Rail antiskid device for cars of coke oven and antiskid method

A locomotive track and anti-skid device technology, applied in the furnace safety device, coke oven, petroleum industry and other directions, can solve the problems of the vehicle not being able to decelerate in time, unable to judge the track cleaning in time, the vehicle starting slowly, etc., to achieve ingenious design, safety and reliability. Running control, compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

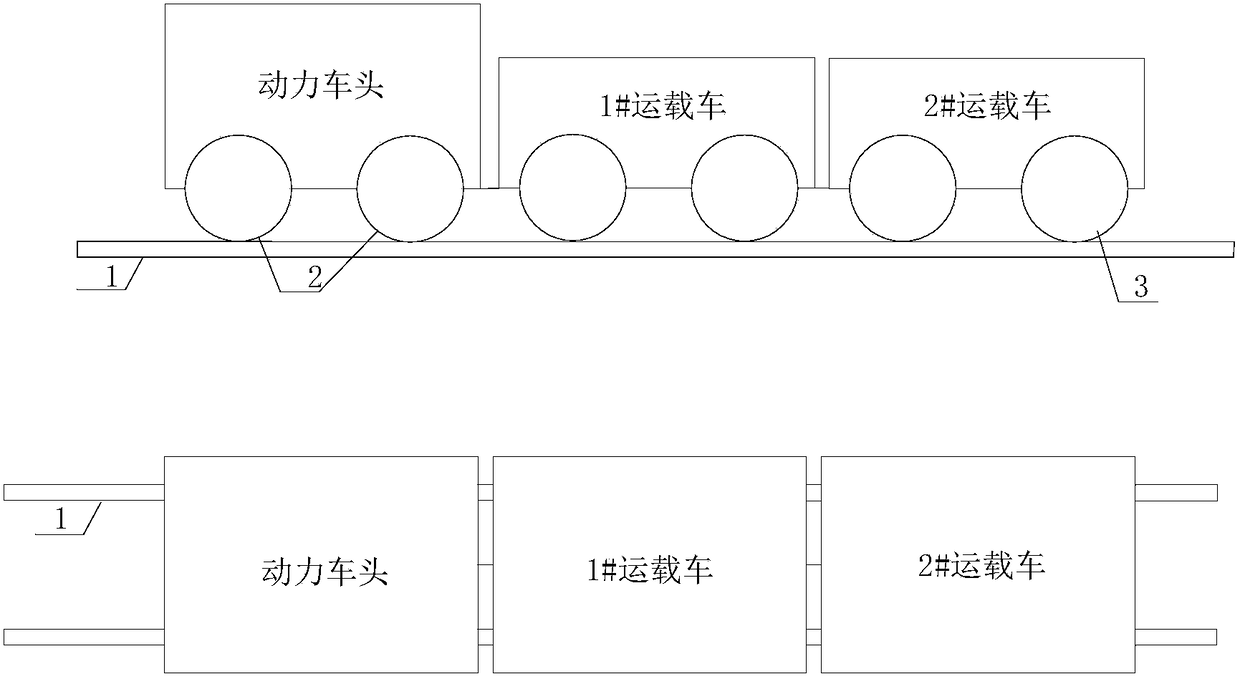

[0015] Embodiment 1: see figure 1 , taking the electric locomotive as an example, the electric locomotive consists of three car bodies: the front, the 1# coke can carrier and the 2# coke can carrier, the front contains two pairs of power wheels, and each carrier contains two pairs of driven wheels. In the original running system, the front of the car drags the carrier to run, and the power wheel of the front of the car accelerates and decelerates based on the friction with the track. Due to the large load mass, the friction coefficient of the power wheel to the track is required to be high. Once the friction coefficient is reduced , slippage will occur. Since the vehicle wheel is a driven system, the friction coefficient of the track is low, and it always rolls on the track in actual use without slipping.

