Haunch supporting type energy consumption bearing brace and its construction method

An energy-consuming bracing and axillary bracing technology, applied in protective buildings/shelters, building components, earthquake-proof, etc., can solve problems such as low energy consumption capacity of prestressed tendons connecting beams and columns, low energy consumption of concrete, casualties, economic losses, etc. Achieve the effect of avoiding overall structural damage, improving earthquake resistance, and reducing economic losses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

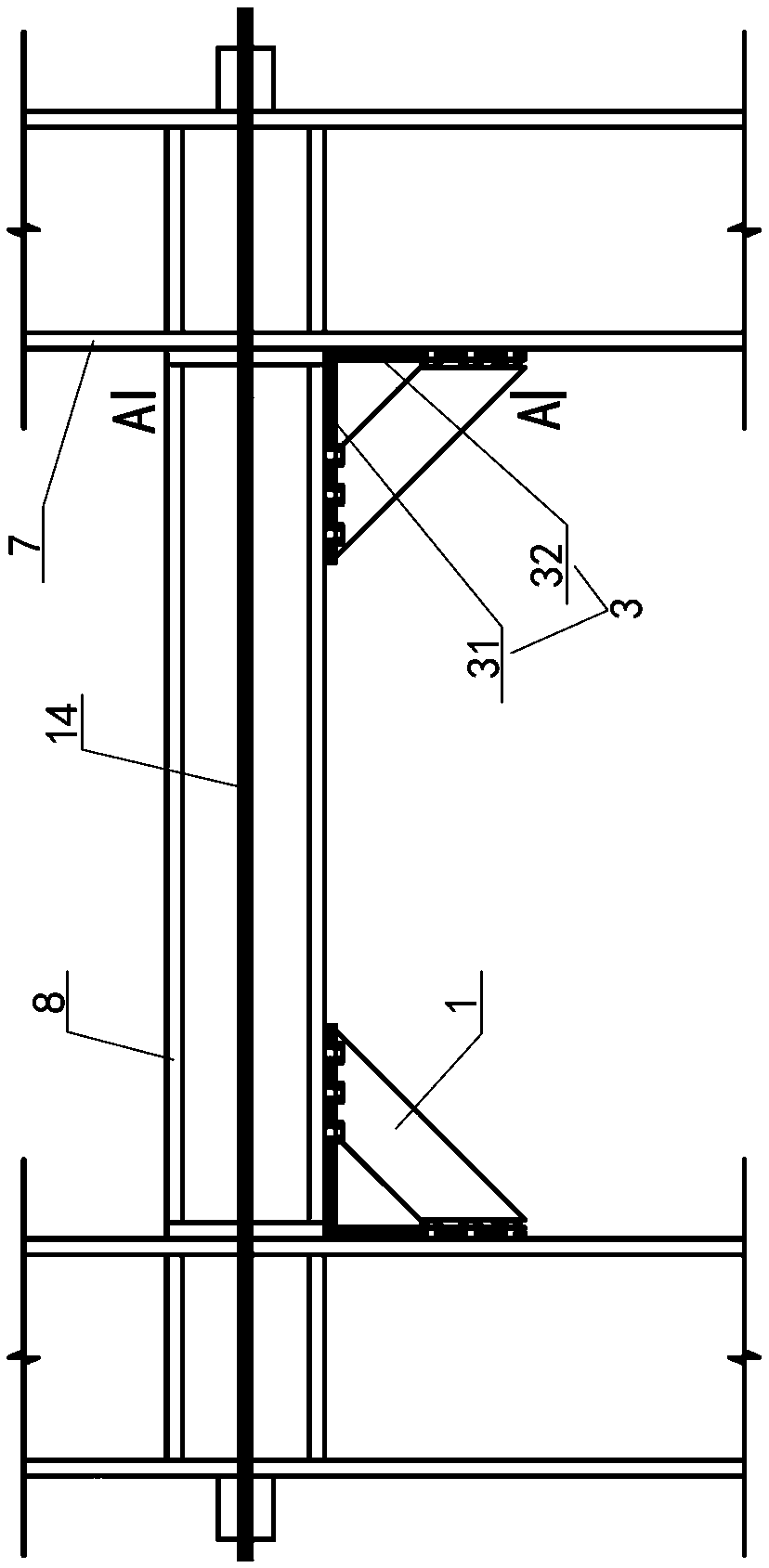

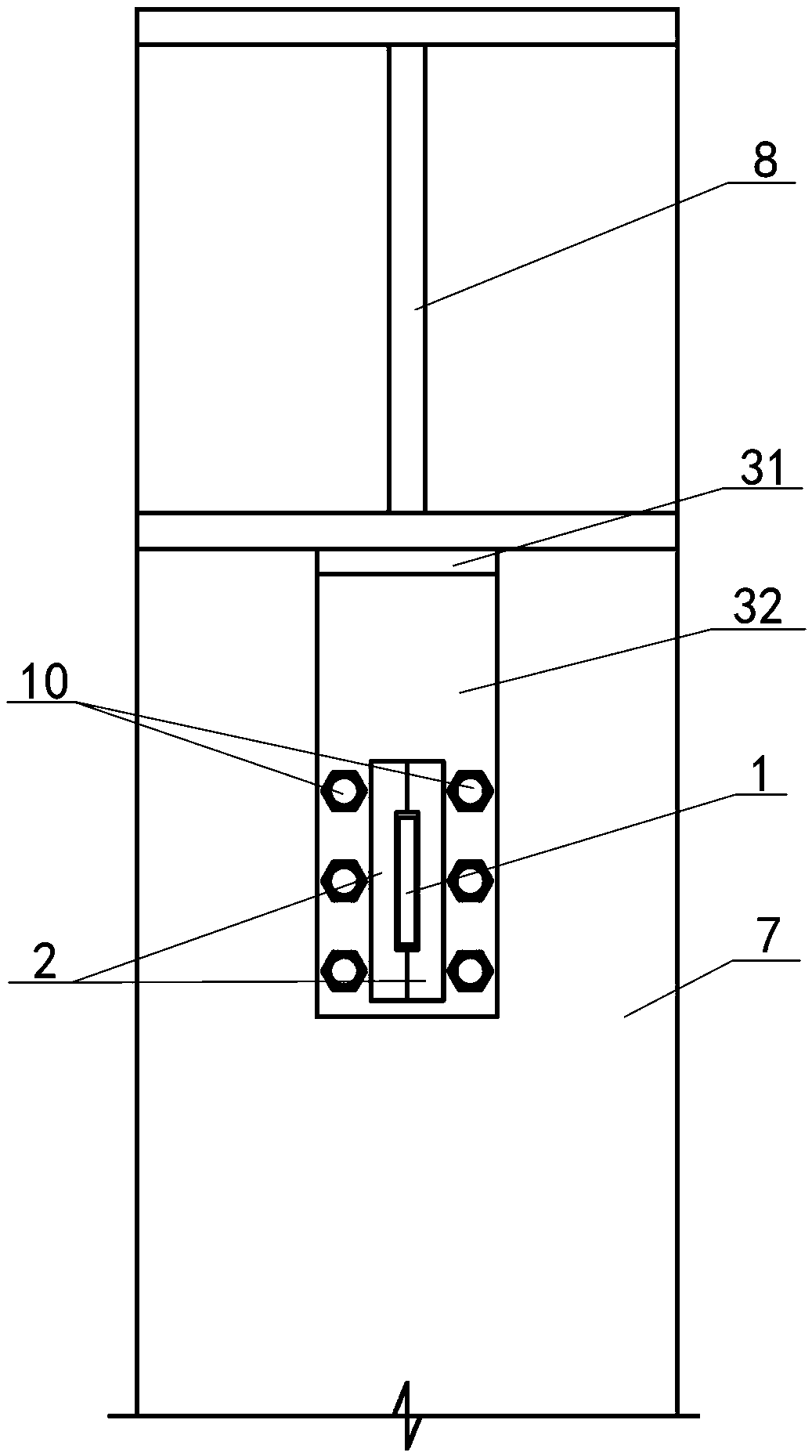

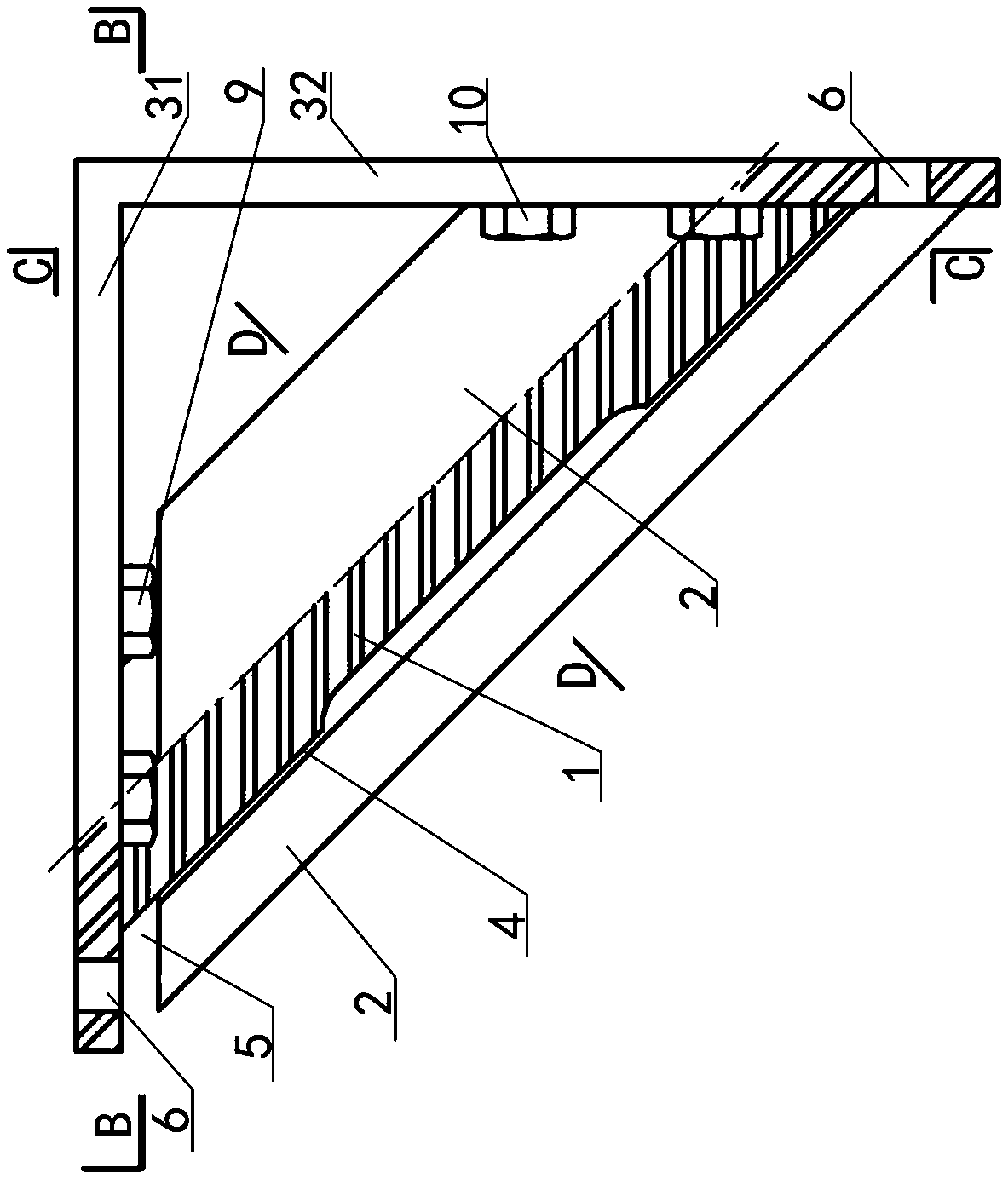

[0053] Embodiment one sees Figure 1-7 As shown, a beam-column connection structure, the beam-column is connected through prestressed tendons 14 . An armpit-type load-bearing energy-dissipating support, which