Full-automatic metal cutting and recovering device

An automated, metal cutting technology, used in grinding/polishing safety devices, metal processing equipment, mixers with rotary stirring devices, etc. , The effect of simplifying the cleaning process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

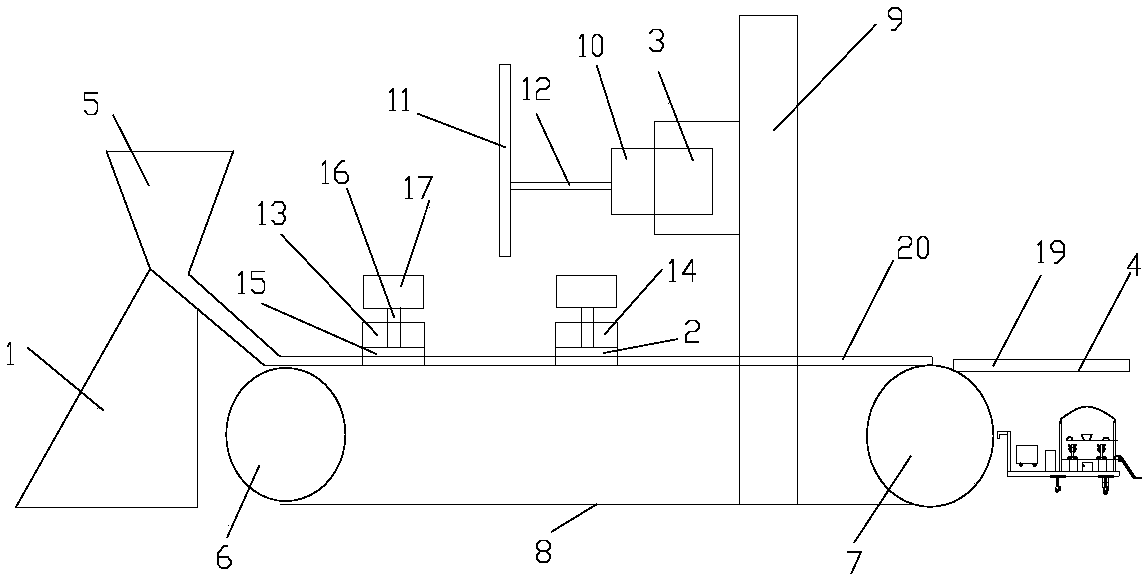

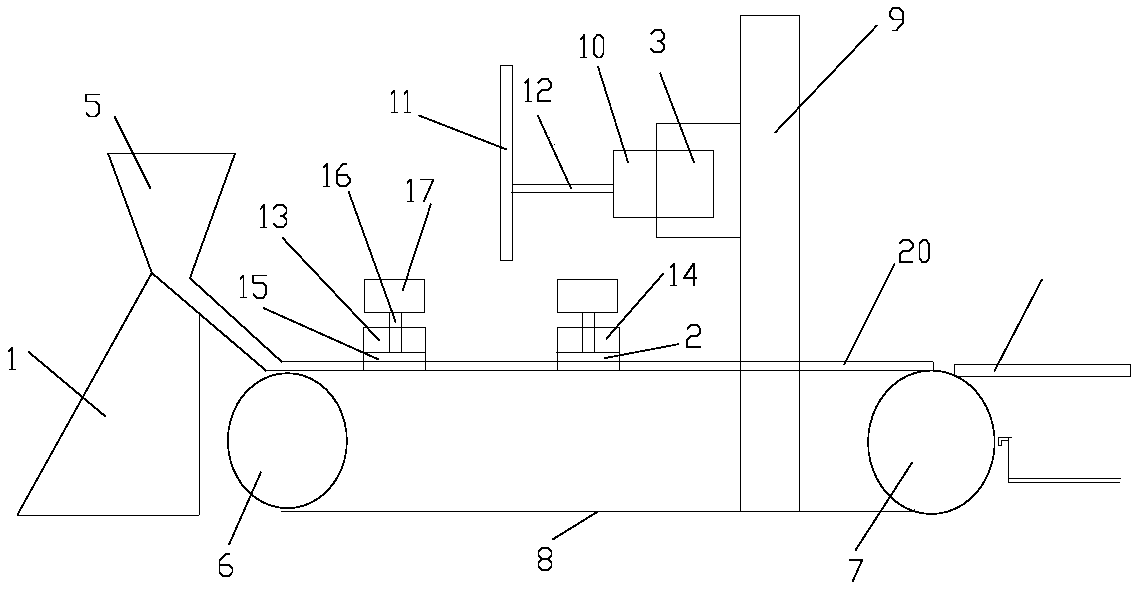

[0042] The first embodiment of the present invention: guard plates 20 are provided on both sides of the conveyor belt 8 ; rollers 21 are provided at the bottom of the receiving tube.

