Glass edge covering assembly and injection molding method thereof

A glass package and assembly technology, applied in the coating and other directions, to avoid compression deformation and avoid displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The content of the present invention will be further described below in conjunction with the accompanying drawings.

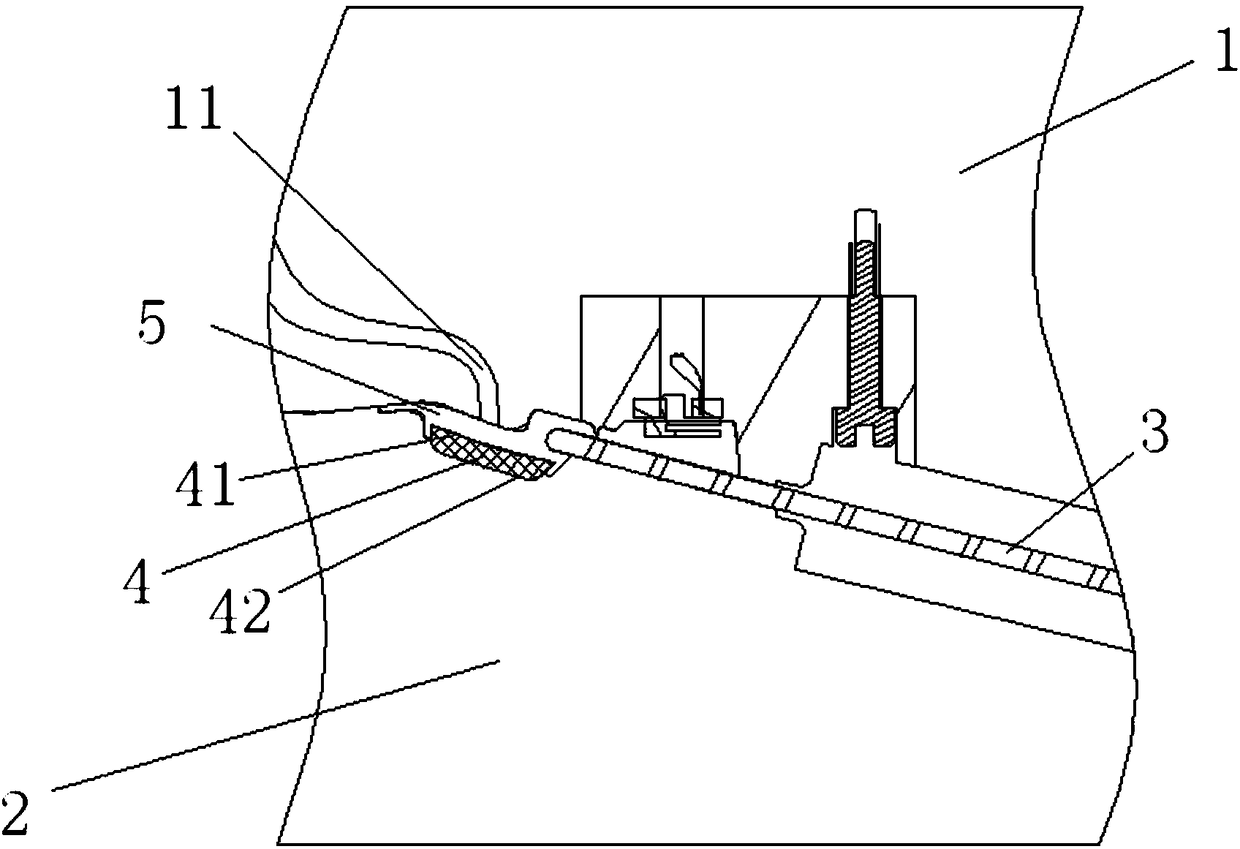

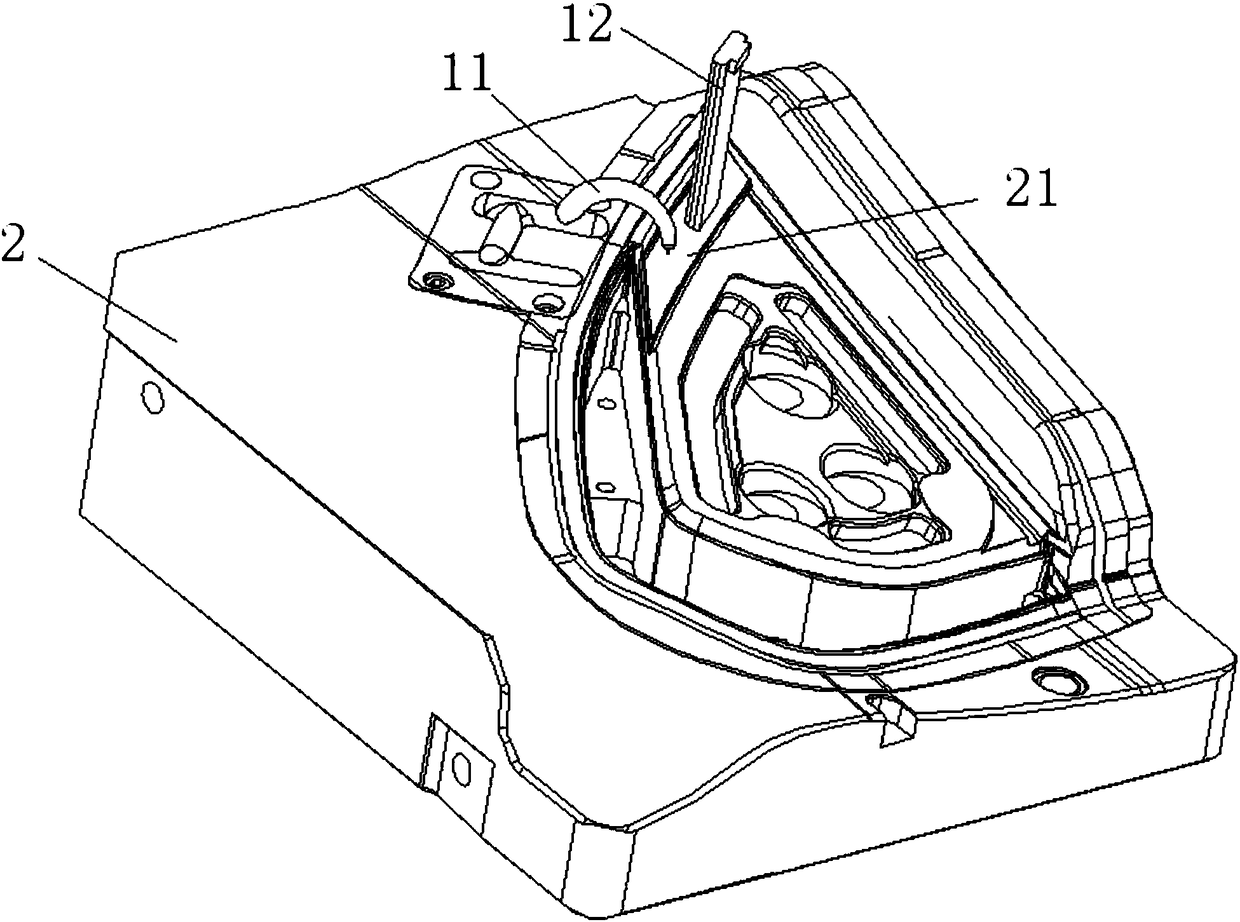

[0031] Such as Figure 1~3 As shown, the injection molding method of a glass edging assembly according to the present invention is characterized in that it comprises the following steps:

