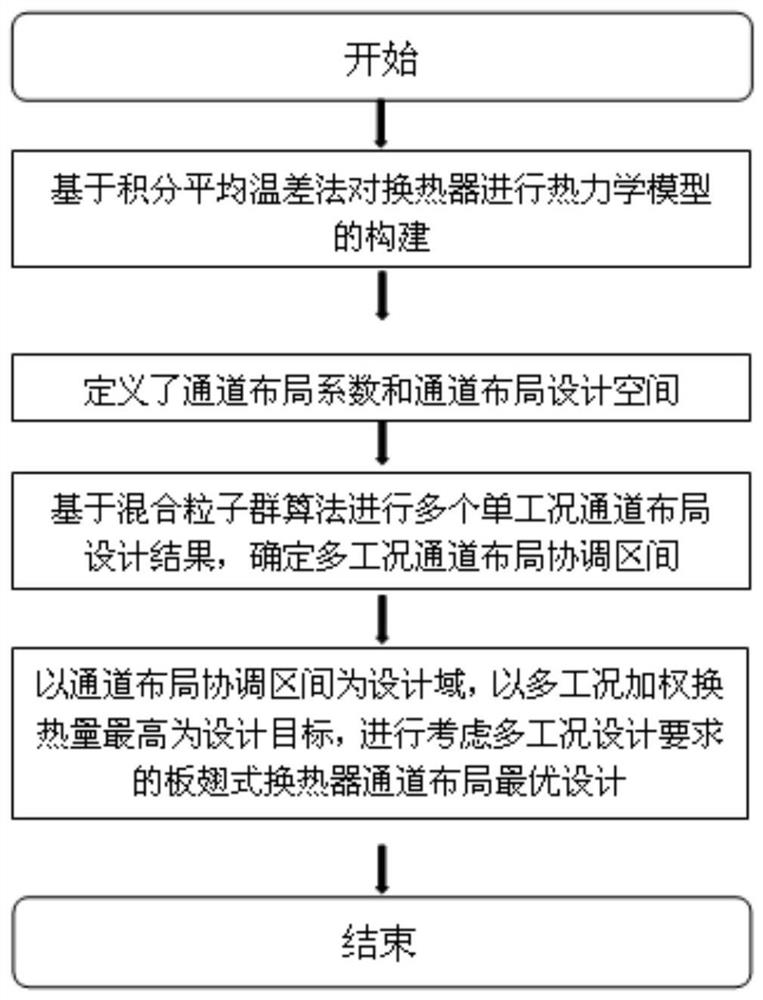

A design method of channel layout of plate-fin heat exchanger under multiple working conditions based on integral average temperature difference method

A plate-fin heat exchanger and layout design technology, which is applied in the field of channel layout design of super-large plate-fin heat exchangers under multi-working conditions, can solve the problem of inapplicable heat exchanger channel layout design, complex operating conditions, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

