Method for load monitoring of steel wire rope of mine vertical shaft hoisting system

A hoisting system and load monitoring technology, applied in elevators, transportation and packaging, etc., can solve problems such as inability to issue an alarm signal to remind the hoist driver, inconvenience in the maintenance and replacement of monitoring devices, and affecting the normal production of the hoist, achieving wide practicability. , easy operation and installation, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings.

[0022] A mine shaft hoisting system wire rope load monitoring method, comprising:

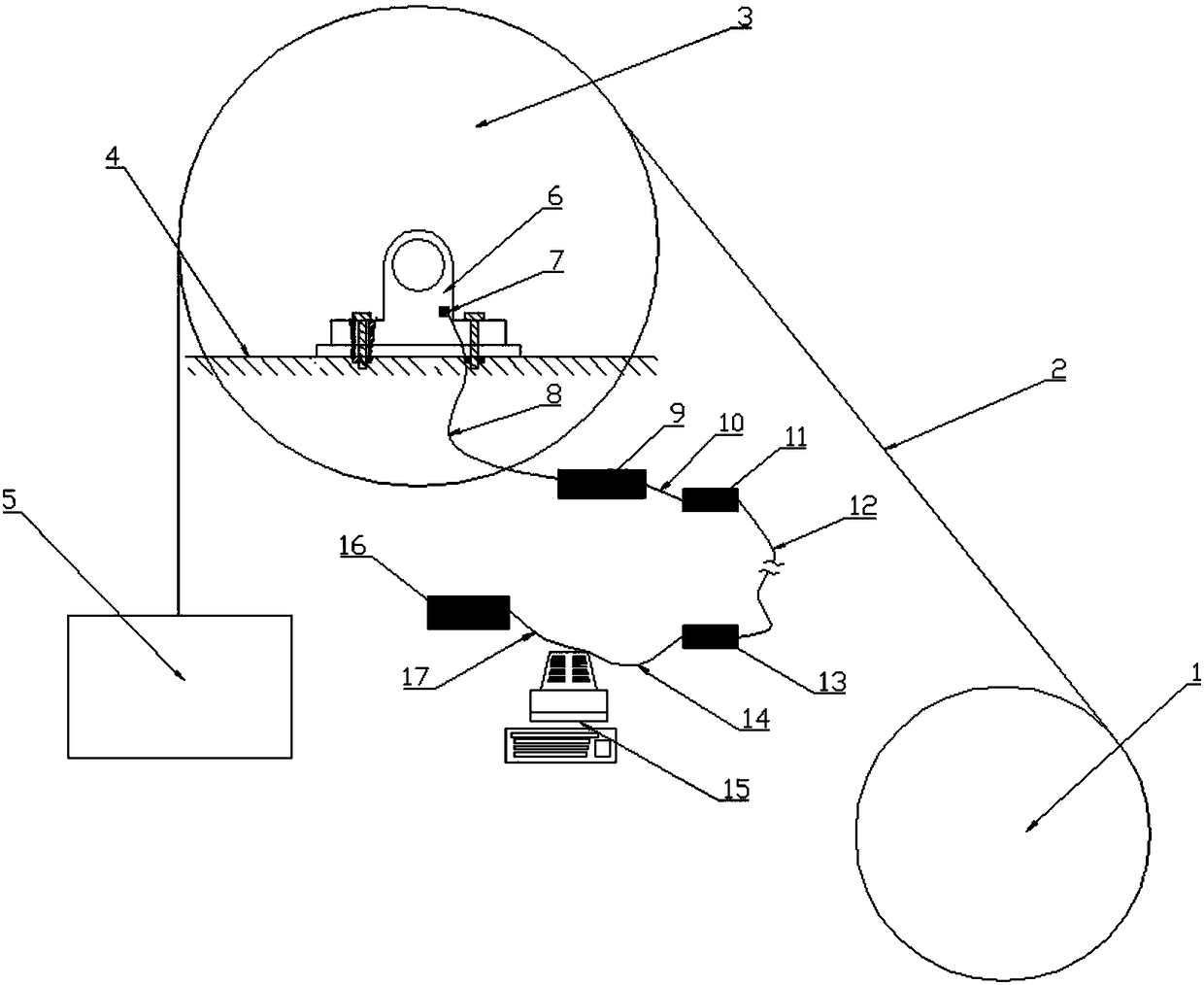

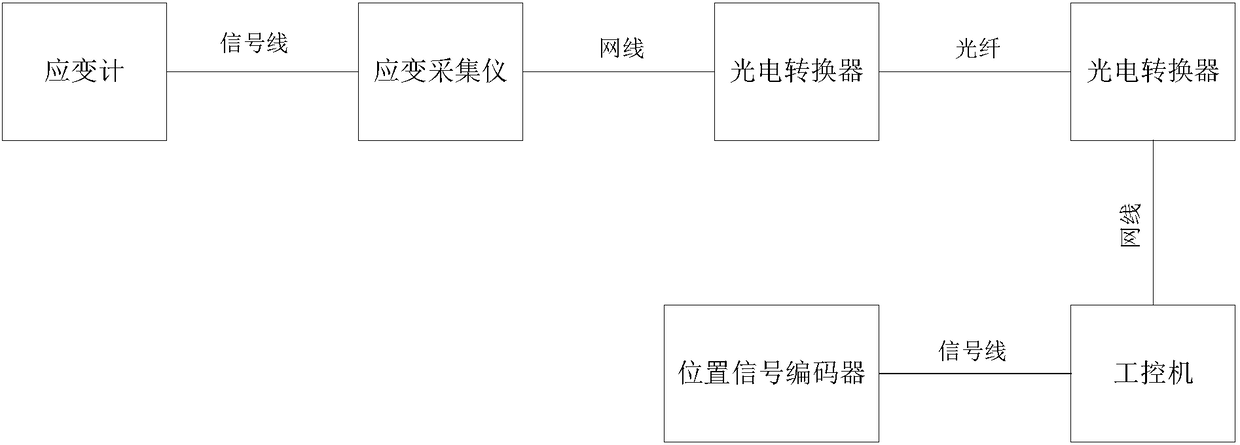

