Roof super waterproof structure and construction method

A waterproof structure and waterproof component technology, which is applied to roof coverings, building roofs, roof insulation materials, etc., to avoid air pollution, ensure waterproof performance, and improve thermal insulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings.

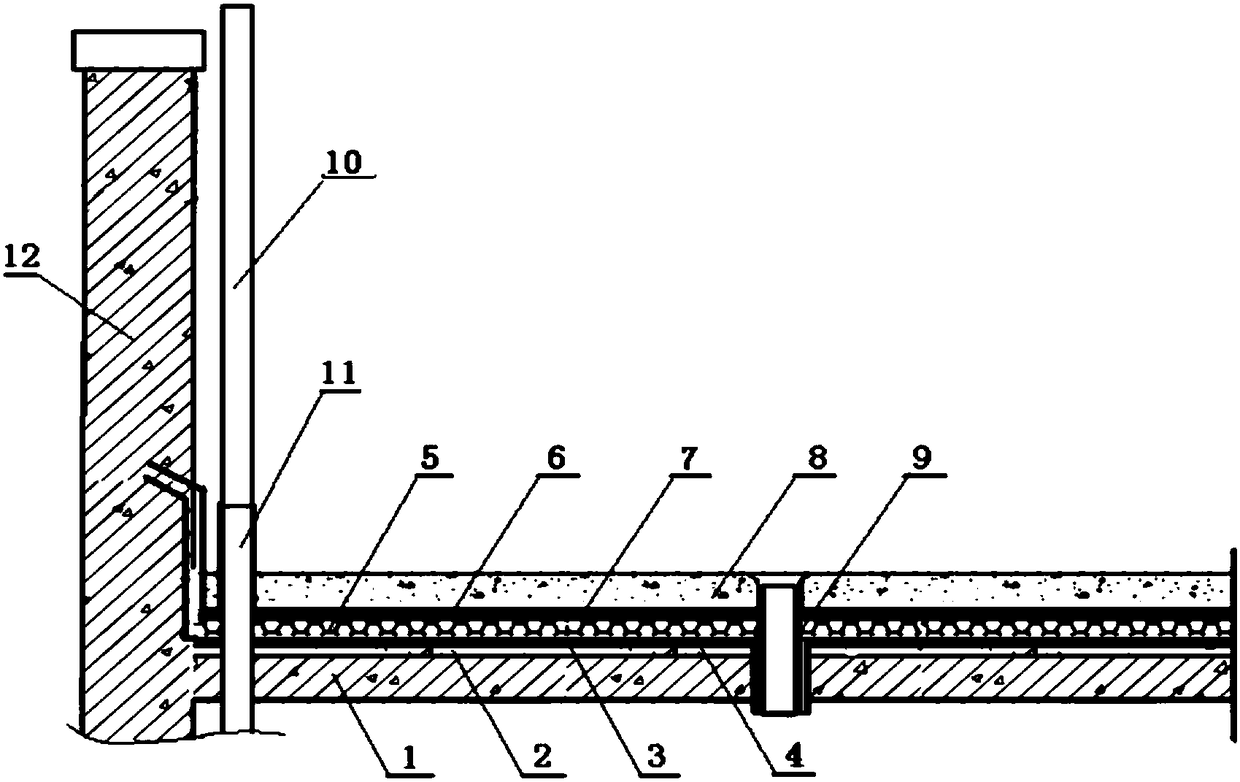

[0045] see Figure 1 to Figure 8 Shown: roof super waterproof structure, including the fine stone concrete layer 8 above the roof, the reinforced concrete structure layer 1 below the roof, and the leveling layer 2 above the reinforced concrete structure layer;

[0046] A buffer layer 3 is laid on the leveling layer 2, and the buffer layer is polyethylene foam tiled on the leveling layer, and there is no bonding between the leveling layer, and the overlapping parts of the polyethylene foam are made of Spot welding connection as a whole;

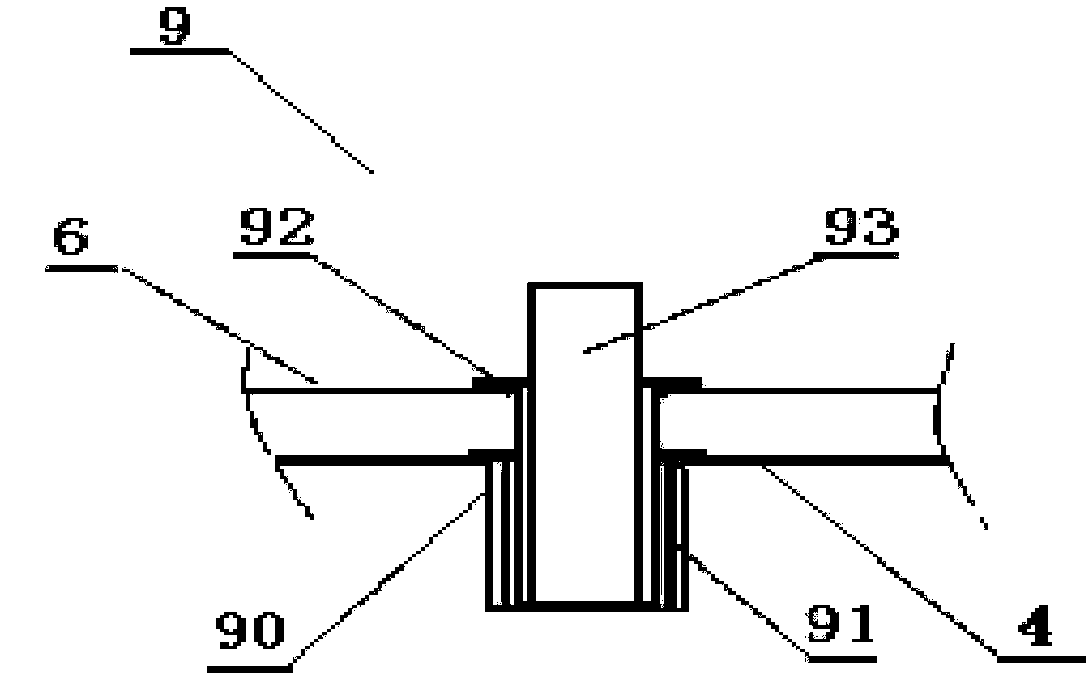

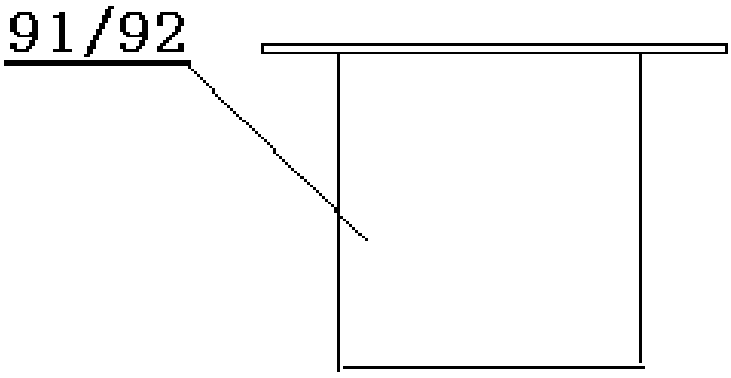

[0047] A super-strong waterproof layer 4 is laid on the buffer layer 3, and the super-strong waterproof layer is made of polyethylene film and is laid on the buffer layer without bonding with the buffer layer. , The overlapping parts of the polyethylene film are welded by single seam and connected as a whole; a buffer layer is laid o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com