Magnetic adsorption units and magnetic adsorption caterpillar

A magnetic adsorption and crawler technology, applied in crawler vehicles, motor vehicles, transportation and packaging, etc., can solve the problems of poor stability, inconvenient robot movement, complex structure, etc., and achieve the effect of large load capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

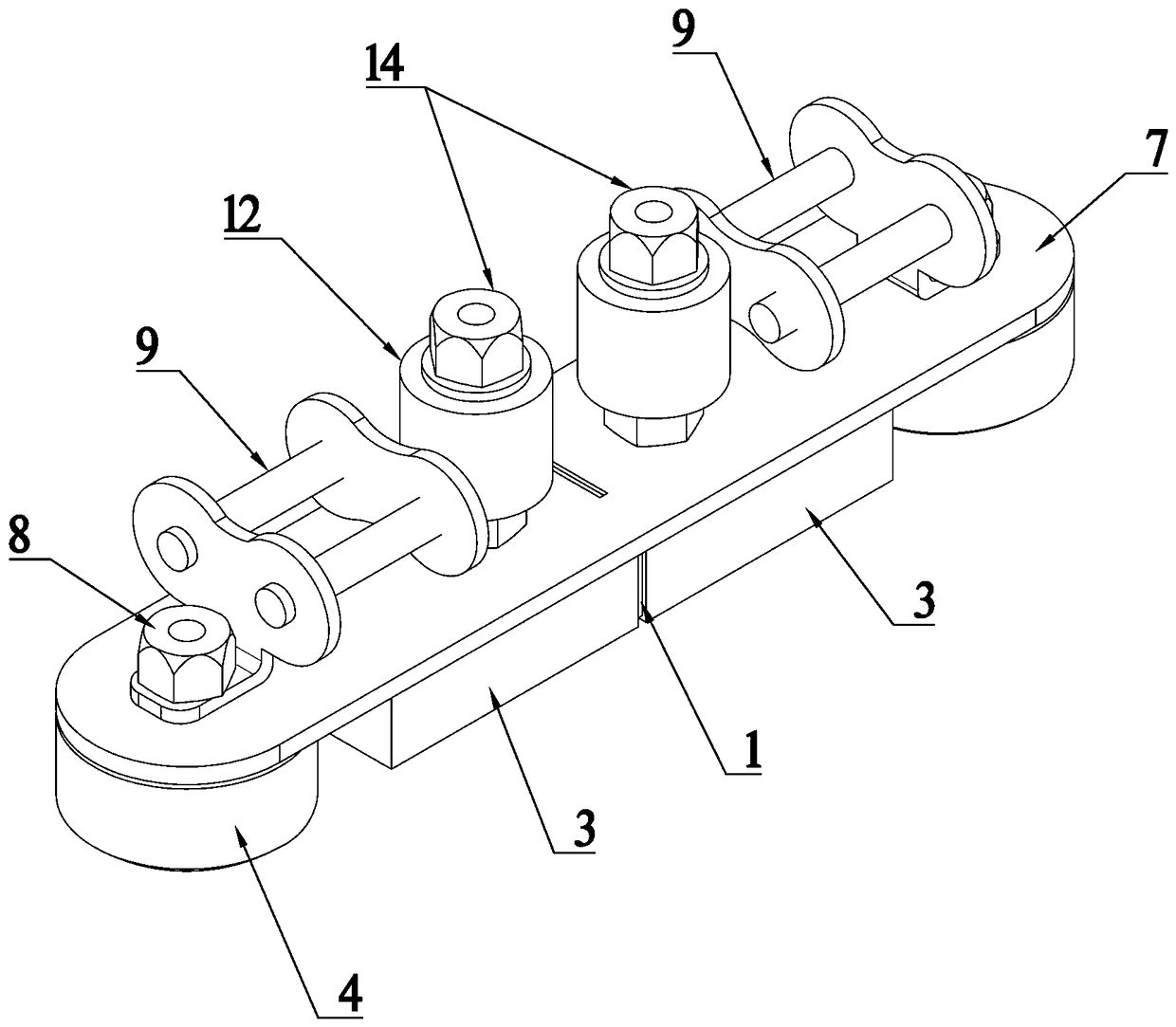

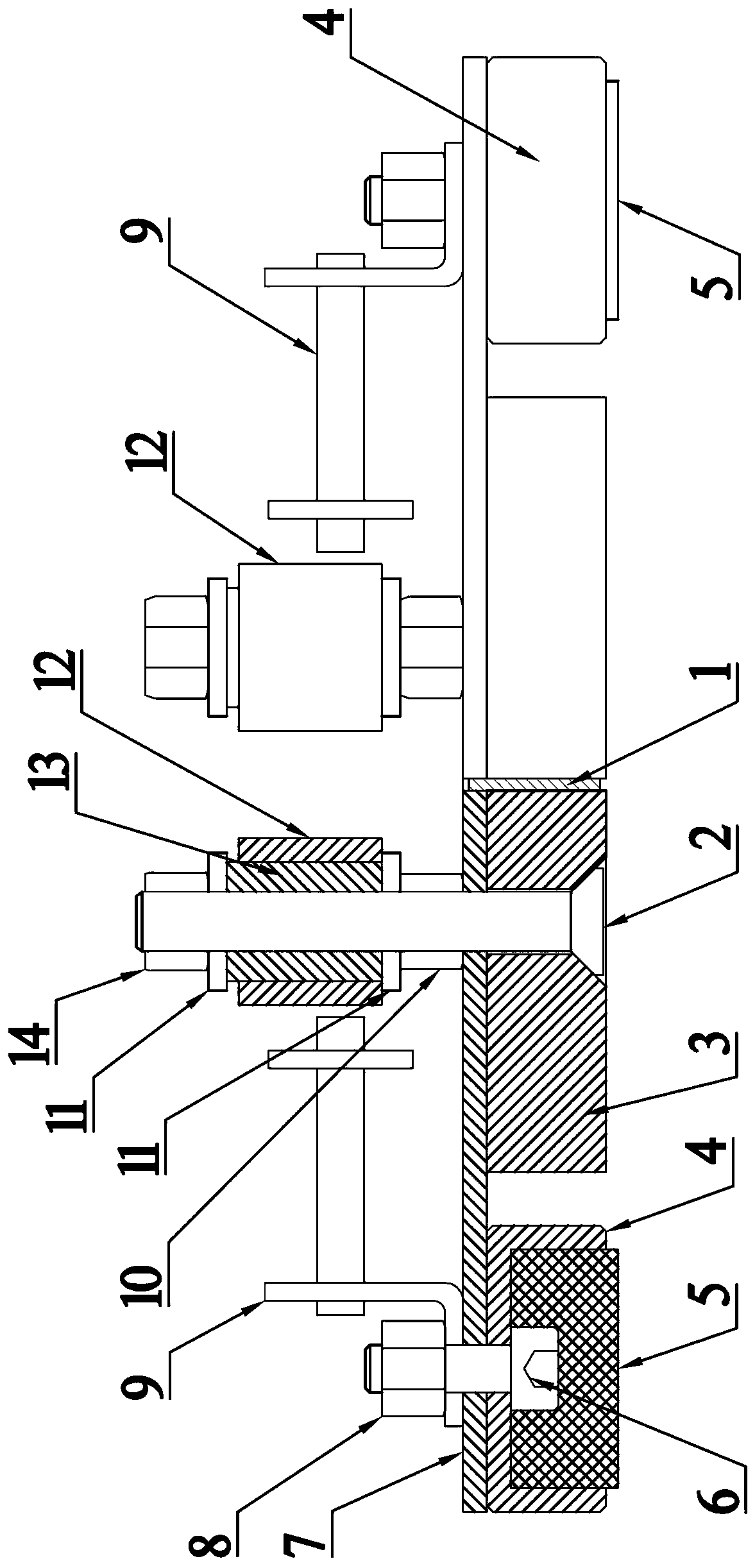

[0033] Such as Figure 1-4 The shown magnetic adsorption unit includes a base plate 7, which is in the shape of a slat, and its two ends are semicircular structures. One side of the base plate 7 is fixedly provided with a magnet 3, and the other side is provided with a guide anti-off mechanism. The guide anti-off mechanism includes two columns symmetrically arranged on the base plate 