Connecting joint for pressure-resisting body and framework of deep-sea platform

A technology for connecting joints and pressure-resistant bodies, which is applied to the connection of rods, connecting components, and mechanical equipment. It can solve the problems of increased structural stress at the connection points, poor quality control, and few related materials, and achieves simple installation and operation. Dispersed welding risks and low worker requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

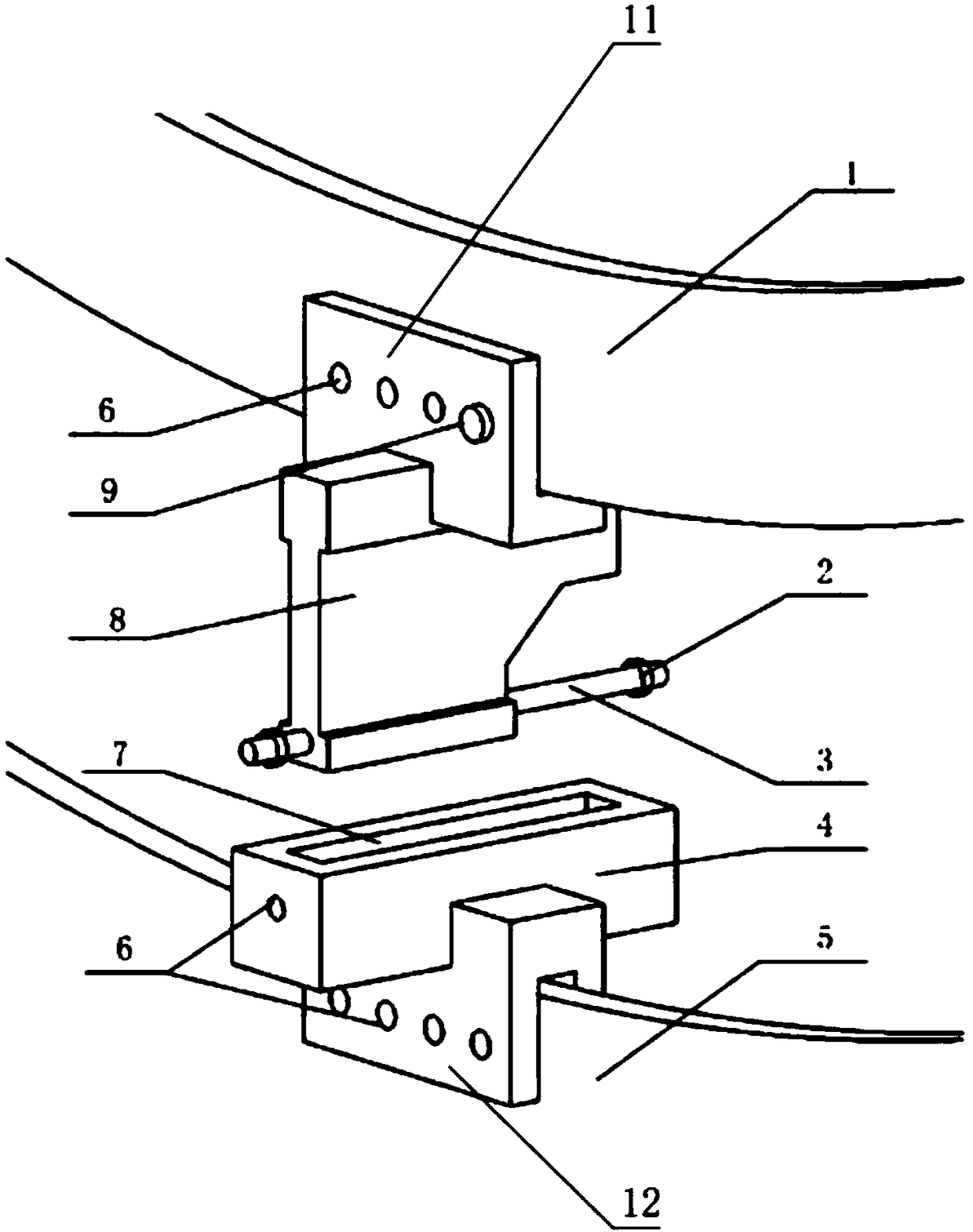

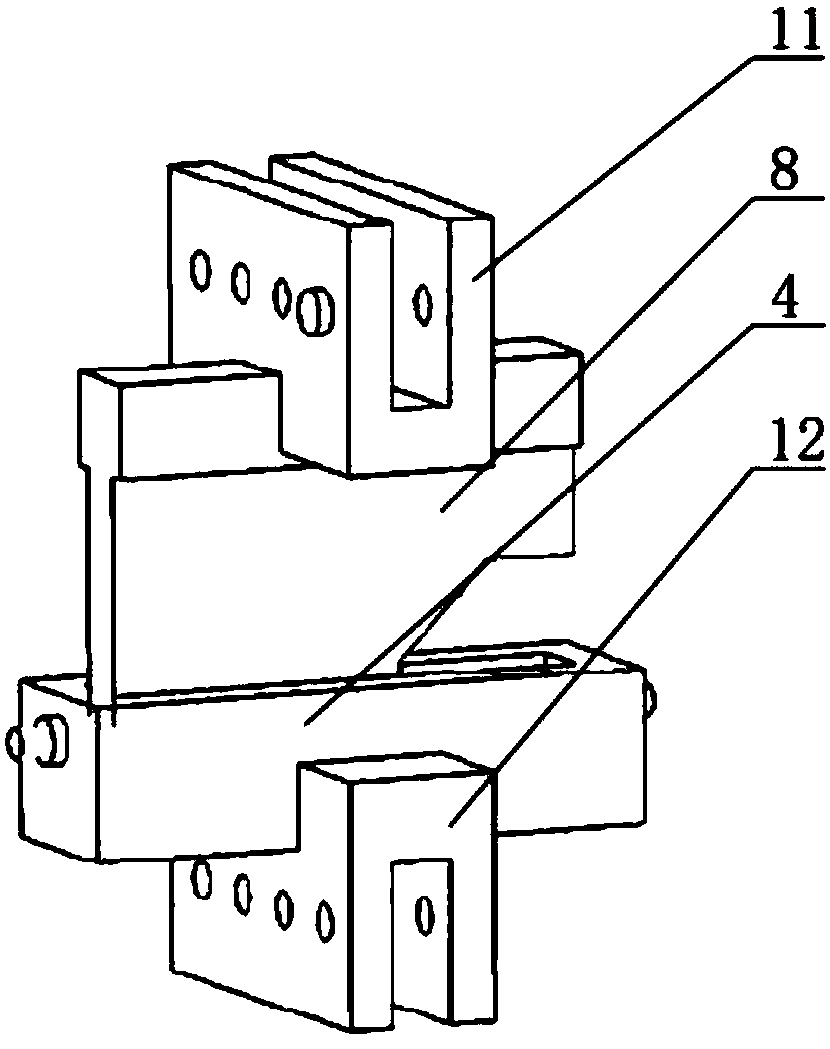

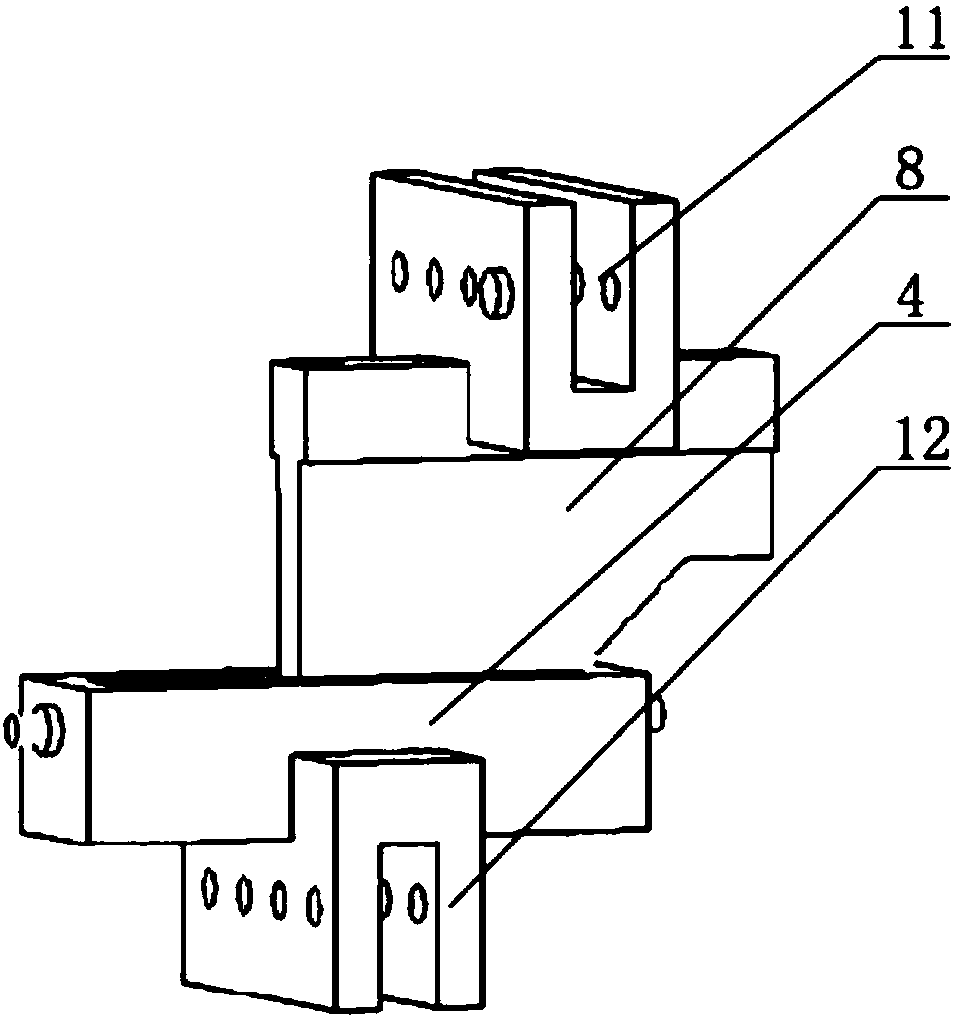

[0036] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

[0037] like Figure 1-Figure 8 As shown, the connection joint between the deep-sea platform pressure body and the frame of this embodiment includes a frame 5, and a plurality of pressure shells 18 are installed inside the frame 5, and each pressure shell 18 is connected to the frame 5 through displacement compensation. Joint 10, movable joint 17 and fixed joint 20 are connected.

[0038] The frame 5 is provided with a front connection frame 21, two middle connection frames 22 and a rear connection frame 23, one end of the fixed joint 20 is installed on one of the middle connection frames 22, and the displacement compensation joint 10 is installed on the front connection frame 21 at the most two ends And on the back connection frame 23, movable joint 17 is installed on another middle connection frame 22.

[0039] The structure of the disp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com