Self-elevating boarding ladder

A boarding ladder and self-elevating technology, applied in ship accessories, ships, cargo handling equipment and other directions, can solve the problems of unsafe, unreliable boarding ladders, etc., and achieve high safety, small platform space occupation, and reliability. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

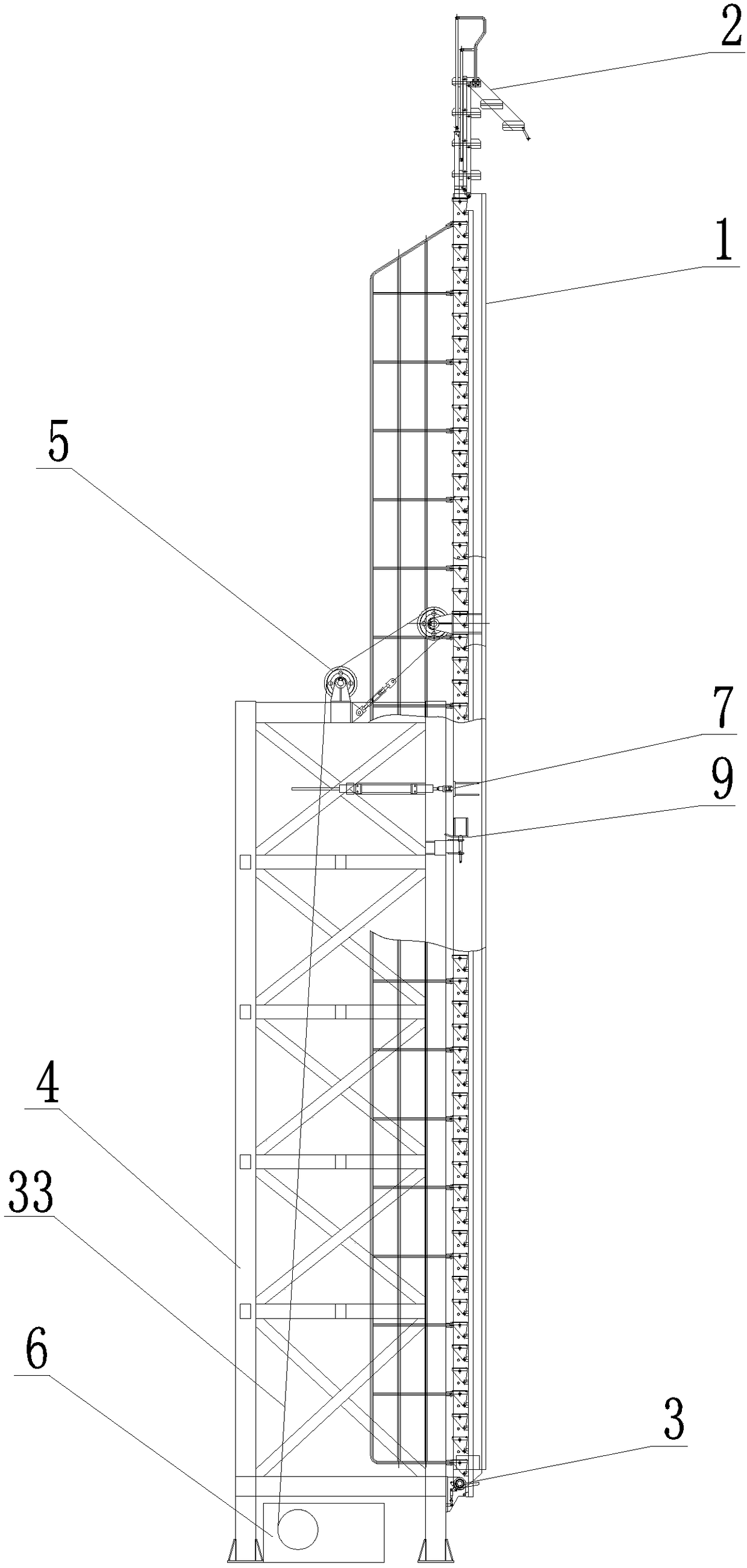

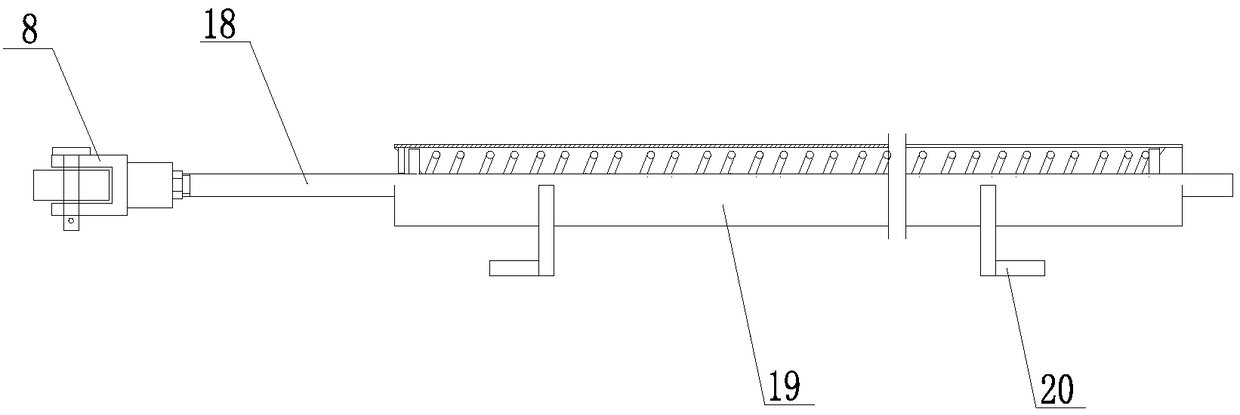

[0028] Embodiment 1 of the present invention: A self-elevating ship boarding ladder, comprising a main ladder 1, a stern ladder 2, and a tower 4. The stern ladder 2 is connected to the main ladder 1, and one end of the main ladder 1 is fixed to the main ladder by a pin assembly 3 On the tower 4, the other end is connected to a motor 6 fixed on the platform through a pulley assembly 5. A spring push rod 7 is provided on the tower 4, and the joint part 8 of the spring push rod 7 is in contact with the main ladder 1. The spring push rod A locking device 9 is arranged below 7 and the locking device 9 is fixed on the tower 4.