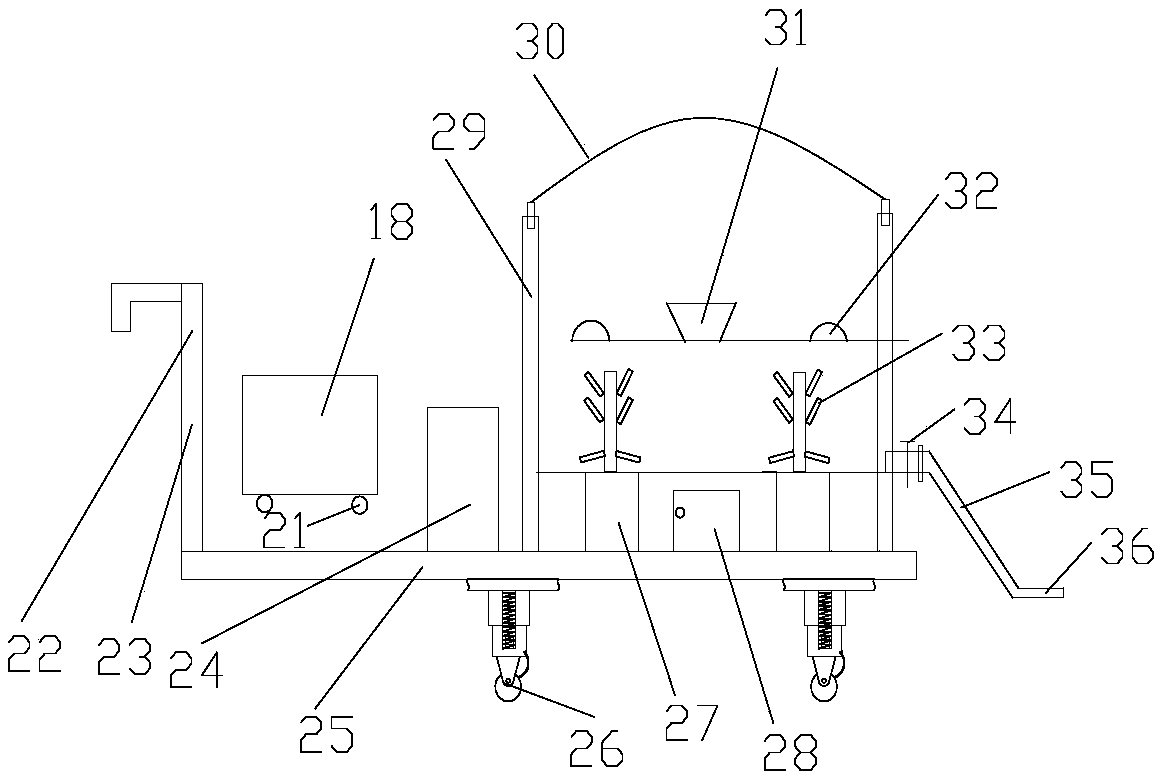

[0043] The second embodiment of the present invention: the limiting device 47 includes a pin shaft 48 arranged outside the second telescopic rod 42, a limiting handle 49 connected to the pin shaft 48 and a limiting arc rod; the limiting arc The bottom of the shaped rod matches the groove.

no. 3 example

[0044] The third embodiment of the present invention: the drive motor 10 is a three-phase asynchronous motor.

[0045] The fourth embodiment of the present invention: the feeding hopper 5 adopts an inverted cone mechanism.

no. 5 example

[0046] The fifth embodiment of the present invention: the cover is provided with a first feeding hopper 31 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com