Effect-increasing and energy-saving cutting method for continuous casting steel blank

A cutting method and billet technology, which is applied in the field of continuous casting billet efficiency-enhancing energy-saving cutting, can solve the problems of large steel consumption, insufficient saving degree, undercut burning, collapse and slag hanging, etc., to achieve improved production efficiency, no carbon increase and Hardening phenomenon, the effect of smooth cutting surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] A method for increasing efficiency and saving energy for continuous casting billets, comprising the following steps:

[0026] The first step: adjust the distance between the cutting nozzle and the continuous casting billet to 30mm;

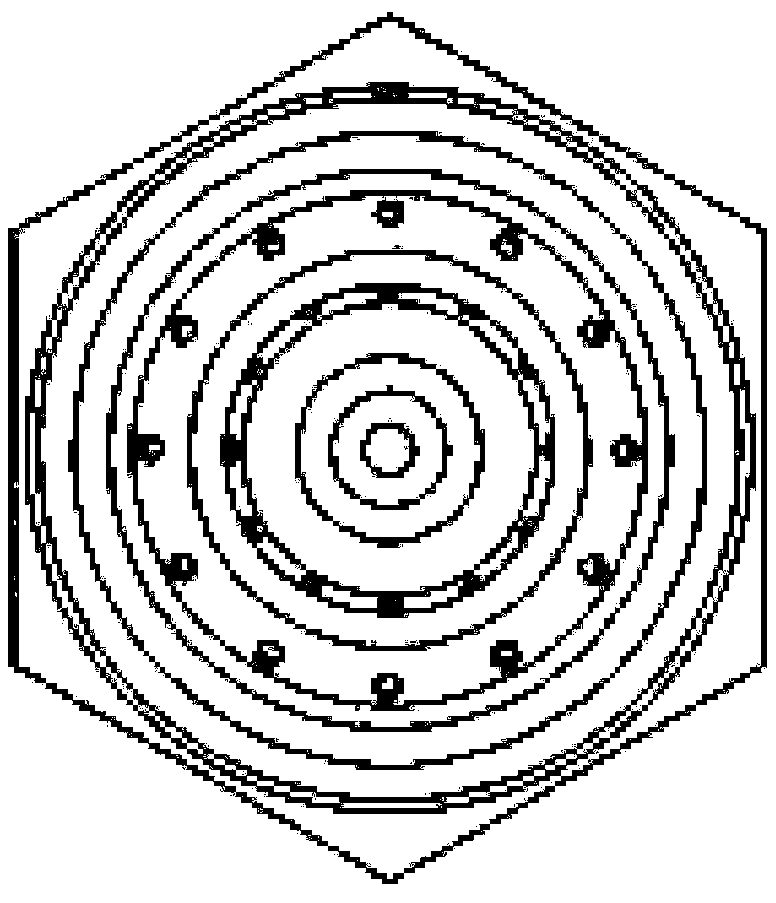

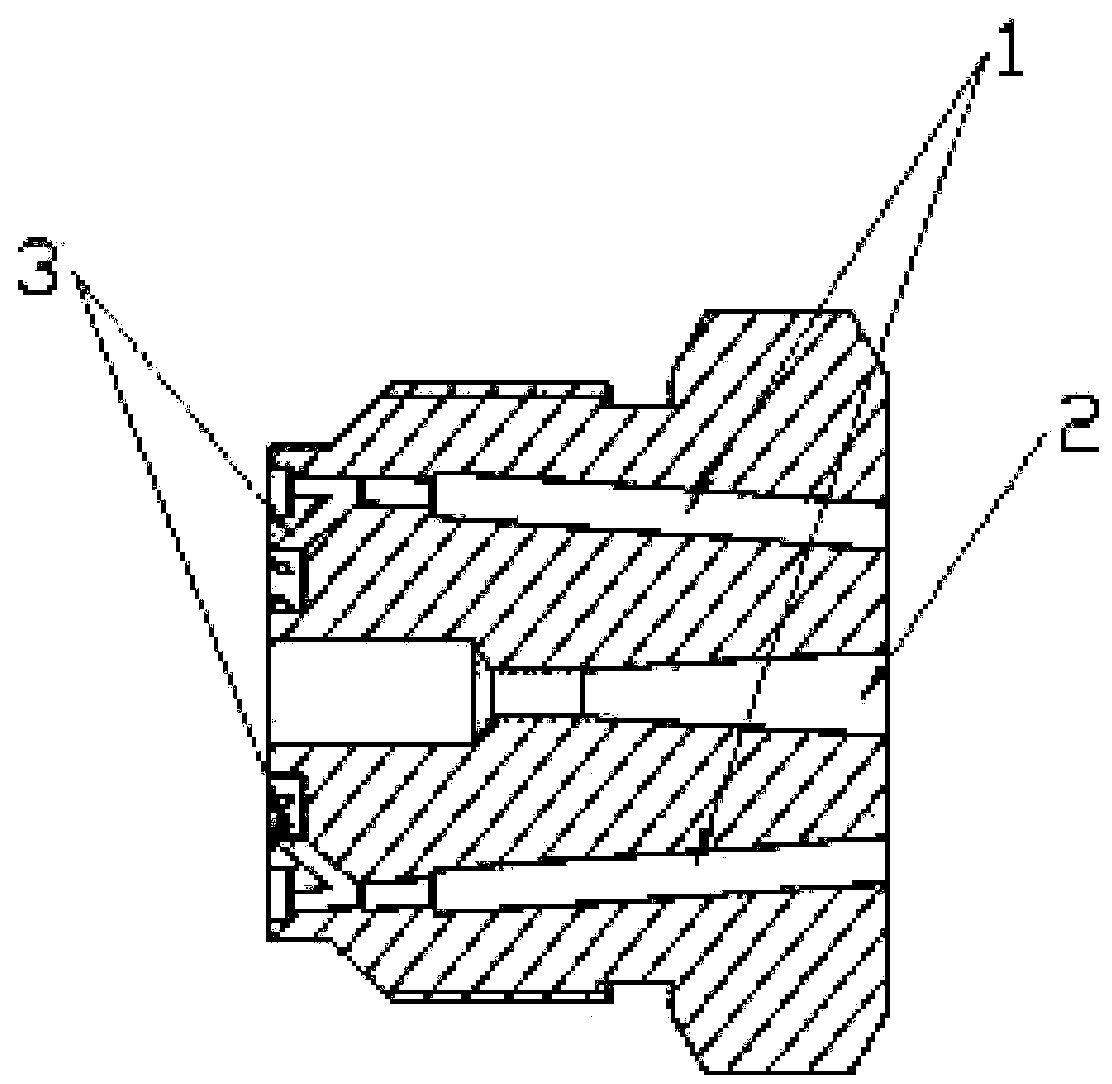

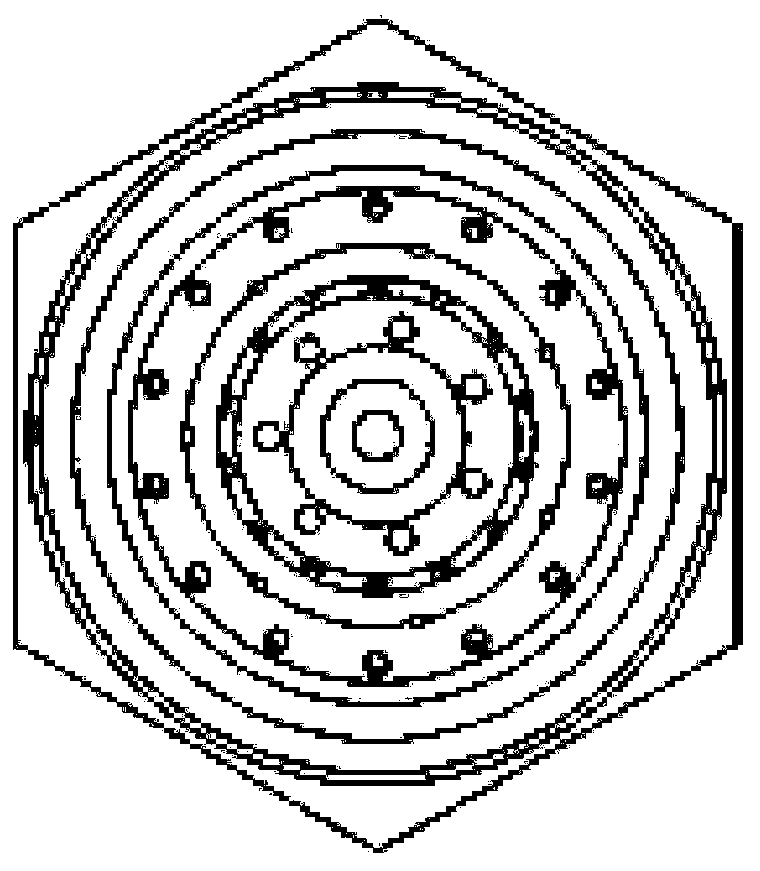

[0027] Step 2: The preheating oxygen enters the cutting nozzle through the preheating oxygen channel 3, the energy-enhancing gas enters the cutting nozzle through the energy-enhancing gas channel 1, and the cutting oxygen enters the cutting nozzle through the cutting oxygen channel 2;

