Construction method for upper cylinder of cooling tower of steel structure

A construction method and technology for steel structures, applied in towers, building types, buildings, etc., can solve the problem of difficult installation of large-diameter cylinders, and achieve the effects of high construction efficiency and reliable installation and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

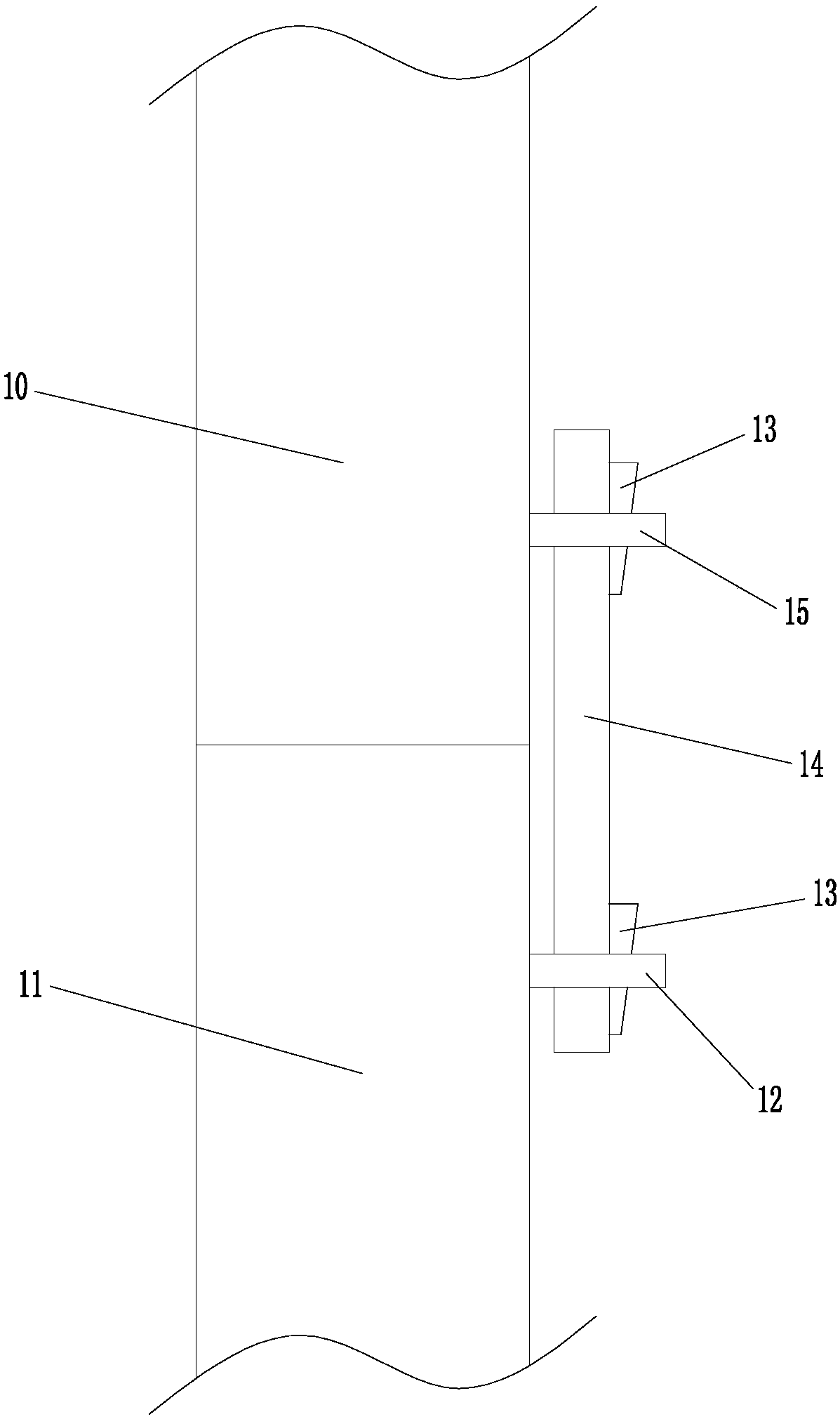

[0017] Below in conjunction with accompanying drawing and specific embodiment, the construction method of steel structure intercooling tower top cylinder of the present invention is described in further detail:

[0018] Such as figure 1 Shown, in this specific embodiment, the construction method of steel structure cooling tower top cylinder of the present invention, comprises the steps:

[0019] 1) Make a tripod, which is surrounded by a steel structure beam and two steel structure inclined beams;

[0020] 2) Install the upper lock plate 12 at both ends of the beam, install the lower lock plate 15 at the intersection of the two oblique beams, and have through holes on the upper lock plate 12 and the lower lock plate 15;

[0021] 3) Carry out quality inspection on a number of completed tripods, and transport them to the cavity surrounded by the lower cone section after passing the test;

[0022] 4) Use a tower crane to hoist the pre-installed tripod 10 upside down to the inst...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com