Pixel structure and OLED display panel containing pixel structure

A pixel structure and pixel technology, applied in the field of OLED display panels, can solve the problems of non-full-color display and distortion of display effects, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

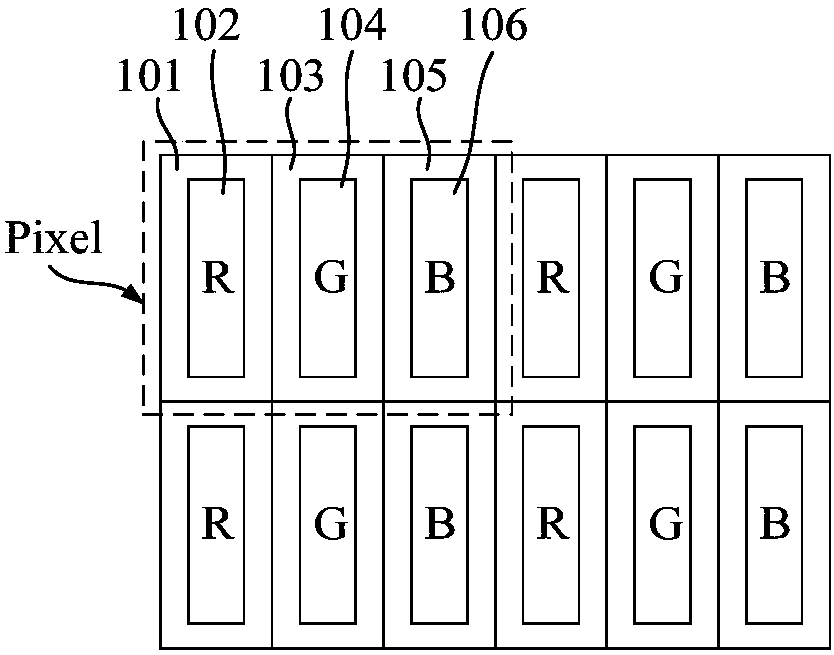

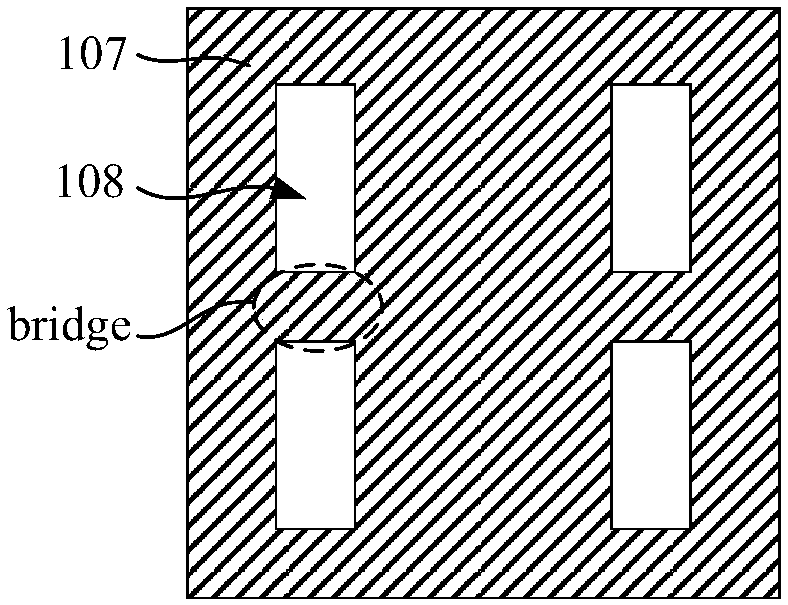

Embodiment 1

[0030] Figure 4 It is a schematic diagram of pixel arrangement of an OLED display panel in Embodiment 1 of the present invention. Here, the X direction is referred to as the row direction (horizontal direction), and the Y direction is referred to as the column direction (vertical direction). For simplicity, only a part of the OLED display panel is shown in the drawings, and the number of pixels in an actual product is not limited to this, and the number of pixel units can be changed accordingly according to actual display requirements. The first row, the second row, the first column, the second column, etc. mentioned in the present invention are all used to illustrate the present invention and take the reference standard shown in the figure, and do not refer to the rows and columns in the actual product.

