Steel wire rope guide device and rotary drilling rig

A technology of a guiding device and a rotary drilling rig, which is applied in the directions of rotary drilling rigs, hoisting devices, rotary drilling, etc., can solve the problem of serious friction between the wire rope and the side wall of the pulley groove, and achieve the effect of improving the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

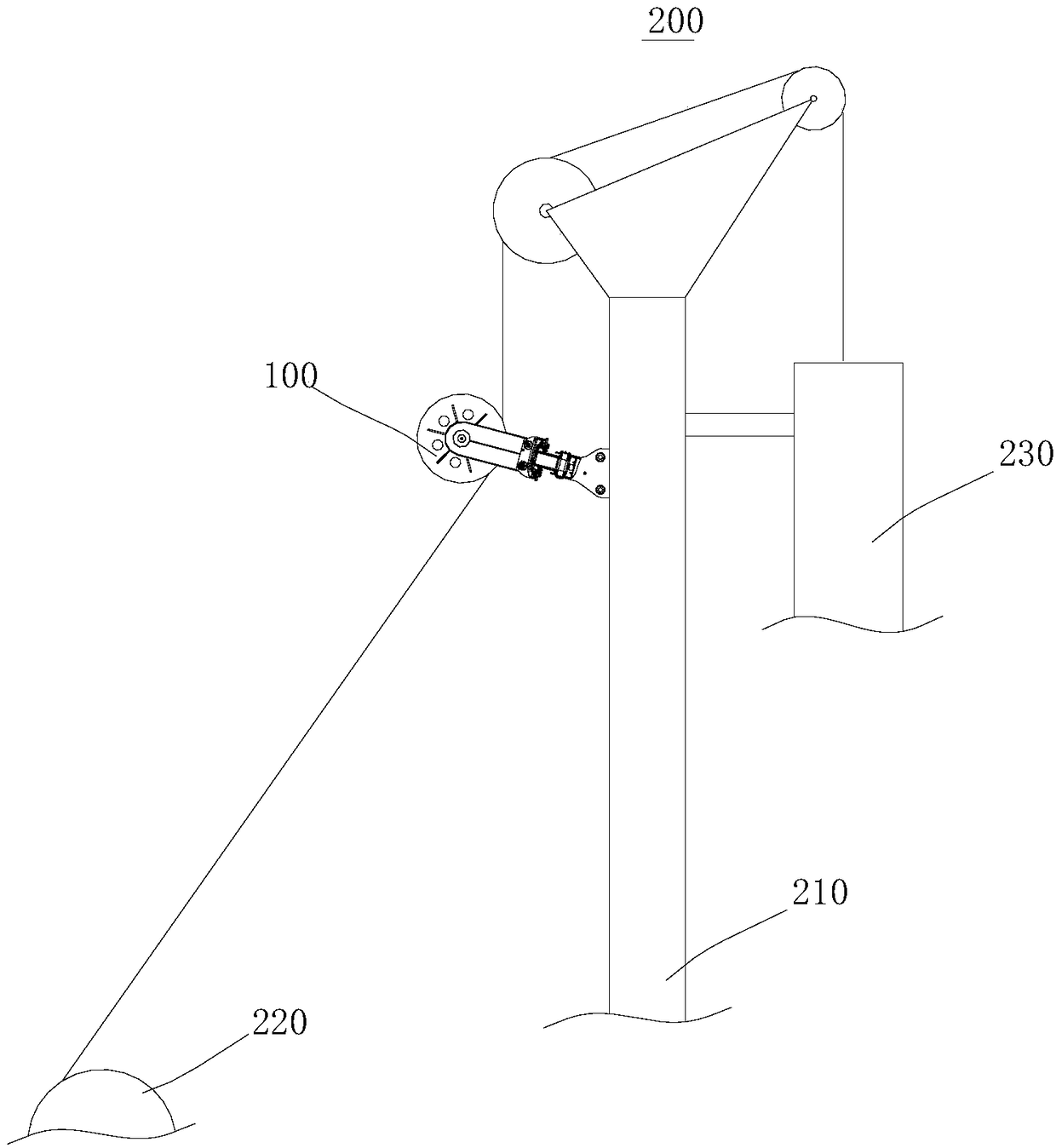

[0046] Such as figure 1 , figure 1 It is a partial structural schematic diagram of the rotary drilling rig 200 . This embodiment provides a rotary drilling rig 200, which mainly includes a chassis (not shown in the figure), a winch 220, a mast 210 and a drill rod, the winch 220 and the mast 210 are respectively connected to the chassis, and the mast 210 is A wire rope guiding device 100 is provided, one end of the wire rope is wound on the winch 220, and the other end is connected to the upper end of the drill pipe after winding around the wire rope guiding device 100.

