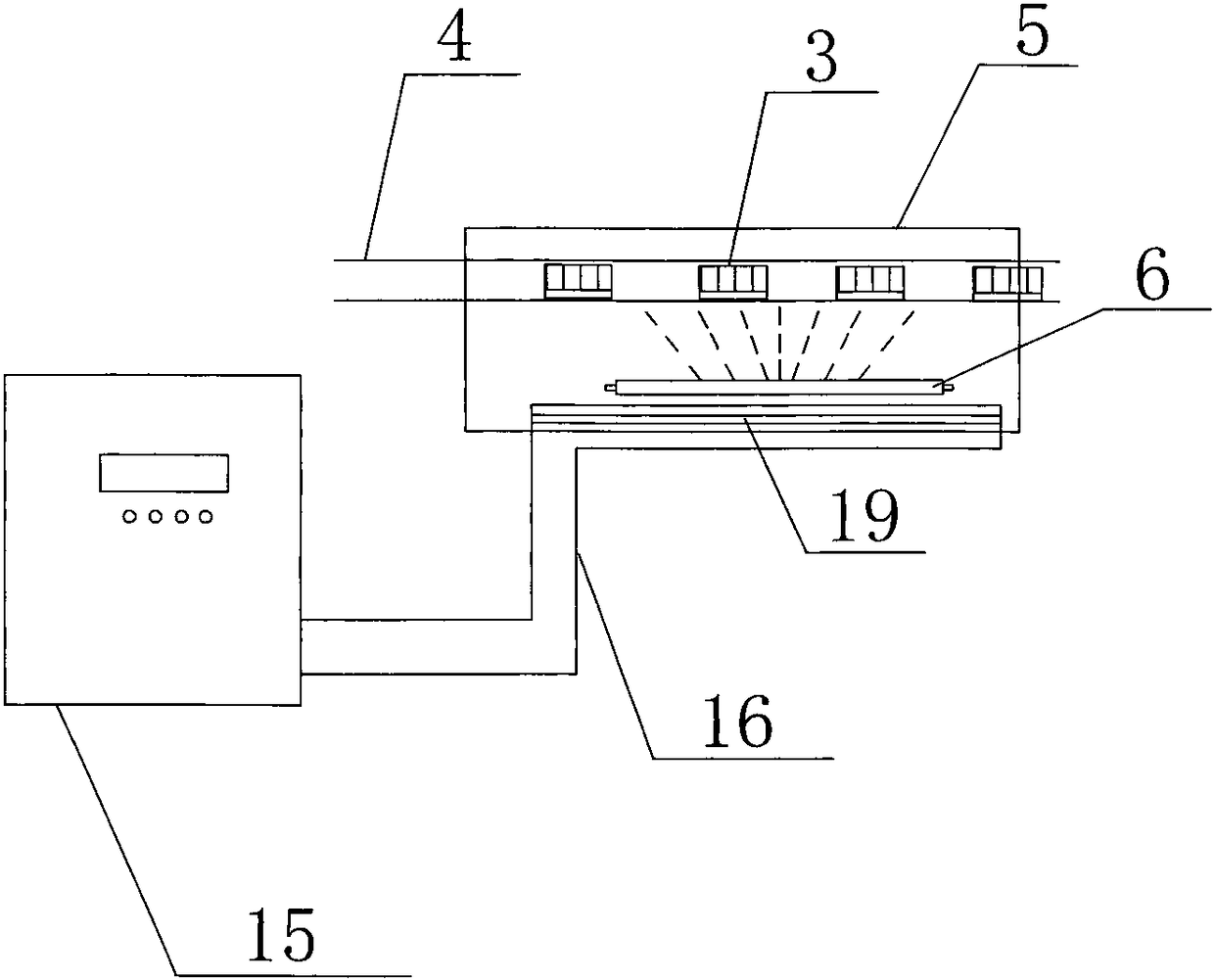

[0061] The pulse sterilizing device of the novel drinking water packaging material in step (2) comprises the bottle cap conveying device that is provided with cleaning and disinfection chamber 18 that is electrically connected with the control system and the cooling system, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com