Method of acquiring metal surface oxide layer thickness

A technology for oxide layer thickness and metal surface, applied in the field of obtaining metal surface oxide layer thickness, can solve the problems of long time, complex metallographic detection, high microscope price, etc., and achieve the effect of simple and easy operation and low measurement cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

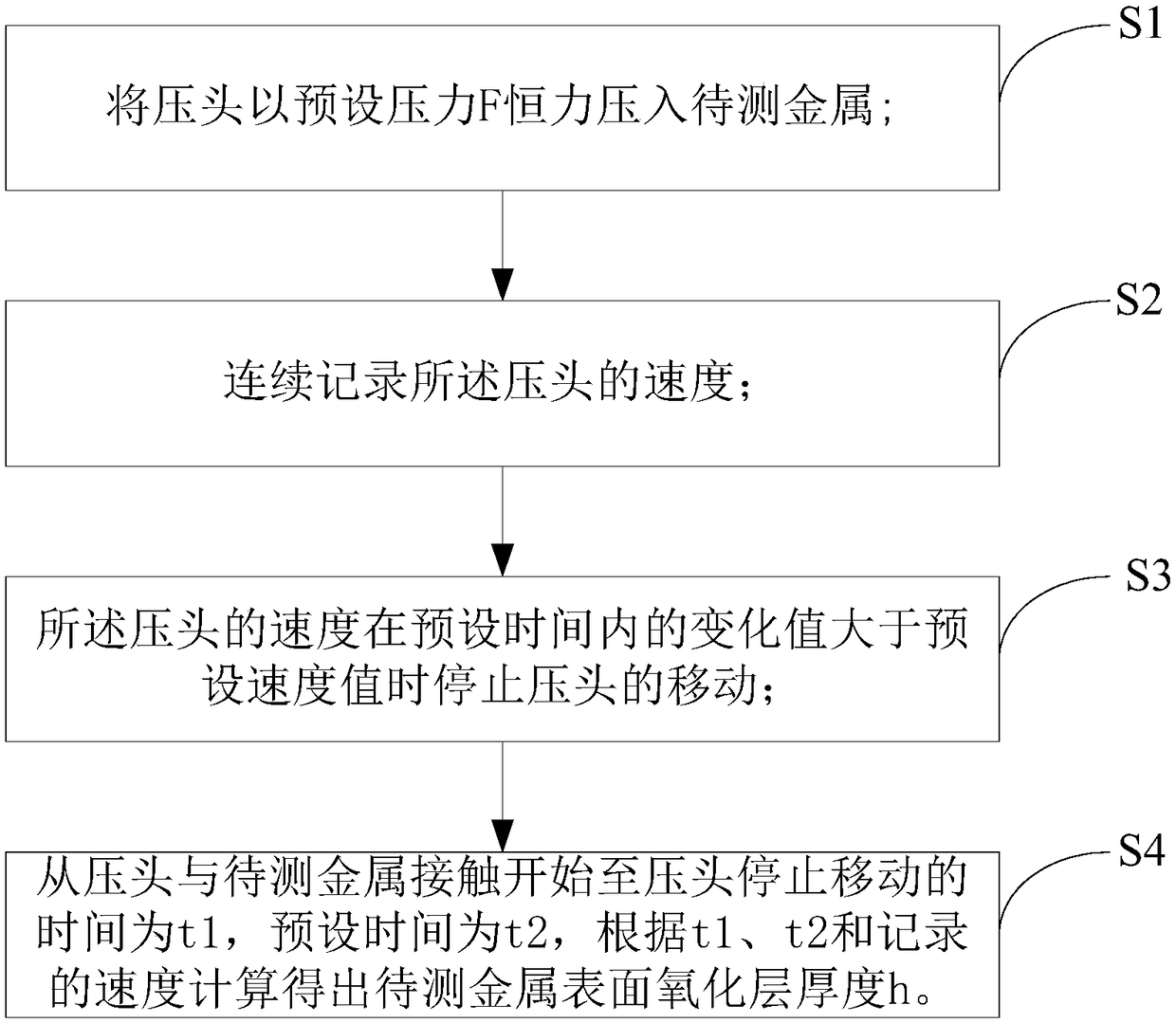

[0035] The object of the present invention is to provide a method for obtaining the thickness of the oxide layer on the metal surface, which can quickly and conveniently measure the oxide layer on the metal surface.

[0036] The inventors have found through research that the hardness of the oxide layer on the metal surface is very different from that of the metal substrate. Taking steel as an example, since the composition of the oxide layer on the steel surface is Fe 3 o 4 , Fe 2 o 3 and FeO, the matrix composition of steel is Fe 3 C and other carbides have different densities and hardness differences between the oxide layer and the substrate. The present invention has developed a method for measuring the thickness of the oxide layer using the hardness gap between the metal substrate and the oxide layer.