Embodiment 2

[0029] Embodiment 2 of the present invention: a self-elevating ship boarding ladder, comprising a main ladder 1, a stern ladder 2, and a tower 4. The stern ladder 2 is connected to the main ladder 1, and one end of the main ladder 1 is fixed to the main ladder by a pin assembly 3 On the tower 4, the other end is connected to a motor 6 fixed on the platform through a pulley assembly 5. A spring push rod 7 is provided on the tower 4, and the joint part 8 of the spring push rod 7 is in contact with the main ladder 1. The spring push rod A locking device 9 is arranged below 7 and the locking device 9 is fixed on the tower 4.

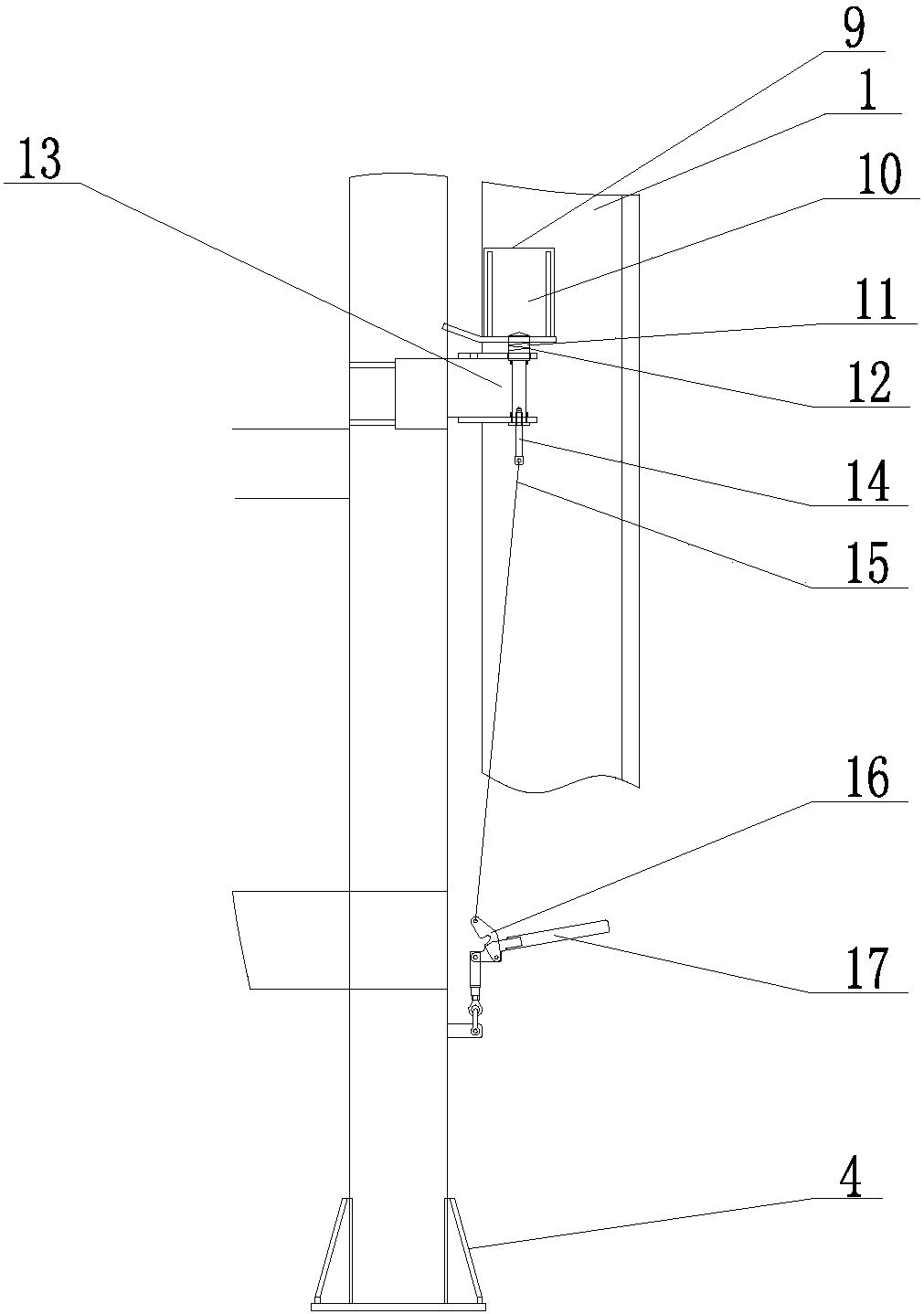

[0030] The locking device 9 includes a horizontal bumper 10, a locking pin 11, a spring 12, a lower lock box 13, a pull rod 14, a wire rope 15, a wire rope clamp 16 and a locking handle 17. The horizontal bumper 10 is connected to the locking pin 11, The locking pin 11 is connected to the lower locking box 13, and the lower locking box 13 is connected to the pu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com