[0023] A. If figure 1 , 2 As shown, the hoisting system wire rope load monitoring system is mainly composed of a hoisting device 1, a wire rope 2, a sky wheel platform 4 for erecting a sky wheel 3 and a bearing seat 6, a lifting container 5, a strain gauge 7, a strain acquisition instrument 9, and an industrial computer 15 1. Position signal encoder 16 constitutes;

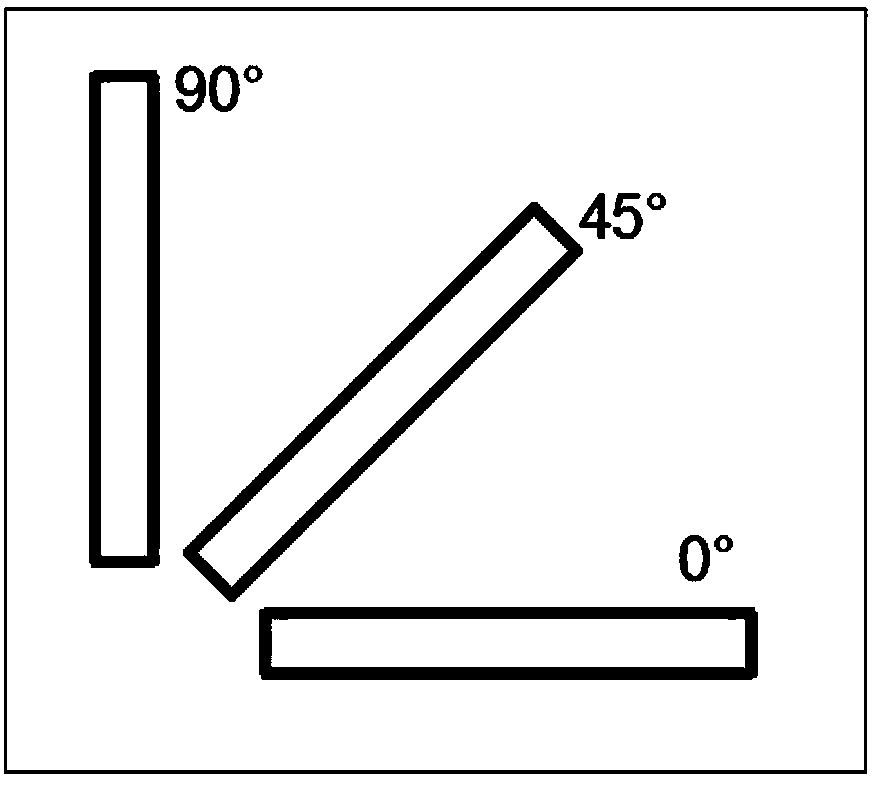

[0024] Wherein, the strain gauge 7 is composed of resistance strain gauges with three different axial (0°, 45°, 90°) sensitive grids; the strain gauge 7 is attached to the lower right corner of the bearing seat 6, and the lower right corner is the bearing seat 6 Be subjected to the maximum tension point of the steel wire rope 2, and the maximum point is the center line of the included angle of the steel wire rope 2. Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com