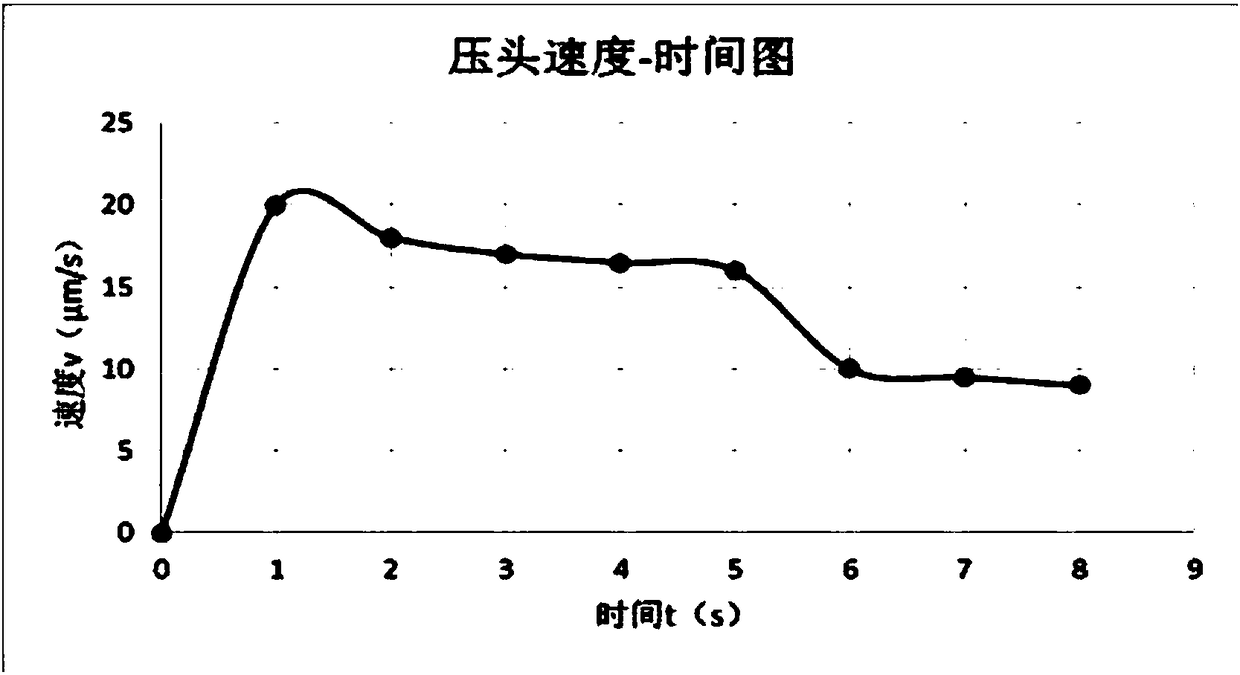

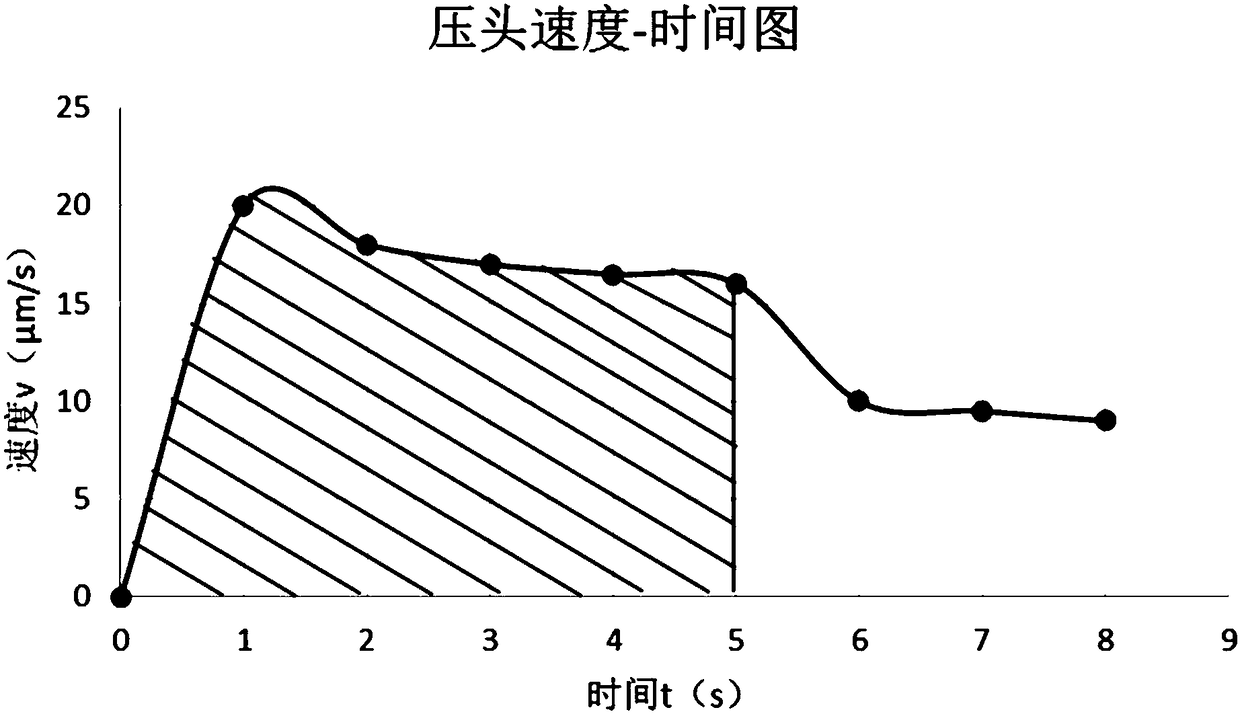

[0037] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com