A control method for warping of hot-rolled variety steel in rough rolling

A control method and rough rolling technology, applied in the direction of metal rolling, tail end control, etc., can solve problems such as technical solutions for the prevention of production at the source of warping, and achieve the goal of improving business level and subjective initiative, enhancing intervention ability, and avoiding equipment damage. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

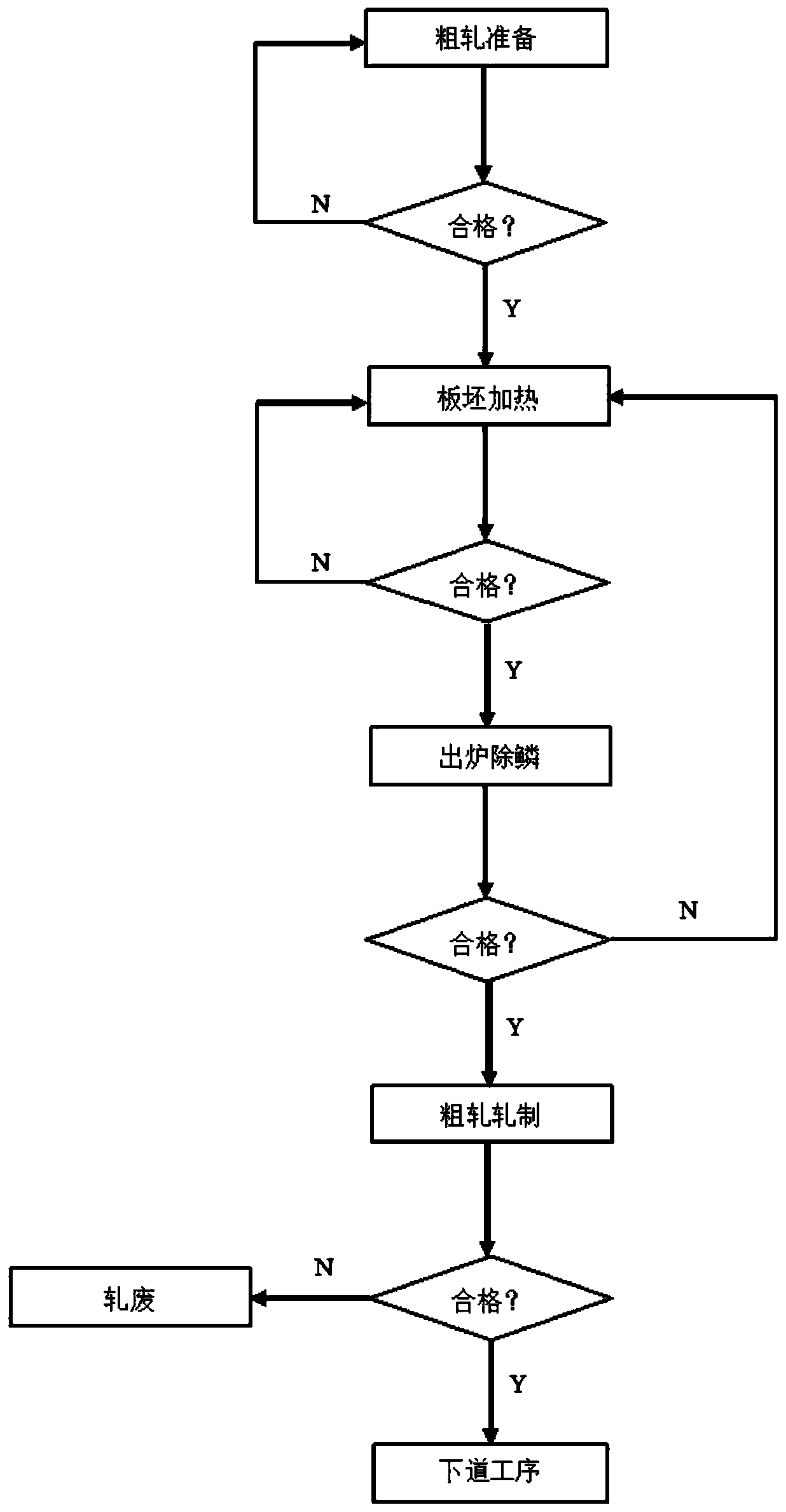

[0026] The embodiment of the present invention provides a method for controlling warping in rough rolling of hot-rolled variety steel. The warping control process includes rough rolling preparation, slab heating, furnace descaling, and rough rolling in sequence. The control method includes:

[0027] The grade of the slab is 420CL steel for wheels, and the thickness is 135mm. The slab is heated in a furnace, and the temperature of the slab is controlled to be completely uniform. There is no black mark on the end face of the slab, and there is no obvious watermark. . After the slab comes out of the furnace, it enters the descaling box for surface descaling. Two rows of descaling headers are opened, the outlet pressure of descaling water is 20MPa, and there is no iron oxide residue on the surface of the slab at the descaling outlet. After descaling, the slab enters the roughing single stand for 3 times of round-trip rolling, of which the first pass is descaling with high-pressure...

Embodiment 2

[0030] The embodiment of the present invention provides a method for controlling warping in rough rolling of hot-rolled variety steel. The warping control process includes rough rolling preparation, slab heating, furnace descaling, and rough rolling in sequence. The control method includes:

[0031] The grade of the slab is X52 pipeline steel with a thickness of 150mm. The slab is heated in a furnace, and the temperature of the slab is controlled to be completely uniform. There is no black mark on the end face of the slab, and there is no obvious watermark. . After the slab comes out of the furnace, it enters the descaling box for surface descaling. The descaling headers are opened in 4 rows, the outlet pressure of the descaling water is 18MPa, and there is no iron oxide residue on the surface of the slab at the descaling outlet. After descaling, the slab enters the roughing single stand for 3 times of round-trip rolling, of which the first pass is descaling with high-pressure...

Embodiment 3

[0034] The embodiment of the present invention provides a method for controlling warping in rough rolling of hot-rolled variety steel. The warping control process includes rough rolling preparation, slab heating, furnace descaling, and rough rolling in sequence. The control method includes:

[0035] The grade of the slab is X52 pipeline steel with a thickness of 145mm. The slab is heated in a furnace, and the temperature of the slab is controlled to be completely uniform. There is no black mark on the end face of the slab, and there is no obvious watermark. . After the slab comes out of the furnace, it enters the descaling box for surface descaling. The descaling headers are opened in 4 rows, the outlet pressure of the descaling water is 18MPa, and there is no iron oxide residue on the surface of the slab at the descaling outlet. After descaling, the slab enters the roughing single stand for 3 times of round-trip rolling, of which the first pass is descaling with high-pressure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com