A transmission connection structure for high current DC contactor

A DC contactor, transmission connection technology, applied in relays, electromagnetic relays, electromagnetic relay details and other directions, can solve the problems of increased difficulty in after-sales service, increased contactor opening distance, increased contactor volume, etc., to improve transmission efficiency. , the effect of simplifying the number and structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

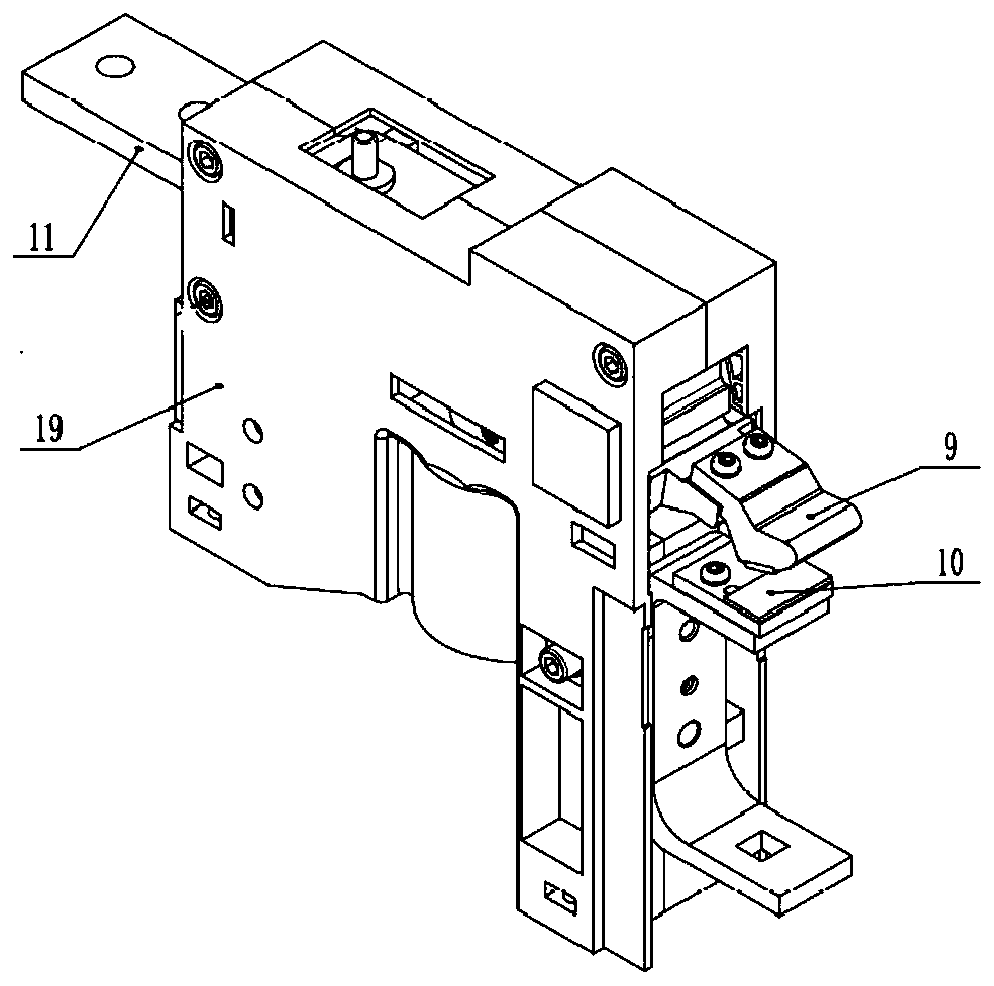

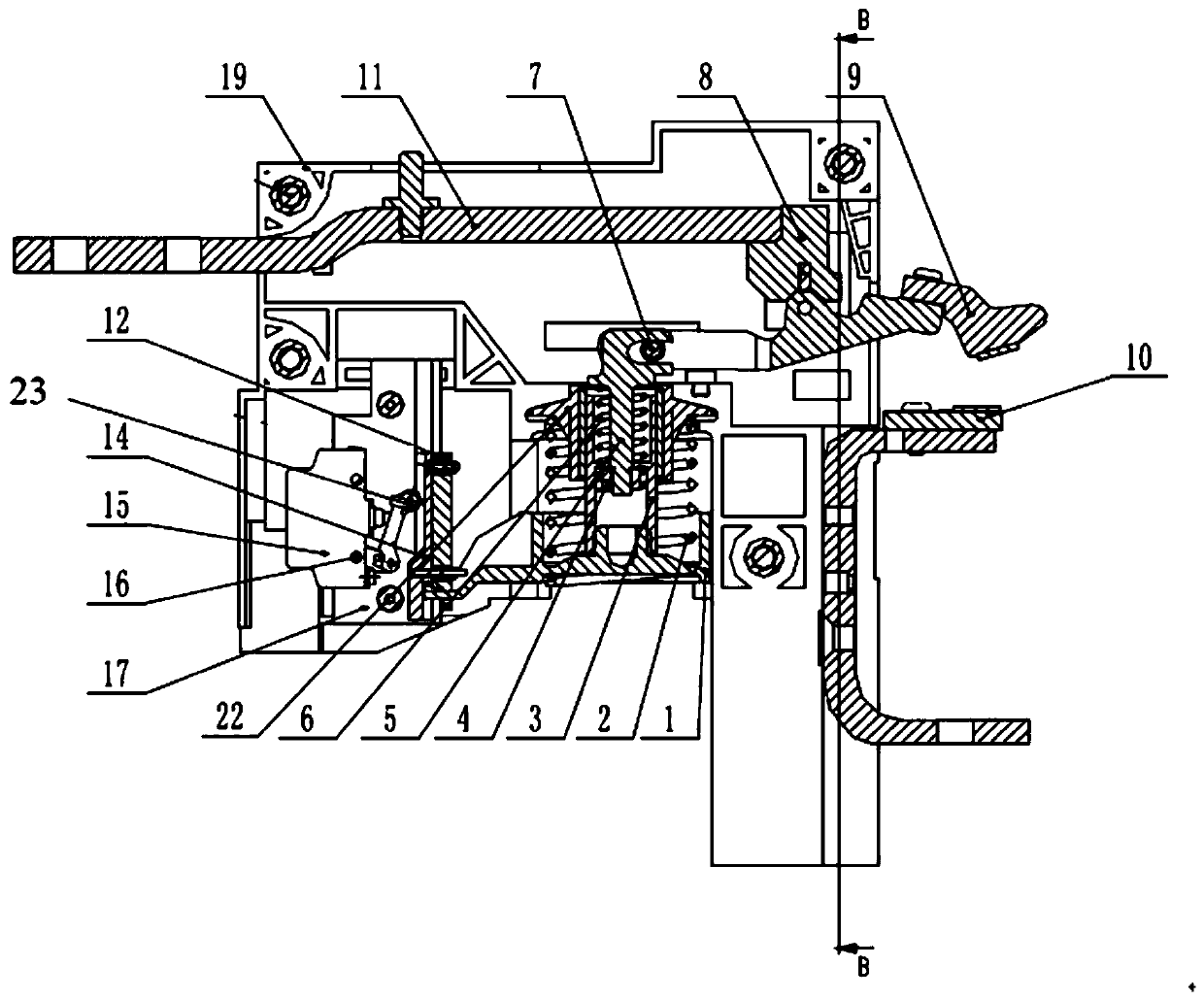

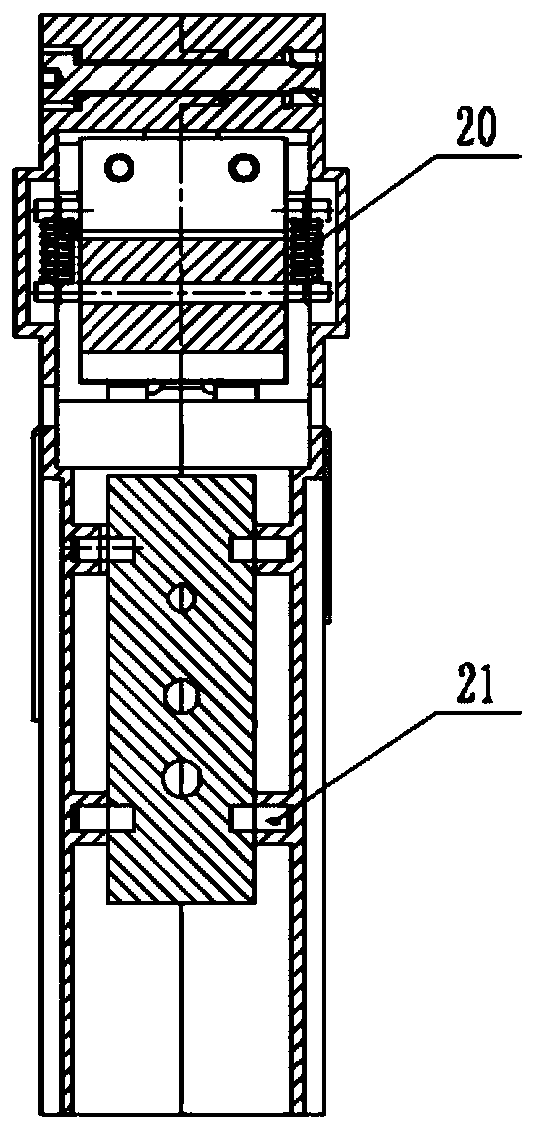

[0026] Such as Figures 1 to 4 As shown, a transmission connection structure for high-current DC contactor, which transmits the action of the electromagnet to the control switch, converts it into a control signal and feeds it back to the remote locomotive control system, which specifically includes a spring system, a support seat 8, a dynamic The contact 9, the static contact 10, the conductive copper bar 11, the action mechanism of the micro switch and the shell 19; the shell 19 is made of SMC composite material, and the SMC composite material is a kind of glass fiber reinforced plastic. The main raw materials are composed of GF (special yarn), MD (filler) and various auxiliary agents. It first appeared in Europe in the early 1960s, and around 1965, the United States and Japan successively developed this craft. In the late 1980s, our country introduced foreign advanced SMC production lines and production techniques. It has good sealing and waterproof performance, anti-corro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com