Air compressor crankshaft upset-forging method and die

An air compressor and upsetting technology, which is applied in the direction of forging/pressing/hammering machinery, mechanical equipment, manufacturing tools, etc., can solve the problem of large machining allowance, damage to the fiber streamline of forging connecting rod journal, poor service strength, etc. problem, to achieve the effect of small margin, saving material and processing cost, and excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

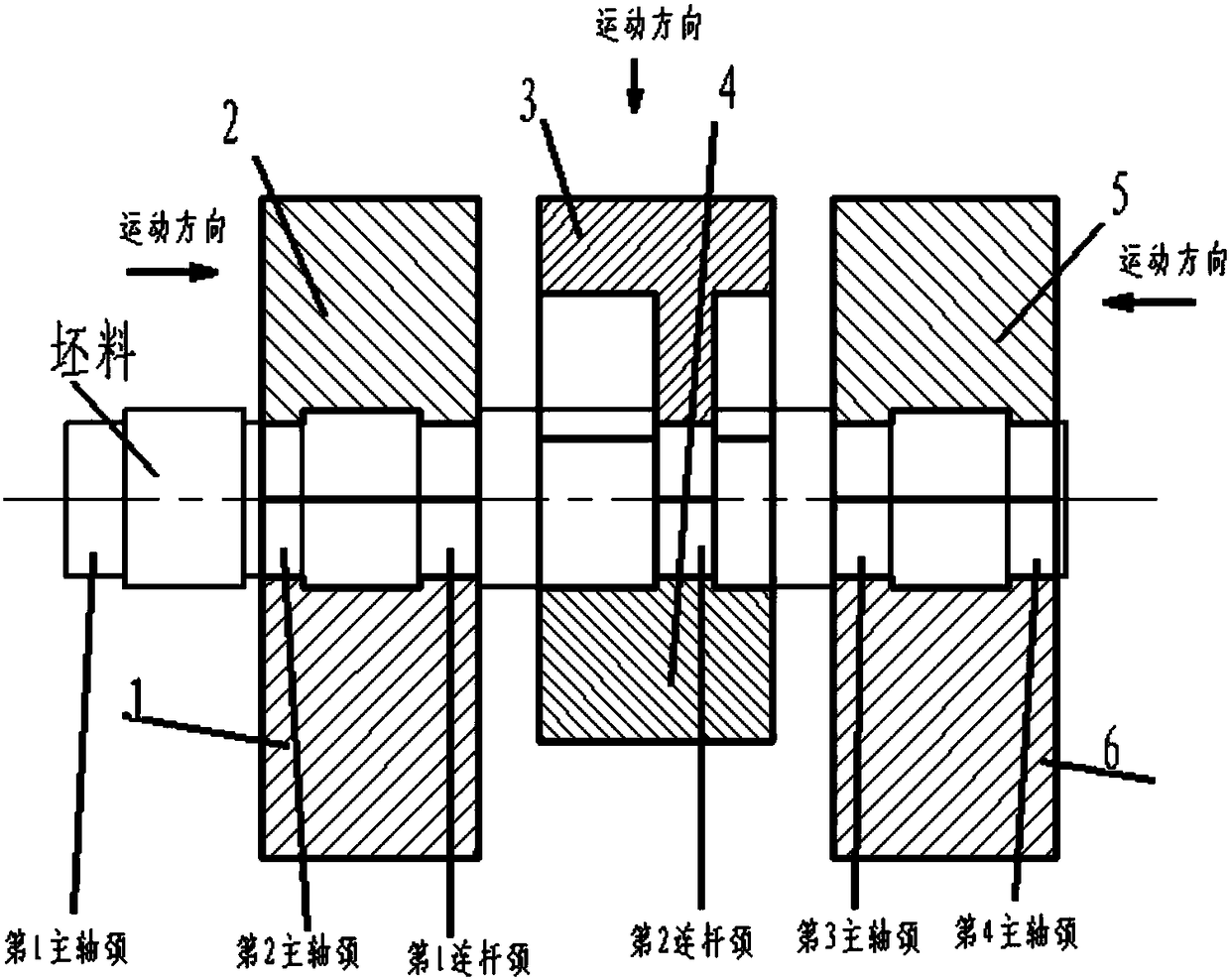