7, and a guide sleeve is arranged on the upright column. The gap between the first column and the guide sleeve is used for embedding the guide plate. Described magnet 3 adopts powerful magnet.

[0034] Two magnets 3 are arranged side by side on the said substrate 7, and a magnet spacer 1 is arranged between the two magnets 3, and the adsorption force of the two magnets 3 can be enhanced by the magnet spacer 1, and the said substrate 7 is provided with a fixing groove 15 , the magnet separator 1 is fixedly arranged in the fixing groove 15 .

[0035] The two magnets 3 are fixed on the base plate ...

Embodiment 2

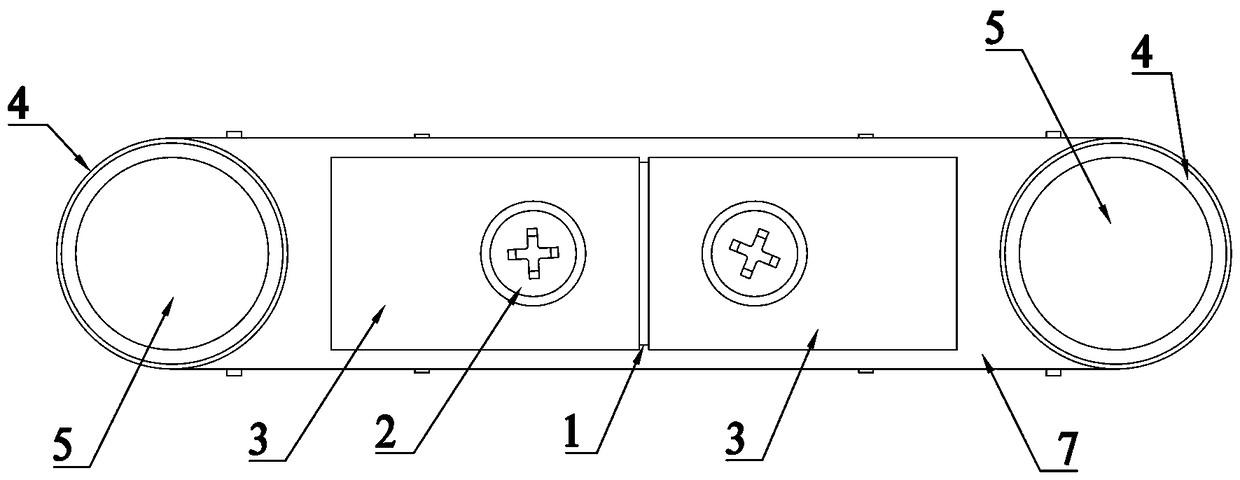

[0040] Such as Figure 5 with Image 6 A magnetic adsorption crawler is shown, which includes several magnetic adsorption units as described in Embodiment 1. Bending plate chain links 9 are respectively fixedly arranged on both sides of the guide anti-off mechanism, and between several magnetic adsorption units The magnetic adsorption track is formed by connecting the bent plate chain links 9 with each other.

[0041] In other words, the magnetic adsorption track includes two curved plate chains arranged side by side, and the curved plate chains are connected end to end to form a closed loop. The two ends of the magnetic adsorption unit described in the first embodiment are fixed on the chains of the curved plate chains. The section rotates accordingly.

[0042] The middle part of the inner side of the magnetic adsorption crawler is equipped with a continuous guide anti-off mechanism, which is used to cooperate with the anti-off guide plate of the driving mechanism of the wa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com