Quick calibration system of motion platform and calibration method

A motion platform and calibration system technology, which is applied to measuring devices, instruments, and optical devices, can solve the problems of high cost of laser interferometers, unsuitable platform calibration, and cumbersome setting process, so as to reduce manpower and material costs and simplify method steps. , the effect of improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be clearly and completely described below in conjunction with specific implementation methods and accompanying drawings.

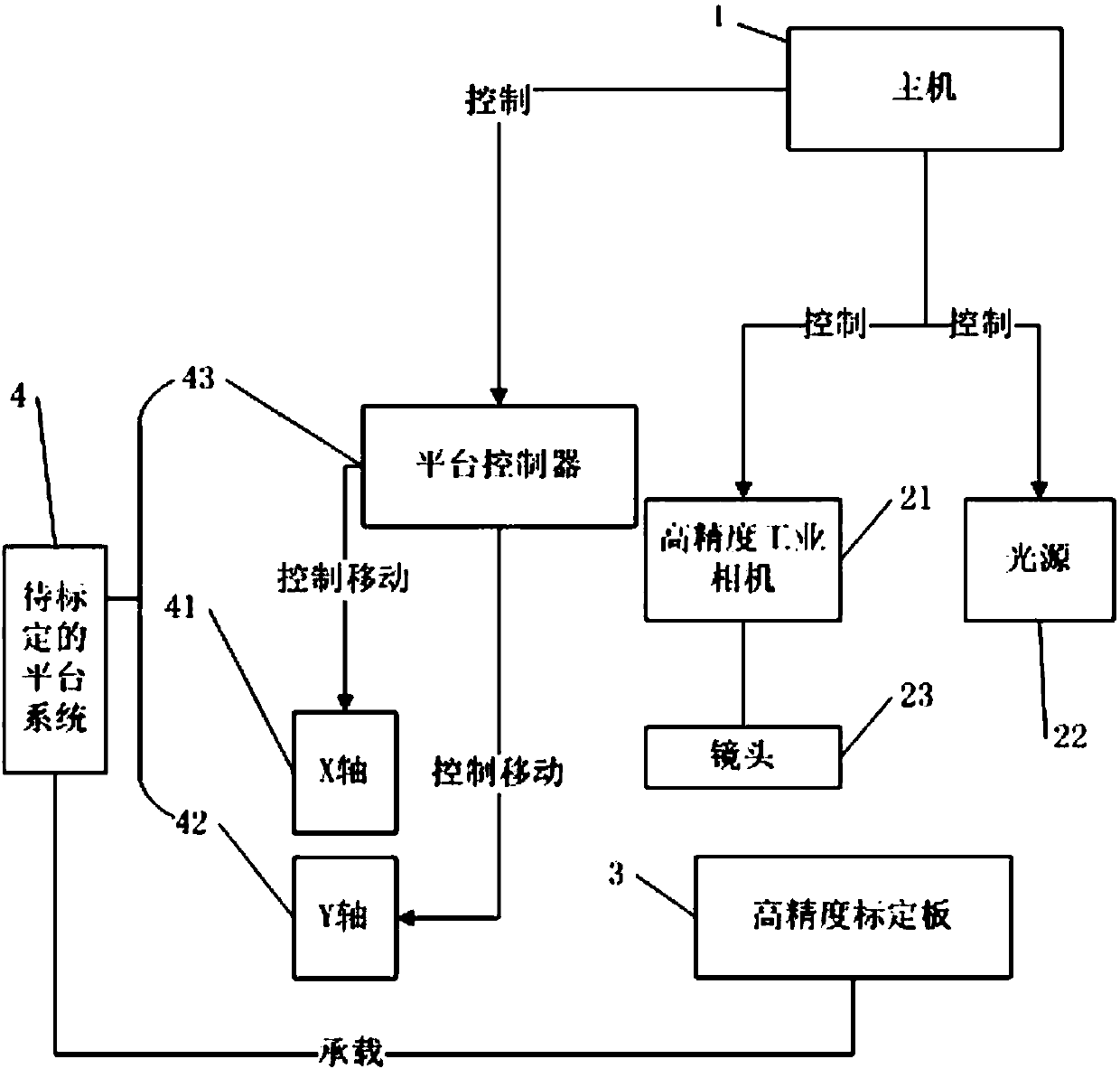

[0040] Such as figure 1 As shown, the rapid calibration system of the motion platform of the present invention includes a computer 1, a vision system 2, a high-precision calibration board 3 and a platform system 4 to be calibrated.

[0041] Computer 1 is one of personal computer, industrial computer or server. The computer is used for the calculation in the image processing process, the control of the automatic calibration process and the calculation of the final two-dimensional MAPPING data.

[0042] The vision system 2 includes a high-precision industrial camera 21, a light source 22, and a lens 23; the vision system 2 has corrected the lens distortion, and can calculate the relationship between the pixel difference and the physical length. The error introduced by the calculation result is abou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com