Preparation method of iron molybdenum based catalyst for preparing formaldehyde by methanol oxidation and application

A catalyst and oxidation technology, applied in the preparation of organic compounds, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problems of short service life, cumbersome preparation process steps, and complex catalyst composition etc. to achieve the effects of good stability, simple operation, and controllable distribution of active sites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

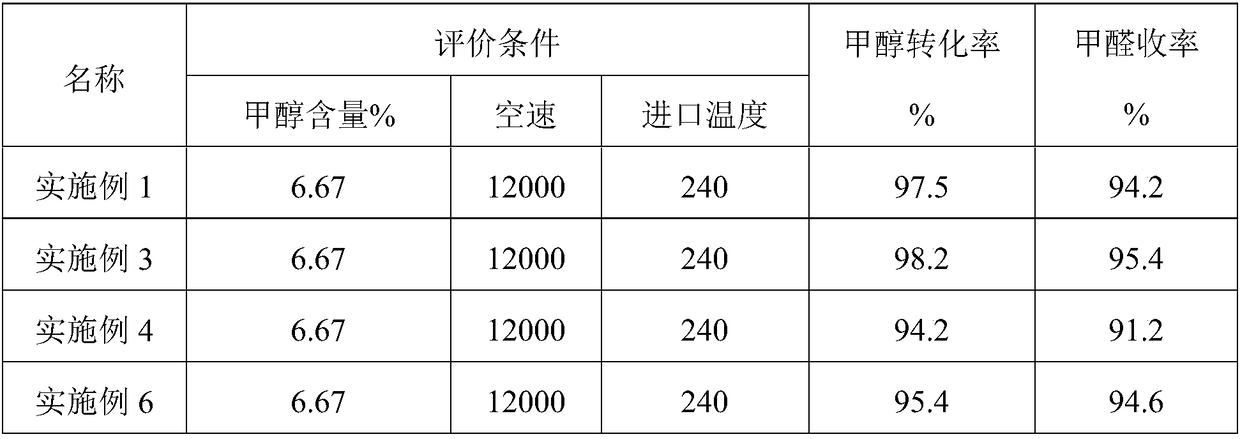

Examples

Embodiment 1

[0017] Under the condition of 30 DEG C, molybdenum porphyrin and iron porphyrin macromolecular heterocyclic compound were dissolved in chloroform in sequence, the concentration of iron porphyrin in the obtained solution was 0.1 mol / L, and the concentration of molybdenum porphyrin was 0.25 mol / L. Then add a certain amount of polyvinylpyrrolidone so that the concentration in the solution is 0.25mol / L. Subsequently, the solvent was evaporated to dryness at a temperature of 80°C and a humidity of 60%, to obtain nanostructures with specific sizes and shapes. Next, the calcination treatment was carried out at 400°C for 24 hours under the air condition to obtain the iron-molybdenum-based catalyst for the oxidation of methanol to formaldehyde (MoO 3 -Fe 2 (MoO 4 ) 3 ).

Embodiment 2

[0018] Embodiment 2: different molybdenum-iron atomic ratios (Mo / Fe=5)

[0019] Under the condition of 30 DEG C, molybdenum porphyrin and iron porphyrin macromolecular heterocyclic compound were dissolved in chloroform in sequence, the concentration of iron porphyrin in the obtained solution was 0.5 mol / L, and the concentration of molybdenum porphyrin was 2.5 mol / L. Then add a certain amount of polyvinylpyrrolidone so that the concentration in the solution is 0.25mol / L. Subsequently, the solvent was evaporated to dryness at a temperature of 80°C and a humidity of 60%, to obtain nanostructures with specific sizes and shapes. Next, the calcination treatment was carried out at 400°C for 8 hours under air conditions to obtain a series of iron-molybdenum-based catalysts for the oxidation of methanol to formaldehyde (MoO 3 -Fe 2 (MoO 4 ) 3 ).

Embodiment 3

[0020] Embodiment 3: different molybdenum-iron atomic ratios (Mo / Fe=1.5)

[0021] Under the condition of 30 DEG C, molybdenum porphyrin and iron porphyrin macromolecular heterocyclic compound were sequentially dissolved in chloroform, the concentration of iron porphyrin in the obtained solution was 1.0 mol / L, and the concentration of molybdenum porphyrin was 1.5 mol / L. Then add a certain amount of polyvinylpyrrolidone so that the concentration in the solution is 0.25mol / L. Subsequently, the solvent was evaporated to dryness at a temperature of 80°C and a humidity of 60%, to obtain nanostructures with specific sizes and shapes. Next, the calcination treatment was carried out under the air condition of 400°C for 4 hours to obtain a series of iron-molybdenum-based catalysts for the oxidation of methanol to formaldehyde (MoO 3 -Fe 2 (MoO 4 ) 3 ).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com