Method for measuring carbon content of fly ash in power station boiler

A technology of fly ash carbon content and measurement method, applied in electrical digital data processing, instruments, design optimization/simulation, etc., can solve the problem of undiscovered fly ash carbon content, etc. Fast, sensitive, high-sensitivity results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

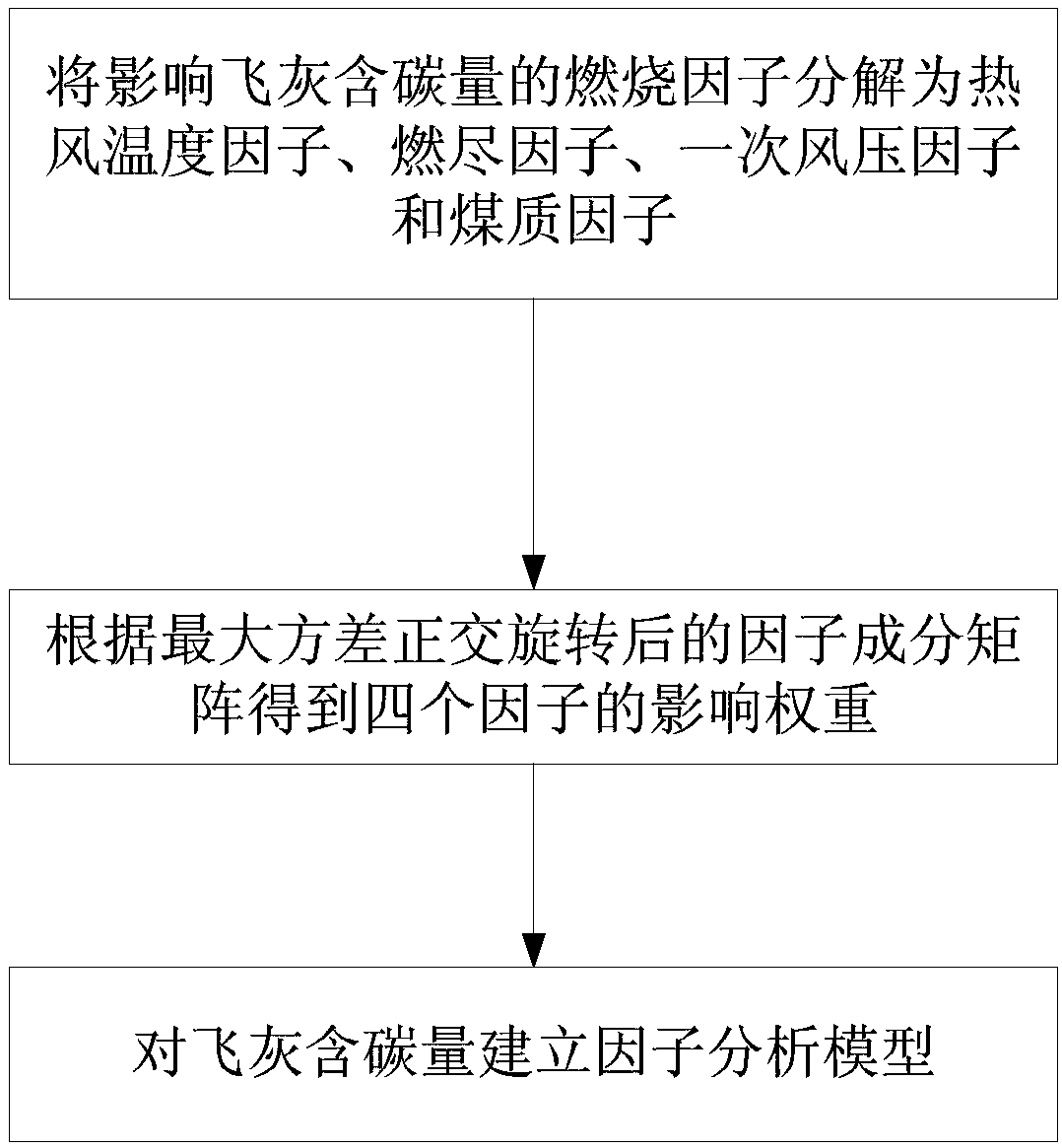

[0063] see figure 1 , a method for measuring carbon content in fly ash of a utility boiler, comprising the steps of:

[0064] Step 1: Decompose the combustion factors affecting the carbon content of fly ash into hot air temperature factors, burnout factors, primary air pressure factors and coal quality factors;

[0065] Step 2. According to the orthogonal rotation method, the influence weights of the four factors are obtained by using the factor component matrix after the maximum variance orthogonal rotation, and a factor analysis model is established for the carbon content of the fly ash;

[0066] Step A: According to the orthogonal rotation method, the factor analysis model of the carbon content of the fly ash is obtained by using the factor component matrix after the maximum variance orthogonal rotation, specifically:

[0067] Carbon content of fly ash=-0.248F1+0.871F2+0.243F3-0.083F4...(1)

[0068] Among them: F1 is the hot air temperature factor, F2 is the burnout facto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com