Green preparation method of high-quality graphene

A graphene, high-quality technology, applied in the field of graphene, can solve the problems of low quality, many redox reaction defects, etc., to achieve the effect of improving reaction efficiency, improving permeability and adsorption, and increasing fragmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of green preparation method of high-quality graphene, described preparation method comprises the steps:

[0034] Step 1, adding graphene oxide to absolute ethanol for gradient ultrasonic reaction for 3 hours, and obtaining graphene oxide alcohol solution after cooling;

[0035] Step 2, subjecting the graphene oxide alcohol solution to a sealed microwave reaction for 3 hours, and obtaining a graphene oxide dispersion after cooling;

[0036] Step 3, adding glucose to deionized water, stirring and dissolving, then slowly adding it dropwise to the graphene oxide dispersion, sealing, heating and pressurizing for 2 hours, and sealing and aerating for 3 hours, to obtain the graphene dispersion;

[0037] Step 4, ultrasonicating the graphene dispersion in a water bath for 10 hours, then filtering, washing and drying to obtain graphene.

[0038] The mass concentration of graphene oxide in the dehydrated alcohol in described step 1 is 20g / L.

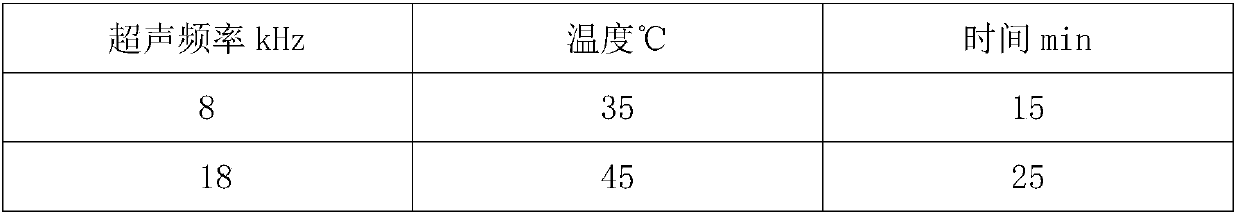

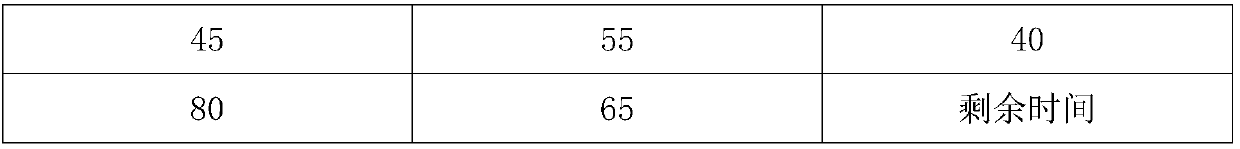

[0039] The gradient program ...

Embodiment 2

[0049] A kind of green preparation method of high-quality graphene, described preparation method comprises the steps:

[0050] Step 1, adding graphene oxide to absolute ethanol for gradient ultrasonic reaction for 5 hours, and obtaining graphene oxide alcohol solution after cooling;

[0051] Step 2, subjecting the graphene oxide alcohol solution to a sealed microwave reaction for 4 hours, and obtaining a graphene oxide dispersion after cooling;

[0052] Step 3, adding glucose to deionized water, stirring and dissolving, then slowly adding it dropwise to the graphene oxide dispersion, sealing, heating and pressurizing for 4 hours, sealing and aerating for 5 hours, to obtain the graphene dispersion;

[0053] Step 4, ultrasonicating the graphene dispersion in a water bath for 15 hours, then filtering, washing and drying to obtain graphene.

[0054] The mass concentration of graphene oxide in the dehydrated alcohol in described step 1 is 40g / L.

[0055] The gradient program of t...

Embodiment 3

[0065] A kind of green preparation method of high-quality graphene, described preparation method comprises the steps:

[0066] Step 1, adding graphene oxide to absolute ethanol for gradient ultrasonic reaction for 4 hours, and obtaining graphene oxide alcohol solution after cooling;

[0067] Step 2, subjecting the graphene oxide alcohol solution to a sealed microwave reaction for 4 hours, and obtaining a graphene oxide dispersion after cooling;

[0068] Step 3, adding glucose to deionized water, stirring and dissolving, then slowly adding it dropwise to the graphene oxide dispersion, sealing, heating and pressurizing for 3 hours, sealing and aerating for 4 hours, to obtain the graphene dispersion;

[0069] Step 4, ultrasonicating the graphene dispersion in a water bath for 12 hours, then filtering, washing and drying to obtain graphene.

[0070] The mass concentration of graphene oxide in the dehydrated alcohol in described step 1 is 30g / L.

[0071] The gradient program of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com