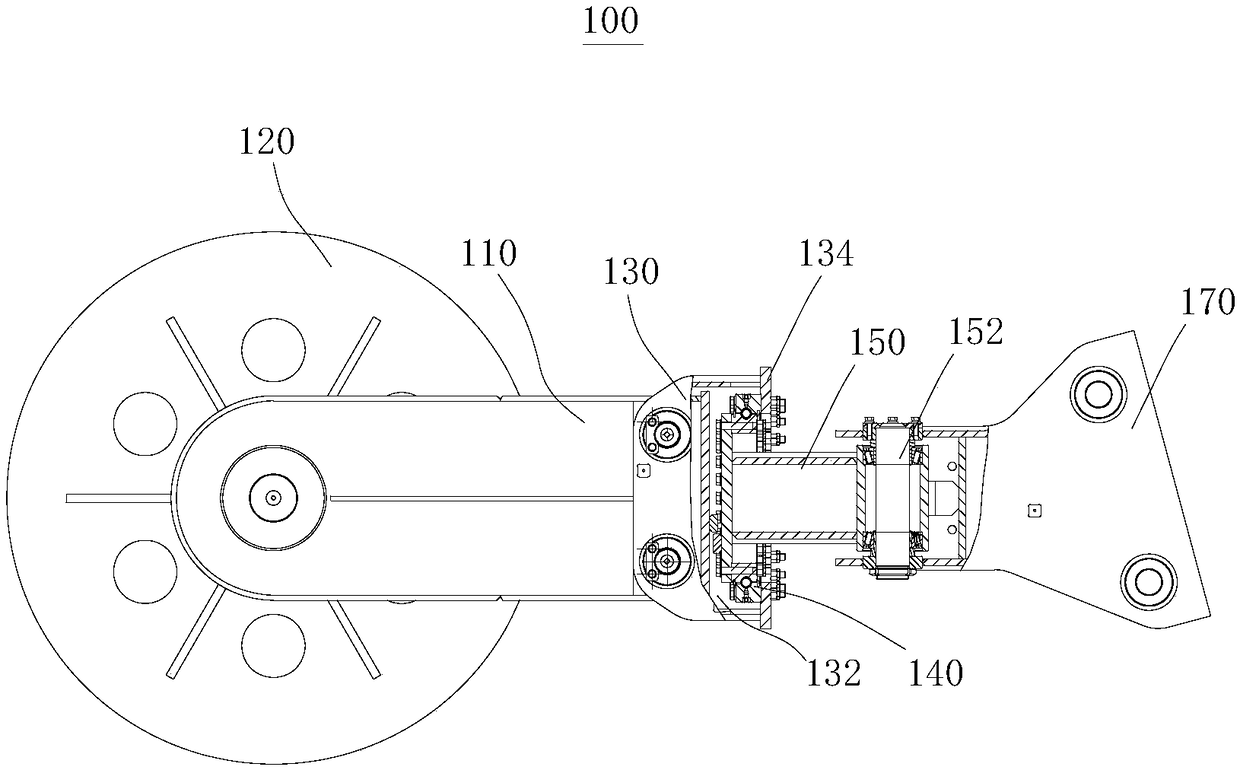

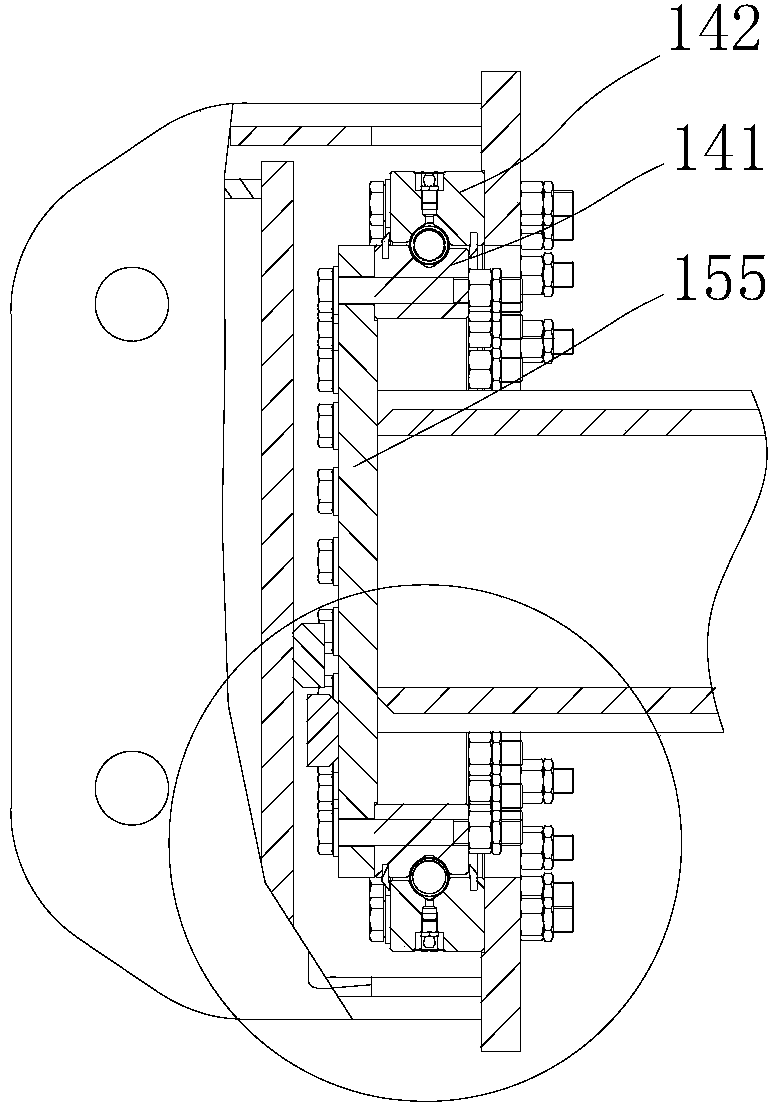

[0047] Such as figure 2 , figure 2is a structural schematic diagram of the wire rope guiding device 100 , which mainly includes a connecting frame 110 , a slewing support 140 , a swing arm 150 and a support 170 . One end of the connecting frame 110 is provided with a pulley 120, and the other end is rotatably connected with the swing arm 150 through the slewing support 140; .

[0048] Specifically, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com