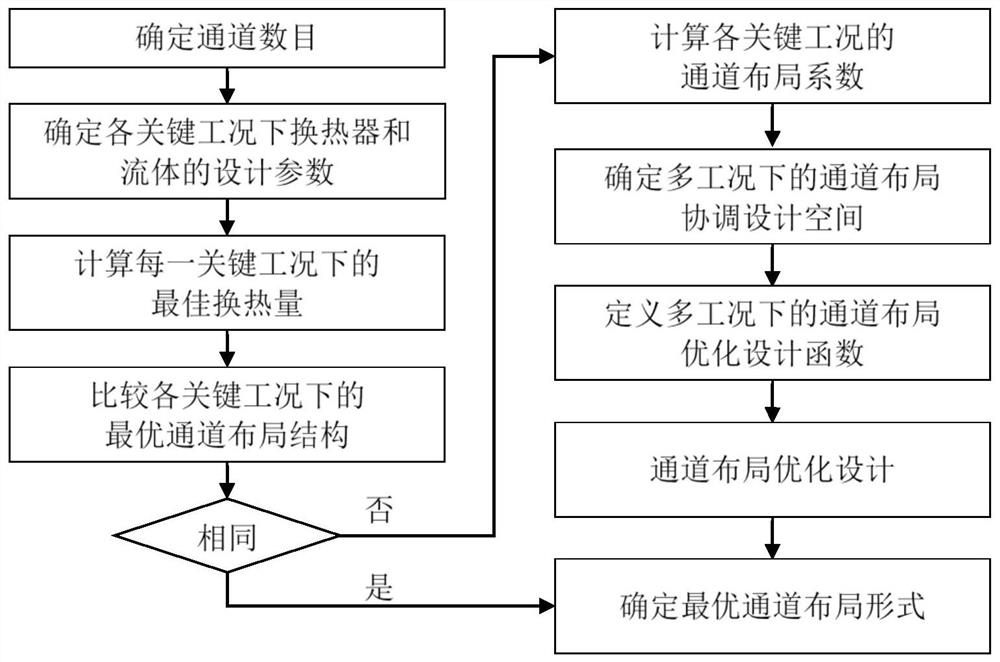

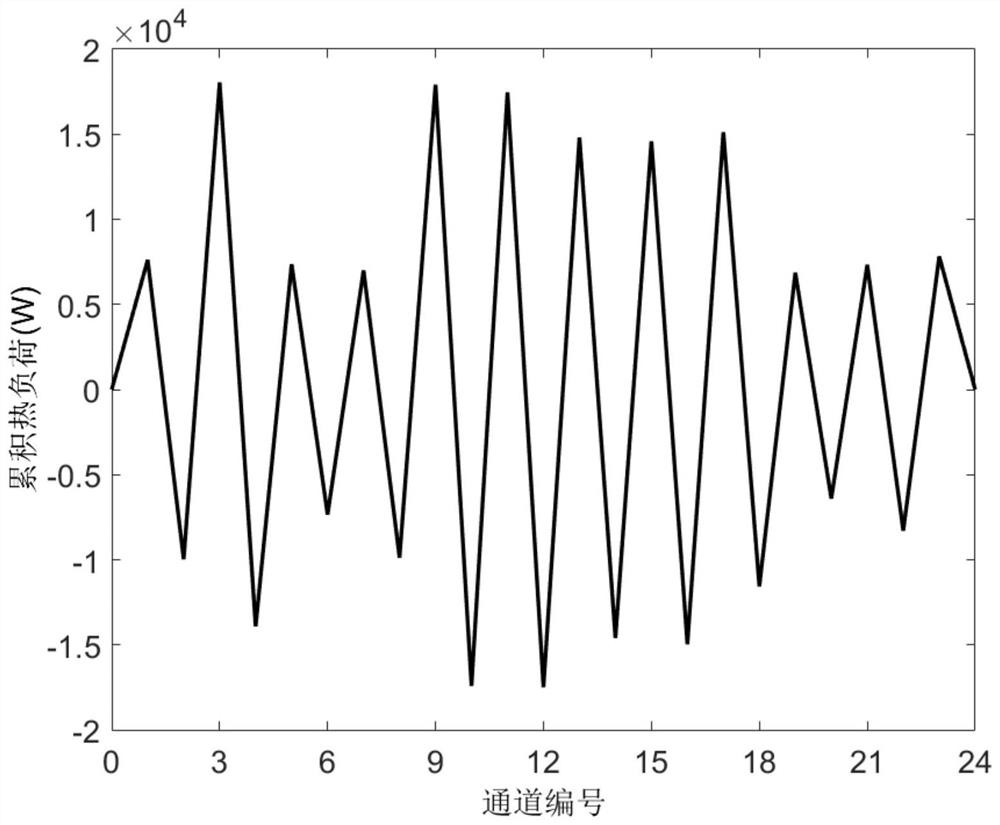

[0093] Carry out a channel layout design of a 24-stream heat exchanger including 3 streams of A, B, C, I, J, K, L and M under complex working conditions, and design the fluid and fins used in the 24-stream heat exchanger The parameters are shown in Table 1:

[0094] Table 1 Fluid and fin design parameters used in 24-stream heat exchanger

[0095]

[0096] The material of the fins used is aluminum, and the heat transfer coefficient is 0.19158kW / m·K. The hot fluid flows in the direction of increasing x, and the cold fluid flows in the direction of decreasing x. Therefore, the flow directions of the hot and cold fluids are denoted by 1 and -1, respectively. The total length and width of the heat exchanger are 1 m and 0.5 m, respectively.

[0097] The channel layout design of 24 stream heat exchangers (including streams A, B, C, F, G, H and N) under consideration of 80%-110% variable operating conditions is carried out. The channel layout results of single working conditions...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com