[0028] Step 3: Set the preheating oxygen pressure to 0.2mpa, set the energy-saving gas pressure to 0.02mpa, set the cutting oxygen pressure to 1mpa, and start cutting.

[0029] The efficiency-enhancing and energy-saving gas is mixed by the following raw materials in weight percentage: natural gas 99.1%, synergist 9‰; the synergist includes the following components in weight percentage: methanol 35%, higher alcohol 25%, Ethyl acetate 40%.

[0030] Such as ...

Embodiment 2

[0032] A method for increasing efficiency and saving energy for continuous casting billets, comprising the following steps:

[0033] The first step: adjust the distance between the cutting nozzle and the continuous casting billet to 40mm;

[0034] Step 2: The preheating oxygen enters the cutting nozzle through the preheating oxygen channel 3, the energy-enhancing gas enters the cutting nozzle through the energy-enhancing gas channel 1, and the cutting oxygen enters the cutting nozzle through the cutting oxygen channel 2;

[0035] Step 3: Set the preheating oxygen pressure to 0.25mpa, set the efficiency and energy saving gas pressure to 0.05mpa, set the cutting oxygen pressure to 1.1mpa, and start cutting.

[0036] The efficiency-enhancing and energy-saving gas is mixed by the following raw materials in weight percentage: natural gas 99.2%, synergist 8‰; the synergist includes the following components in weight percentage: methanol 40%, higher alcohol 30%, Ethyl acetate 30%. ...

Embodiment 3

[0039] A method for increasing efficiency and saving energy for continuous casting billets, comprising the following steps:

[0040] The first step: adjust the distance between the cutting nozzle and the continuous casting billet to 50mm;

[0041] Step 2: The preheating oxygen enters the cutting nozzle through the preheating oxygen channel, the energy-efficient gas enters the cutting nozzle through the energy-saving gas channel, and the cutting oxygen enters the cutting nozzle through the cutting oxygen channel;

[0042] Step 3: Set the preheating oxygen pressure to 0.3mpa, set the efficiency and energy-saving gas pressure to 0.1mpa, set the cutting oxygen pressure to 1.2mpa, and start cutting.

[0043] The efficiency-enhancing and energy-saving gas is mixed by the following raw materials in weight percentage: natural gas 99.2%, synergist 8‰; the synergist includes the following components in weight percentage: methanol 45%, higher alcohol 35%, Ethyl acetate 20%.

[0044] Su...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com