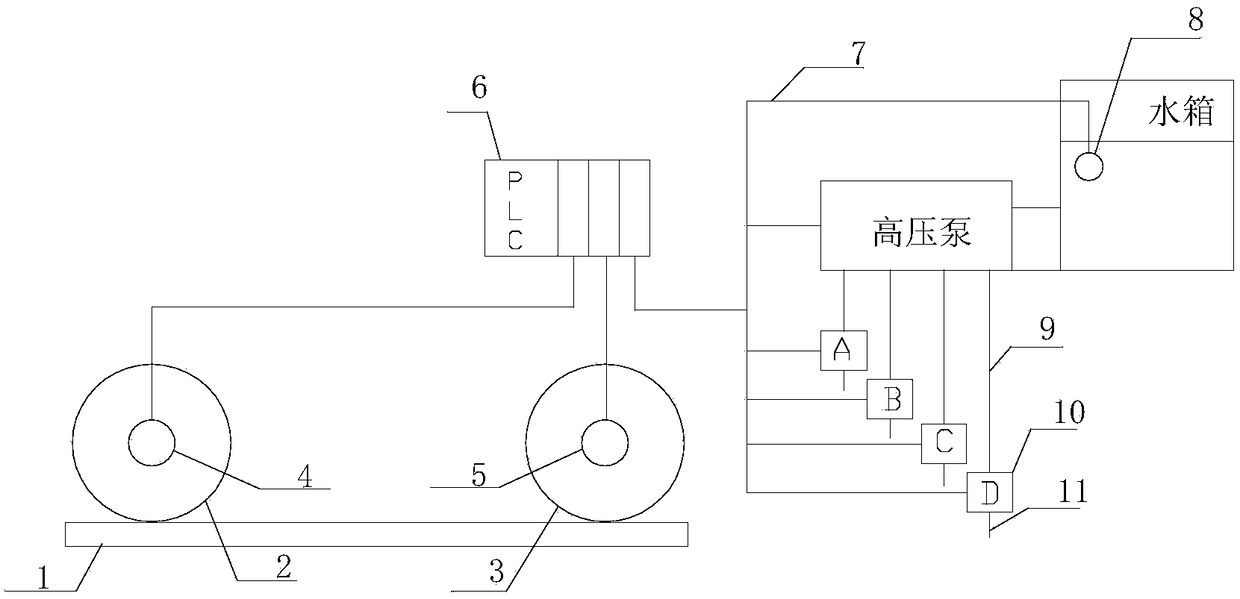

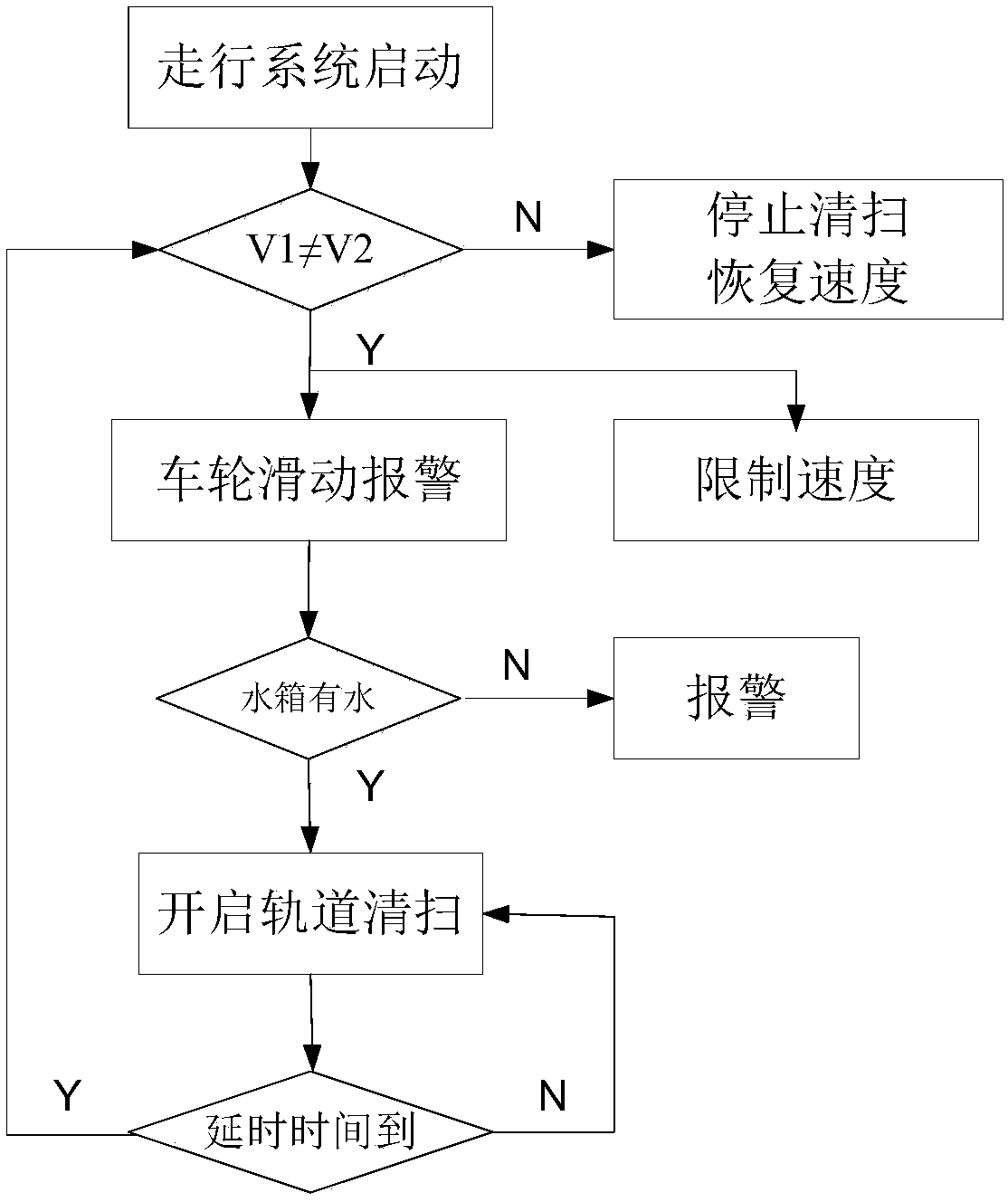

[0016] refer to Figure 2-4 , install the locomotive anti-skid device on the electric locomotive, install the driving wheel speed measuring encoder 4 on the front power w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com