High-strength torsion resistant steel and preparation method thereof

A high-strength, breaking steel technology, applied in the field of metal smelting, can solve the problems of twist breaking, safety and property impact, poor toughness, etc., and achieve the effect of improving toughness, improving mechanical properties, and improving plasticity and toughness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

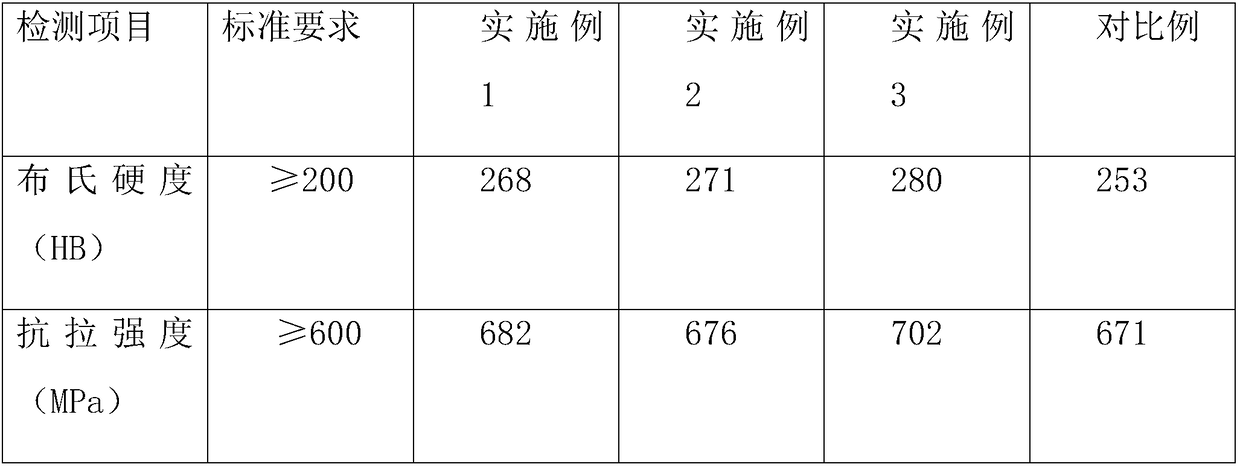

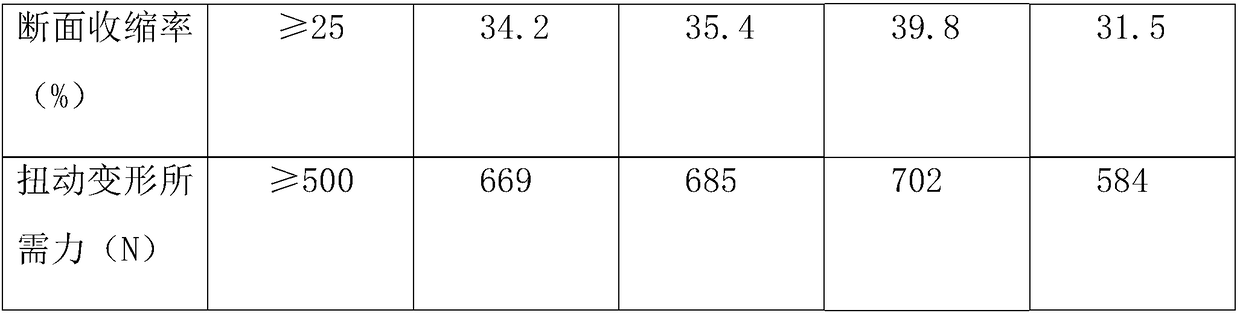

Examples

Embodiment 1

[0028] A high-strength torsion-resistant steel provided in this example has the following mass percentages of chemical components: C: 0.22%, Co: 1.25%, Ni: 0.88%, Cr: 4.57%, Mo: 0.96%, Al: 0.53 %, Ti: 0.58%, Si: 0.16%, V: 0.09%, W: 0.13%, Nb: 0.06%, Ca: 0.004%, Mn: 0.12%, styrene-butadiene-styrene block copolymer : 0.06%, rare earth element: 1.66%, the balance is Fe and unavoidable impurities.

[0029] Wherein, the rare earth elements are composed of La, Ce, Pr, Tb, and Tm in a mass ratio of 1:1:1:1:1.

[0030] A method for preparing high-strength torsion-resistant steel provided in this embodiment includes the following steps:

[0031] S1: Put the remaining raw materials except styrene-butadiene-styrene block copolymer and rare earth elements into the melting furnace according to the mass percentage, smelt the raw materials into alloy solution, then perform desulfurization and deoxidation treatment, and then add refining agent to carry out Refining and slag removal;

[003...

Embodiment 2

[0040] A high-strength torsion-resistant steel provided in this example has the following mass percentages of chemical components: C: 0.49%, Co: 1.38%, Ni: 1.34%, Cr: 5.45%, Mo: 1.35%, Al: 0.59 %, Ti: 0.78%, Si: 0.19%, V: 0.14%, W: 0.16%, Nb: 0.09%, Ca: 0.009%, Mn: 0.26%, styrene-butadiene-styrene block copolymer : 0.09%, rare earth element: 2.53%, the balance is Fe and unavoidable impurities.

[0041] Wherein, the rare earth elements are composed of La, Ce, Pr, Tb, and Tm in a mass ratio of 1:1:1:1:1.

[0042] A method for preparing high-strength torsion-resistant steel provided in this embodiment includes the following steps:

[0043] S1: Put the remaining raw materials except styrene-butadiene-styrene block copolymer and rare earth elements into the melting furnace according to the mass percentage, smelt the raw materials into alloy solution, then perform desulfurization and deoxidation treatment, and then add refining agent to carry out Refining and slag removal;

[0044]...

Embodiment 3

[0052] A high-strength torsion-resistant steel provided in this embodiment has the following mass percentages of chemical components: C: 0.22-0.49%, Co: 1.25-1.38%, Ni: 0.88-1.34%, Cr: 4.57-5.45%, Mo: 0.96-1.35%, Al: 0.53-0.59%, Ti: 0.58-0.78%, Si: 0.16-0.19%, V: 0.09-0.14%, W: 0.13-0.16%, Nb: 0.06-0.09%, Ca : 0.004-0.009%, Mn: 0.12-0.26%, styrene-butadiene-styrene block copolymer: 0.06-0.09%, rare earth elements: 1.66-2.53%, and the balance is Fe and unavoidable impurities.

[0053] Wherein, the rare earth elements are composed of La, Ce, Pr, Tb, and Tm in a mass ratio of 1:1:1:1:1.

[0054] A method for preparing high-strength torsion-resistant steel provided in this embodiment includes the following steps:

[0055] S1: Put the remaining raw materials except styrene-butadiene-styrene block copolymer and rare earth elements into the melting furnace according to the mass percentage, smelt the raw materials into alloy solution, then perform desulfurization and deoxidation trea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com