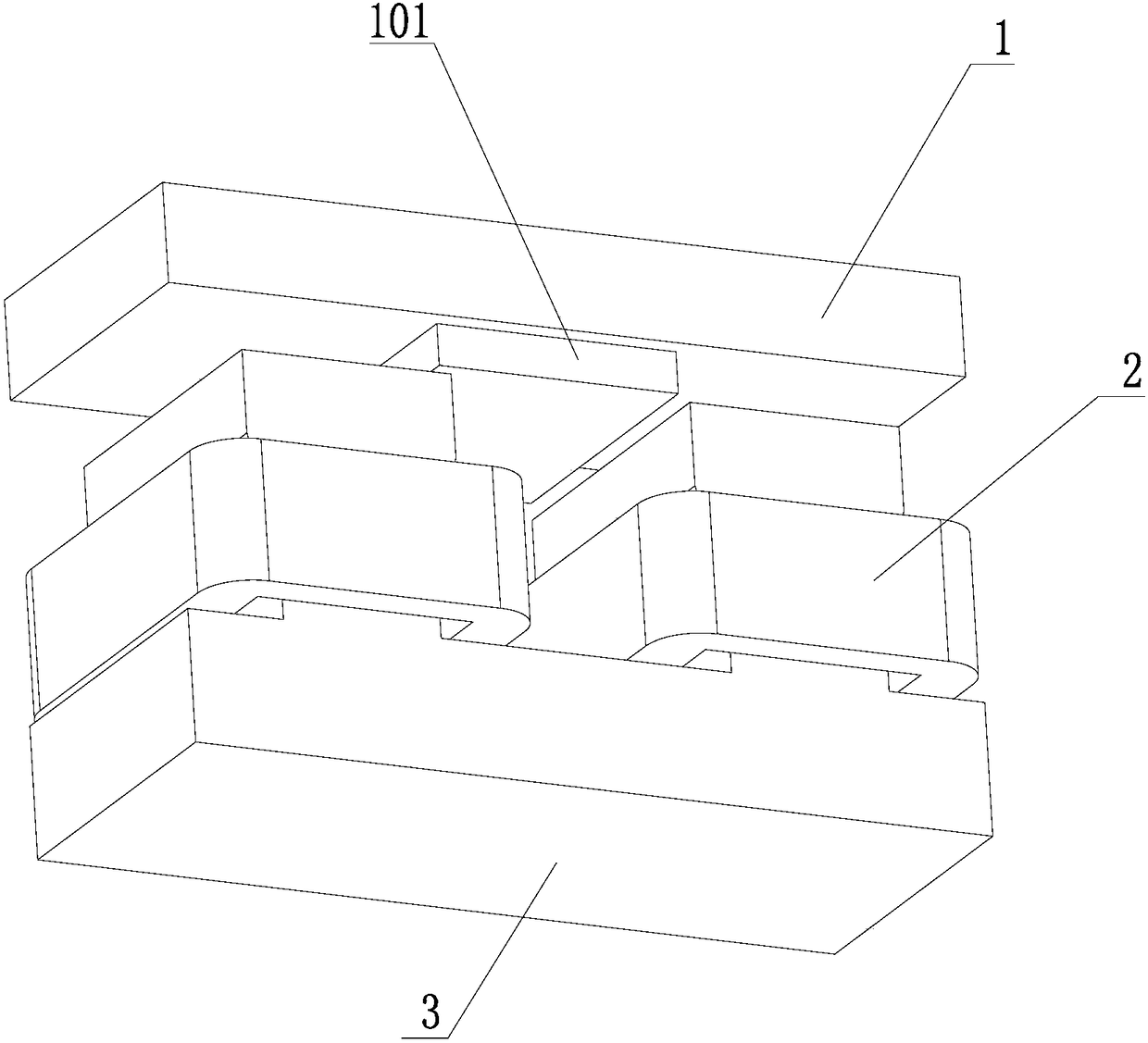

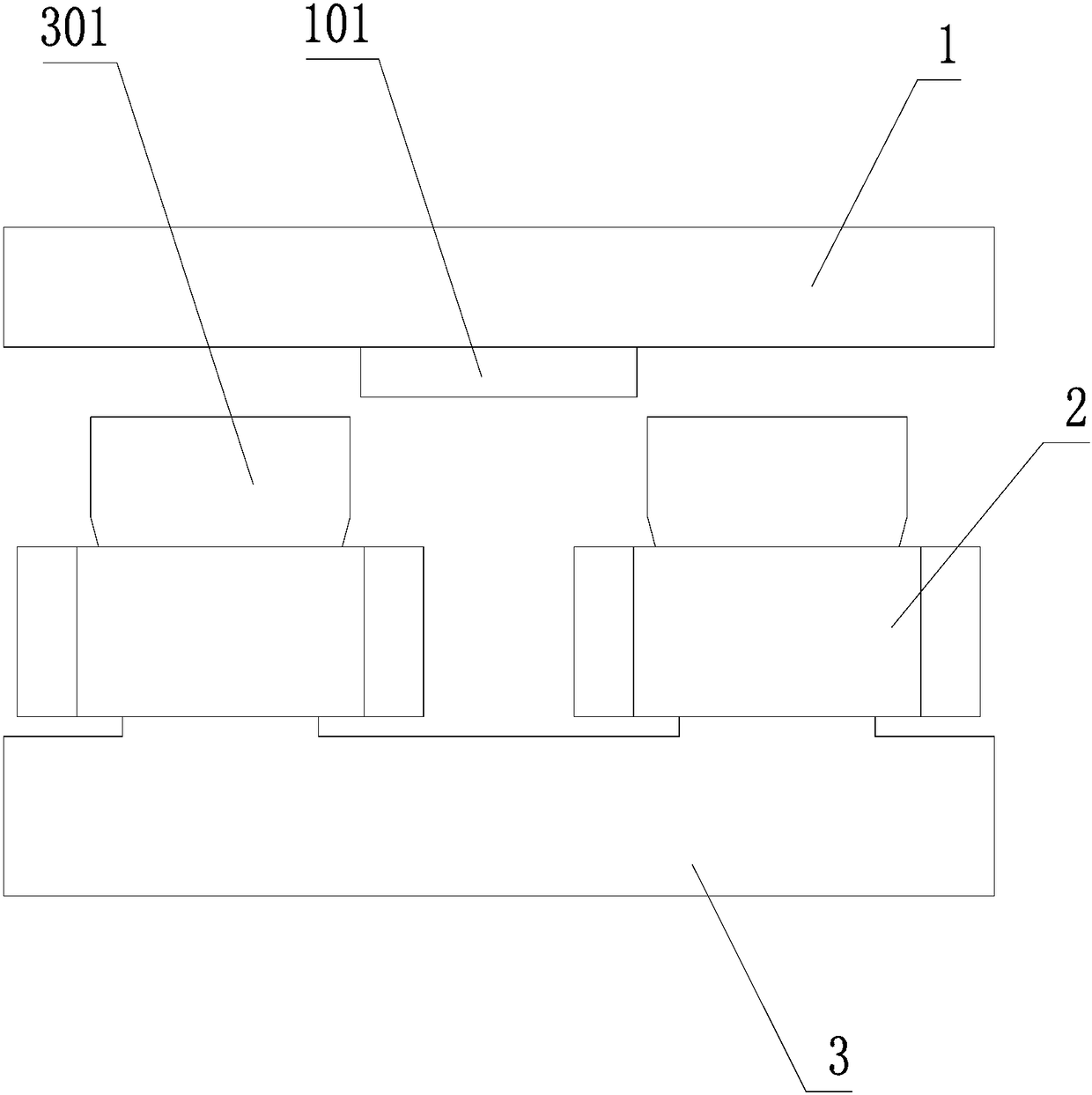

Electromagnetic system for three-phase alternating-current contactor having T-shaped armature structure

A three-phase AC and electromagnetic system technology, applied in the direction of electromagnetic relays, electromagnetic relay details, circuits, etc., can solve problems affecting the reliability of contactor action, aggravate contact arc ablation, and unfavorable contactor life, etc., to reduce The effects of contact bounce, improved electrical life, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the first embodiment, the armature is rotatably located directly above the core, and the axis of rotation of the armature is parallel to the line connecting the two bosses. When the armature and the boss are close to the minimum distance (sucked), the lower bottom surface of the armature is parallel to the boss The upper end surface of the table, and there is a gap between the two, the gap is less than 0.5mm; when released, as the distance between the two increases, the angle between the lower bottom surface of the armature and the upper end surface of the boss gradually increases; In this embodiment, the angle of rotation when the armature is released is 6.9 degrees.

Embodiment 2

[0039] In the second embodiment, the armature is slidingly fitted directly above the iron core, that is, it is installed in a straight line, and the moving direction of the iron core is perpendicular to the upper end surface of the boss; and when the armature is attracted to the boss, that is, when the distance between the two is the smallest, the armature There is a gap between the lower bottom surface of the armature and the upper end surface of the boss, and the gap is less than or equal to 0.5mm; when released, as the distance between the two increases, the lower bottom surface of the armature and the upper end surface of the boss are always parallel.

[0040] In order to avoid collision between the coil and the lower end of the armature, the minimum distance between the upper end of the coil and the bump is greater than 0mm, and there is generally a gap of 1mm-5mm. When the armature is pulled in, the distance between the two is the smallest. The minimum distance is greater tha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com