is fixedly connected at the armpit of the connection node between the structural column 7 and the structural beam 8, and includes a shear support steel plate 3, an energy-dissipating strip steel plate 1 and an out-of-plane restraint steel plate sleeve 2.

[0054] The shear support steel plate 3 is centered along the width direction of the structural beam 8 at the armpit of the connection node, parallel to the plane where the connection node is located, the shear support steel plate includes a horizontal plate 31 and a vertical plate 32, and the upper surface of the horizontal plate 31 is tightly closed. Attached to the lower surface of the structural beam 8 and fixedly connected by the first connecting piece 9 , the outer surface of the riser 32 is closely attached to the...

Embodiment 2

[0070] Embodiment two see Figure 8-10 As shown, the difference from Embodiment 1 is that two armpit-type load-bearing energy-dissipating supports are arranged side by side at the armpit of the joint node, and the first connector 9 is provided with two rows, which are respectively located on all out-of-plane constrained steel plates. On the outermost two sides of the cover 2, the second connectors 10 are also provided in two rows, which are respectively located on the outermost sides of all out-of-plane restraint steel plate sets 2 .

[0071] The difference from Embodiment 1 is that the out-of-plane restraint steel plate sleeve 2 is composed of two side plates with the same outer profile, which are relatively sandwiched on both sides of the energy-dissipating strip steel plate 1 and fixedly connected. The lateral side of each side plate The cross-section is trapezoidal, and the middle part of the inner surface and along the oblique installation direction of the energy-dissipat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com