Vehicle-roof heat insulating board

A technology for heat shields and car roofs, applied to vehicle components, movable outer sheaths, transportation and packaging, etc., to achieve the effect of accelerating gas flow, increasing surface area, and direct and stable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

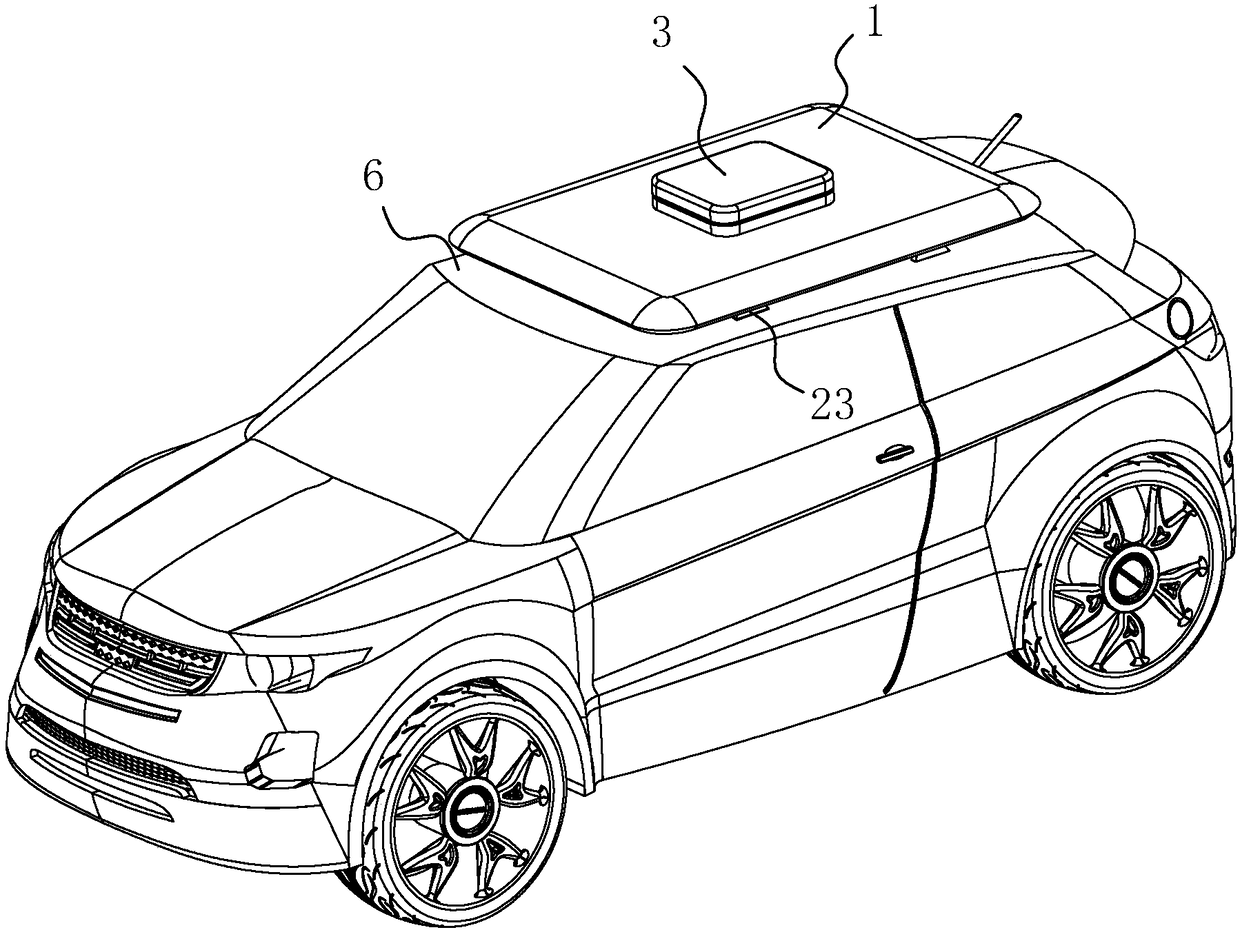

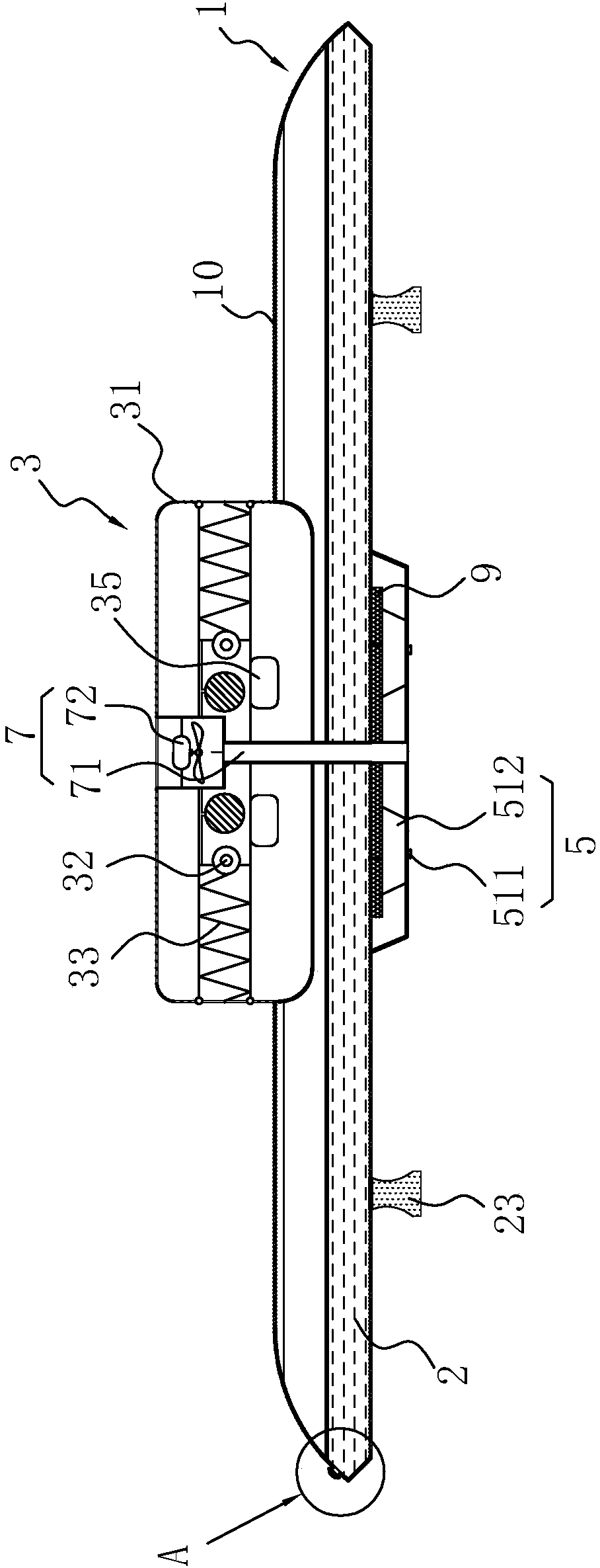

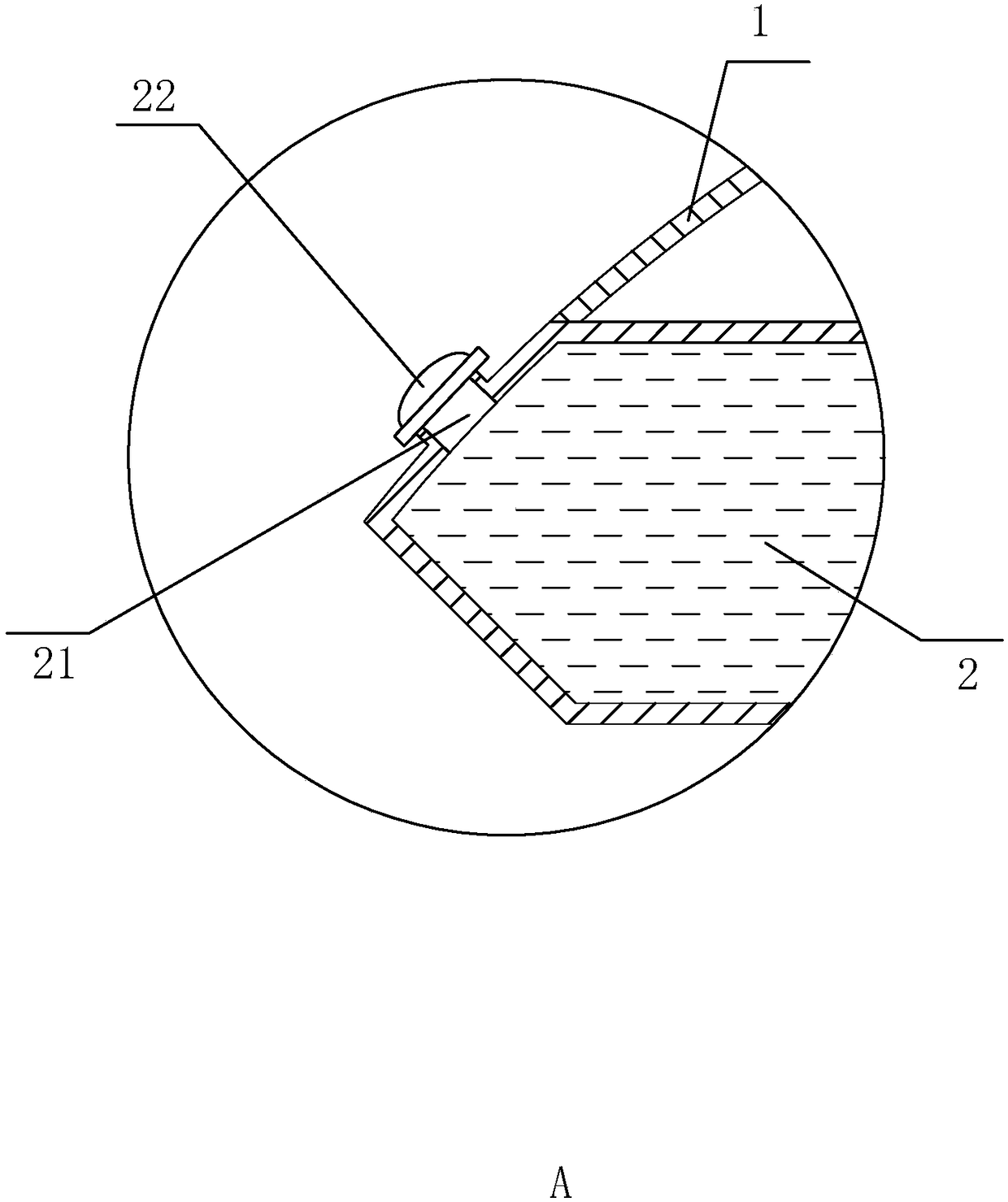

[0064] combine Figure 1~6 As shown, a roof insulation panel, such as figure 1 and figure 2 As shown, similar to the roof luggage box, it includes a heat insulation board body 1 detachably erected on the roof 6 by using a bracket 23, and a water storage layer 2 is arranged in the heat insulation board body 1, and the