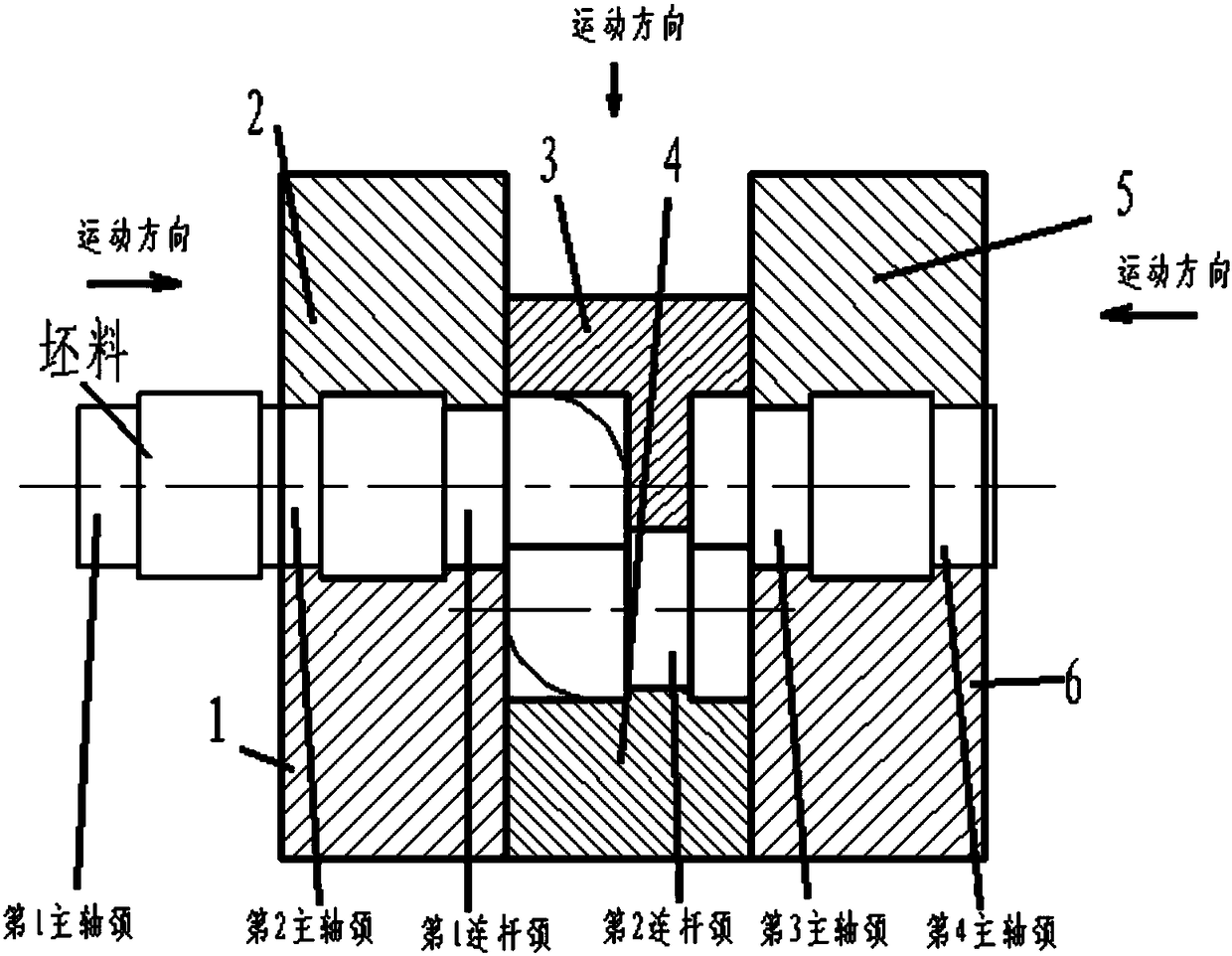

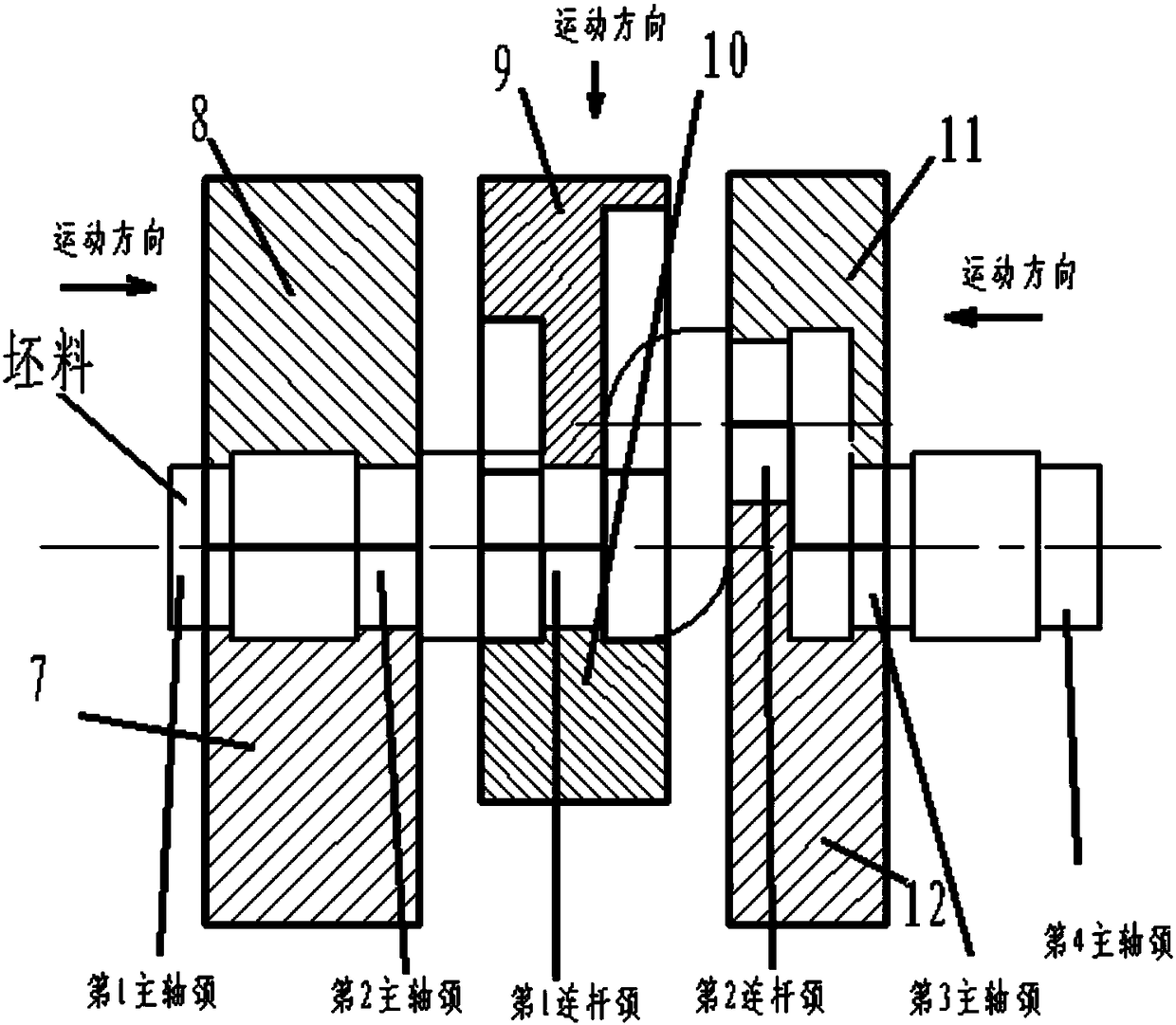

[0013] The present invention is specifically described below in conjunction with accompanying drawing, as Figure 1-Figure 4 As shown, during the initial forging and upsetting of the present invention, the heated blank is put into the mold, the upper die 3 in the middle of the upsetting forging and the lower die 4 in the middle of the upsetting forging in the initial forging hold the second connecting rod journal of the crankshaft and move in the upper part Under the action of the device, the second connecting rod neck is pushed downward to produce bending deformation, and at the same time, the first initial forging and upsetting horizontal upper die 2, the first initial forging and upsetting horizontal lower die 1, and the second initial forging and upsetting horizontal upper die 5 Under the action of the horizontal motion device, the second initial forging horizontal lower die 6 relatively moves horizontally to carry out upsetting deformation. Forging and upsetting horizonta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com