[0031] Such as Figure 4 As shown, the pixel structure of the OLED display panel includes a plurality of pixel units arranged in an array, and each pixel unit includes a ...

Embodiment 2

[0040] Figure 5 It is a schematic diagram of the pixel arrangement of the OLED display panel in the second embodiment of the present invention. Such as Figure 5 As shown, each pixel unit includes a first sub-pixel 301, a second sub-pixel 303 and a third sub-pixel 305, the first sub-pixel 301 and the second sub-pixel 303 are arranged in a column, and the third sub-pixel The pixels 305 are arranged in another column, and the arrangement structure of all pixel units in the same row is the same, and the arrangement structure of each pixel unit flipped along the row direction (left and right flipped) is the same as that of the adjacent pixel units in the same column. The cloth structure is the same. For example, the pixel unit (1, 1) in the first row and the first column is flipped 180 degrees along the row direction, and the arrangement structure is the same as the adjacent pixel unit in the same column, that is, the pixel unit (2, 1 in the first column of the second row) ) h...

Embodiment 3

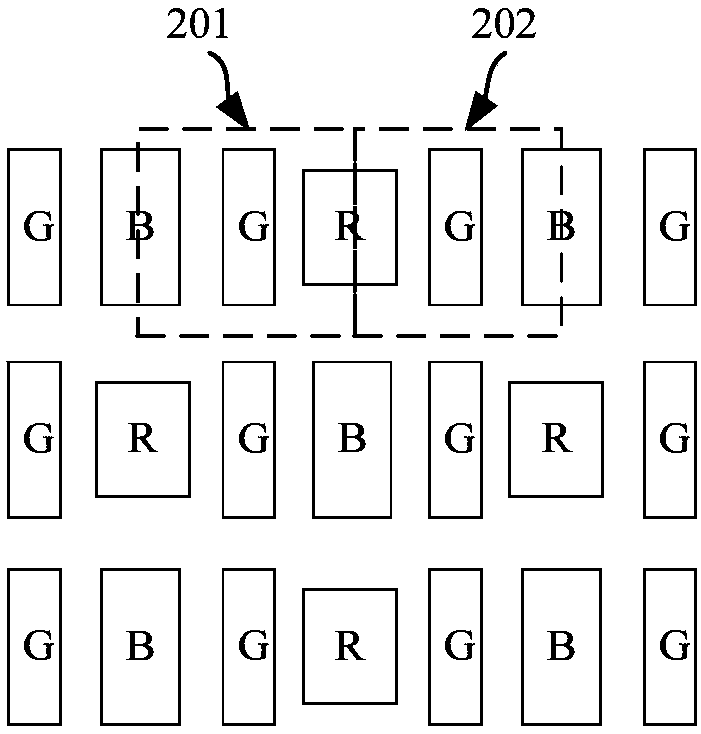

[0043] Figure 6 It is a schematic diagram of pixel arrangement of the OLED display panel in the third embodiment of the present invention. Such as Figure 6As shown, the difference between this embodiment and Embodiment 1 is that the first sub-pixels 301 of all pixel units in the same row are not arranged in a straight line, and at the same time, the second sub-pixels 303 of all pixel units in the same row are not Instead, the first sub-pixels 301 and the second sub-pixels 303 of all pixel units in the same row are alternately arranged on a straight line. For example, the first sub-pixel 301 of the pixel unit (1, 1) in the first row and the first column, the second sub-pixel 303 of the pixel unit (1, 2) in the first row and the second column, the first row and the third column The first sub-pixels 301 of the pixel unit (1, 3) are sequentially arranged on a straight line.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com