above water storage layer 2 is set A water injection port 21 and a sealing cover 22 for injecting water into the water storage layer 2 are provided on the side wall of the heat insulation board body 1 at the bottom of the heat insulation board body 1 at the water storage layer 2 .

[0065] In addition, the roof heat insulating board also includes an automatic car covering device 3 arranged on the heat insulating board body 1 for unfolding or retracting the car covering. Similar to the existing automatic car cover, when the car cover is unfolded, such as Figure 4 As shown, a stable heat-insulating space 4 is formed between the car cover and the car body, and t...

Embodiment 2

[0093] Such as Figure 8 As shown, a roof heat insulation board differs from Embodiment 1 in that the atomization spray assembly 5 includes a plurality of ultrasonic atomizers 521 arranged at the bottom of the heat insulation board, and the liquid storage tanks of the ultrasonic atomizers 521 522 communicates with the water storage layer 2. When the ultrasonic nebulizer 521 is working, the start-up terminal of the ultrasonic nebulizer 521 , the driving power supply and the temperature-sensitive switch assembly 8 form an electric circuit. The ultrasonic atomizer 521 can use the moisture stored in the water storage layer 2 for atomization. The advantage of the ultrasonic atomizer 521 is that it has low noise, less energy required for atomization, mature technology and easy driving.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap