Gap measuring device for thermal state tyre of cement rotary kiln, and application method for gap measuring device

A cement rotary kiln and measuring device technology, which is applied in the direction of mechanical clearance measurement, instruments, measuring devices, etc., can solve the problems of large access, impractical measurement, sliding, etc., and achieve the effect of convenient use, good effect and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

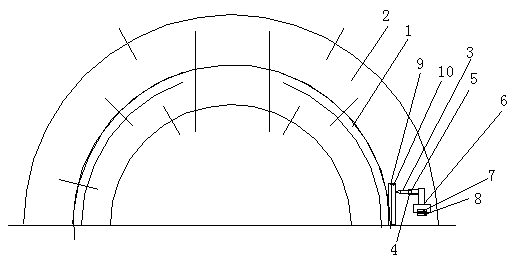

[0020] Such as figure 1 , 2 As shown, a cement rotary kiln hot tire gap tester, including: cement rotary kiln shell 1, kiln wheel 2, is characterized in that: it is also provided between the cement rotary kiln shell 1, kiln wheel 2 Set between: the marking body of the marked travel track set in the gap with the cement rotary kiln shell;

[0021] A telescoping sleeve structure that can be connected with the marking body to control the stretching of the marking body; the marking body is a pencil 3 arranged in the telescopic sleeve structure.

[0022] Connect the connection structure between the cement rotary kiln cylinder body 1 and the telescopic sleeve structure; the telescopic sleeve structure includes a pen cover body 4 and a telescopic spring 5 arranged in the pen cover body 4 and a connecting seat 6 arranged at the bottom of the pen cover body 4, The position of the connection structure is the first connection magnet 7 arranged at the bottom of the connection seat 6 and ...

Embodiment 2

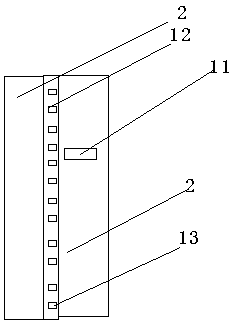

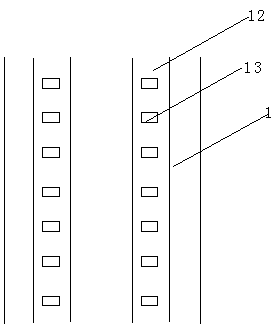

[0026] Such as image 3 , 4 As shown, another cement rotary kiln thermal tire gap tester includes: cement rotary kiln cylinder 1, kiln tire belt 2, and is characterized in that: a cement rotary kiln cylinder 1, kiln tire belt 2 is set between Infrared emitter 11, and a group of infrared collection line belts 12 arranged in gaps are arranged on cement rotary kiln shell 1, gaps are arranged between two infrared collection line belts 12, and two infrared collection line belts are evenly distributed longitudinally The dot matrix identification block 13 of the infrared emitter 11 and the array identification block 13 on the 2 infrared collection line belts 12 after the cement rotary kiln shell 1 and the kiln wheel belt 2 are operated, and at the same time, When there is a gap between the kiln shell and the inner circle of the wheel belt, the contact array recognition block 13 of the infrared emitter 11 stroke presents a curved motion trajectory, which is approximately a semicircul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com