Hexanitrohexaazaisowurtzitane and nitroguanidine cocrystallized explosive and preparation method thereof

A technology of hexanitrohexaazane and isowurtzitane, which is applied in the field of preparation of hexanitrohexaazaisowurtzitane and nitroguanidine eutectic explosives, can solve the problem of difficulty in selecting ratios and solvents, differences in physicochemical properties, CL -20/NQ eutectic explosive has no publicity and other problems, and achieves the effect of good application prospect and high energy density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Add 40ml of methanol into the three-necked flask, accurately weigh 52mg of nitroguanidine and add it into the there-necked flask, heat up to 45°C under stirring conditions until the nitroguanidine is completely dissolved, and filter to obtain a hot saturated solution. While keeping at 45°C, add 109.5 mg of hexanitrohexaazaisowurtzitane, stir until it is completely dissolved, and continue mixing and stirring for 60 minutes. Then transfer the solution to a beaker while it is hot, stop stirring and cool down to 40°C, keep the temperature for 2 hours, follow the procedure of keeping it warm for 2 hours after each decrease of 5°C, and finally lower it to room temperature 20°C, and put it in a ventilated place for 1-2 hours. Days, solvent volatilization nuclei formed and grew up to precipitate crystals, which were filtered and dried to obtain CL-20 / NQ co-crystals.

Embodiment 2

[0019] Add 80ml of methanol into the three-necked flask, accurately weigh 104mg of nitroguanidine and add it into the there-necked flask, raise the temperature to 50°C under stirring conditions, until the nitroguanidine is completely dissolved, and filter to obtain a hot saturated solution. While keeping at 50°C, add 218 mg of hexanitrohexaazaisowurtzitane, stir until it is completely dissolved, and continue mixing and stirring for 60 minutes. Then transfer the solution to a beaker while it is hot, stop stirring and cool down to 45°C, keep the temperature for 2 hours, follow the procedure of keeping the temperature for 2 hours after each decrease of 5°C, and finally lower it to room temperature 20°C, and put it in a ventilated place for 1-2 hours. Days, solvent volatilization nuclei formed and grew up to precipitate crystals, which were filtered and dried to obtain CL-20 / NQ co-crystals.

Embodiment 3

[0021] Add 40ml of methanol into the three-necked flask, accurately weigh 120mg of nitroguanidine and add it into the there-necked flask, heat up to 55°C under stirring conditions, until the nitroguanidine is completely dissolved, and filter to obtain a hot saturated solution. While keeping at 55°C, add 251 mg of hexanitrohexaazaisowurtzitane, stir until it is completely dissolved, and continue mixing and stirring for 60 minutes. Then transfer the solution to a beaker while it is hot, stop stirring and cool down to 50°C, keep the temperature for 2 hours, follow the procedure of keeping the temperature for 2 hours after each decrease of 5°C, and finally lower it to room temperature 20°C, and put it in a ventilated place for 1-2 hours. Days, solvent volatilization nuclei formed and grew up to precipitate crystals, which were filtered and dried to obtain CL-20 / NQ co-crystals.

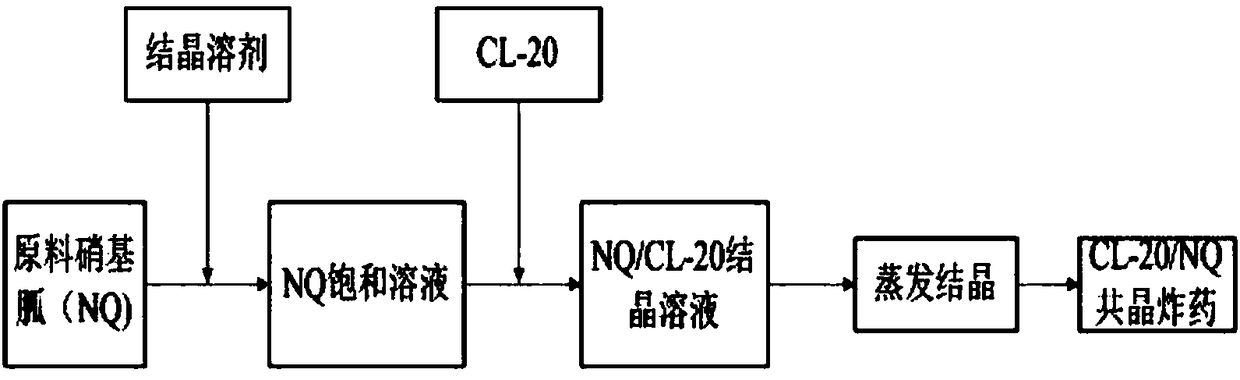

[0022] Such as figure 1 Shown is the process flow chart for the preparation of hexanitrohexaazaisowurt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com