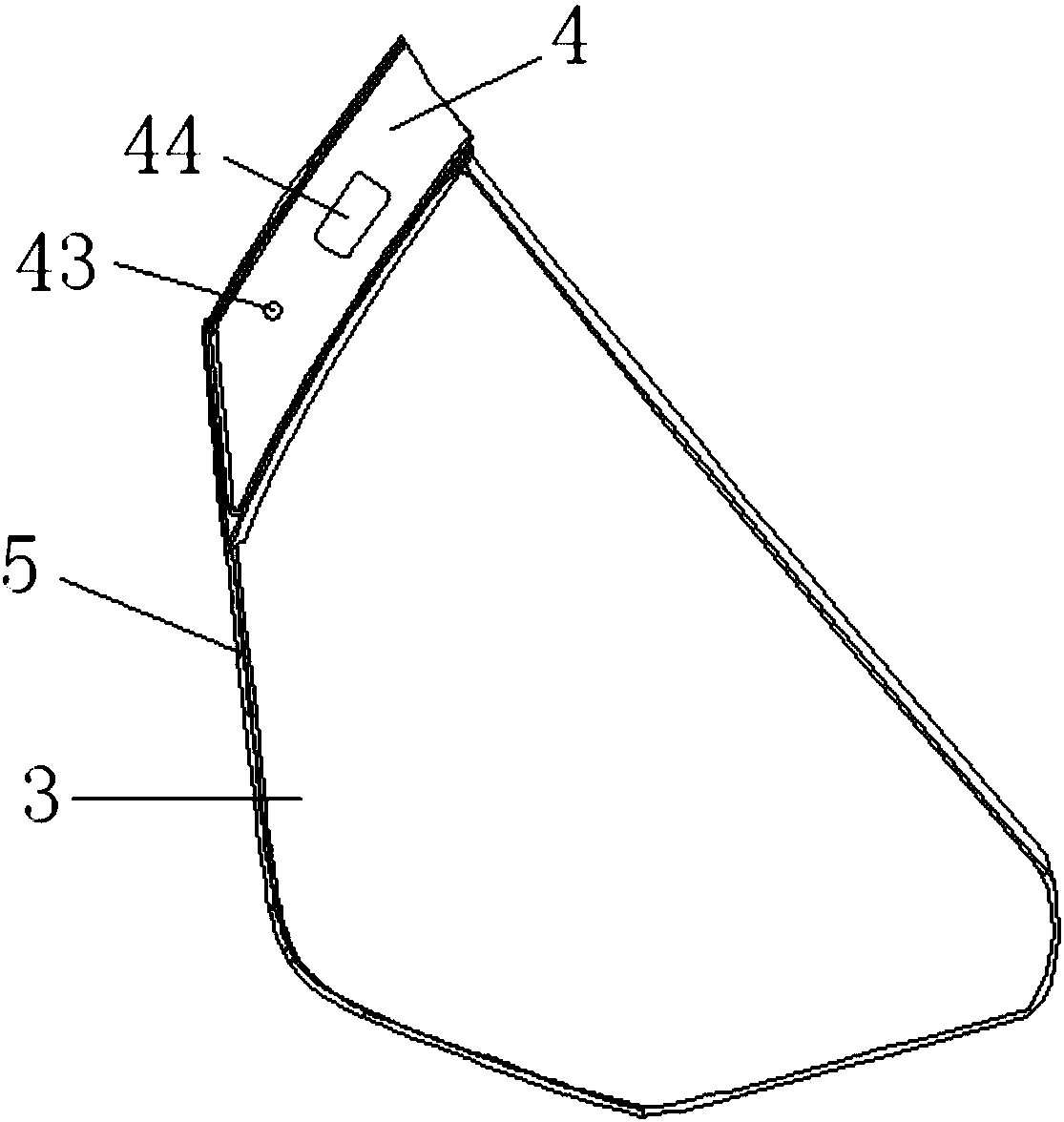

[0032] Step 1: Provide an upper mold 1 and a lower mold 2 for pairing, the lower mold 2 is provided with an insert 21, a support mechanism for supporting the glass 3 and a positioning mechanism for positioning the glass 3, the insert 21 An insert cavity for accommodating a plastic bright decoration board 4 is provided, and the plastic bright decoration board 4 includes an inner surface 41 and an outer surface 42 disposed opposite to each other;

[0033] Step 2: Place and position the plastic bright decorative plate 4 in the cavity of the insert, so that the outer surface 42 of the plastic bright decorative plate 4 fits on the bottom surface of the cavity of the insert...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com