Rotary drum drainage mechanism of horizontal spiral centrifuge

A horizontal screw and centrifuge technology, applied in the field of centrifuges, can solve the problem of inability to separate two-phase mixed materials, and achieve the effects of simple structure, simple and reliable structure, and stable and reliable function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

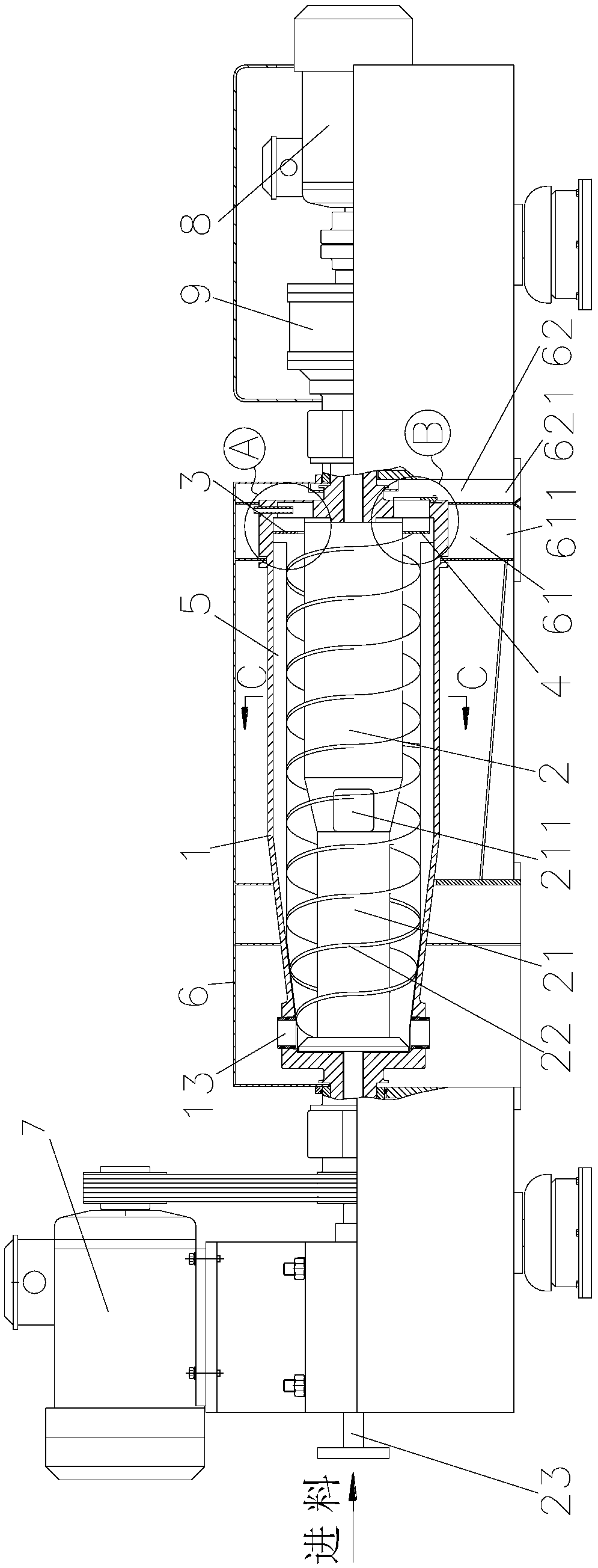

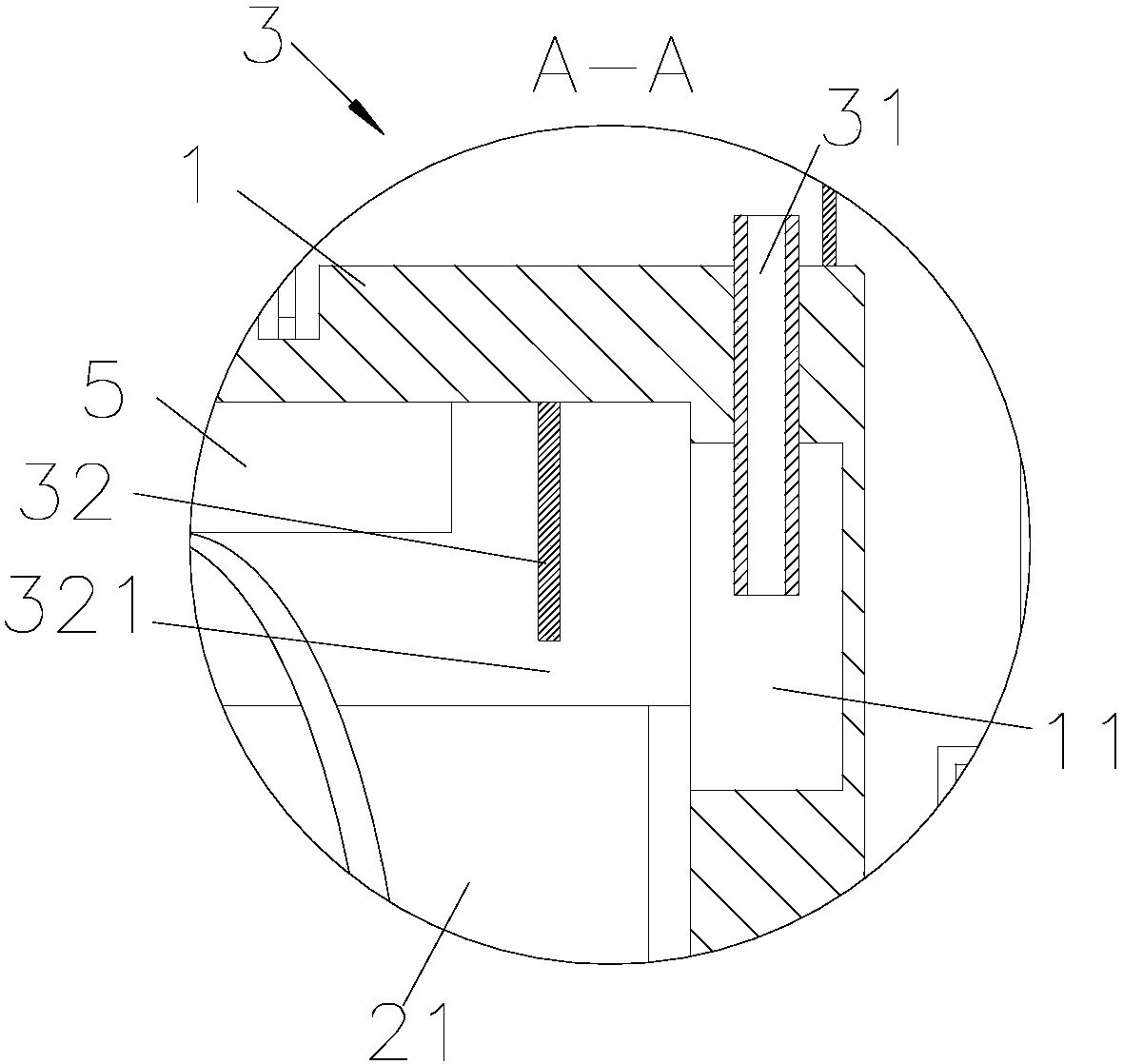

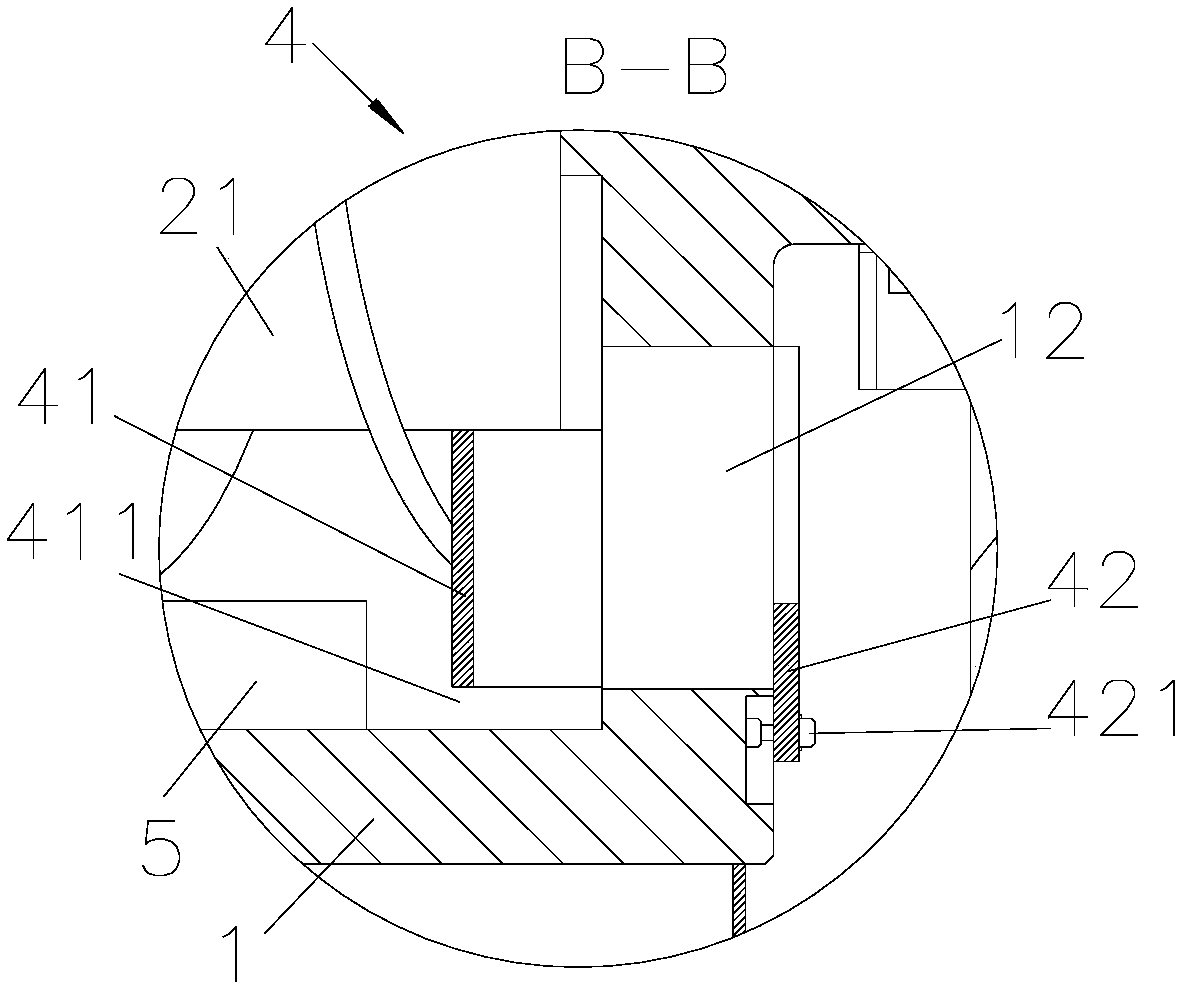

[0022] like Figure 1~4 As shown, a drum draining mechanism of a horizontal screw centrifuge is characterized in that it includes a cover 6, a drum 1 rotatably arranged in the cover 6 and a screw unloader rotatably arranged in the drum 1 2. One end of the drum 1 is driven to rotate by the main motor 7. The screw unloader 2 includes a hollow mandrel 21 and a screw pusher blade 22 arranged on the mandrel 21. The mandrel 21 is located on the other side of the drum 1. One end of one end is fixedly connected with the differential gear 9, and the differential gear 9 is driven by the auxiliary motor 8, and one end of the inner cavity of the mandrel 21 is provided with a feed pipe 23, and the mandrel 21 is provided with a The inner chamber of the drum 1 is connected to the feed port 211, and the mandrel 21 is provided with an accelerator with a distribution chamber, and the distribution chamber is respectively connected with the feed pipe 23 and the feed port 211. port 13, the other ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com