High-efficiency carbon fiber pre-carbonization process and equipment

A pre-carbonization and equipment technology, which is applied in the fields of fiber chemical characteristics, textiles and papermaking, etc., can solve the problems of shortened metal muffle furnace life, affecting the performance and quality of carbon fiber, and furnace perforation, so as to reduce investment in equipment maintenance or repair , reduce the risk of fiber quality decline, and reduce the effect of deposition hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

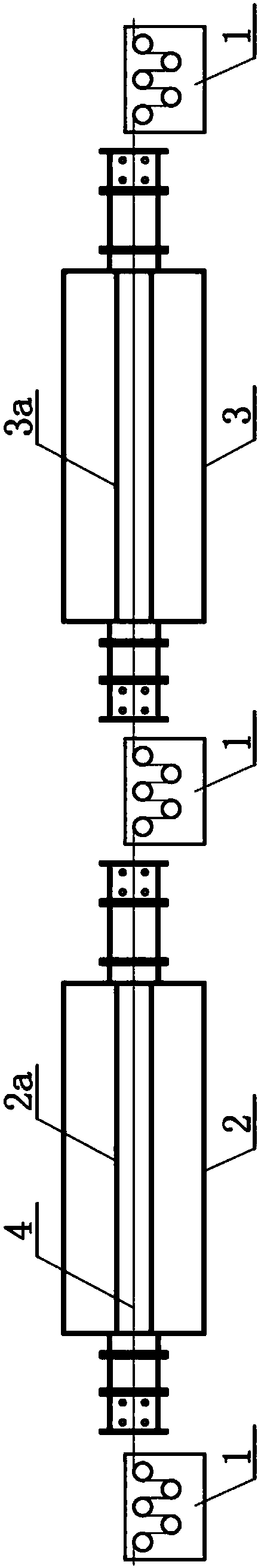

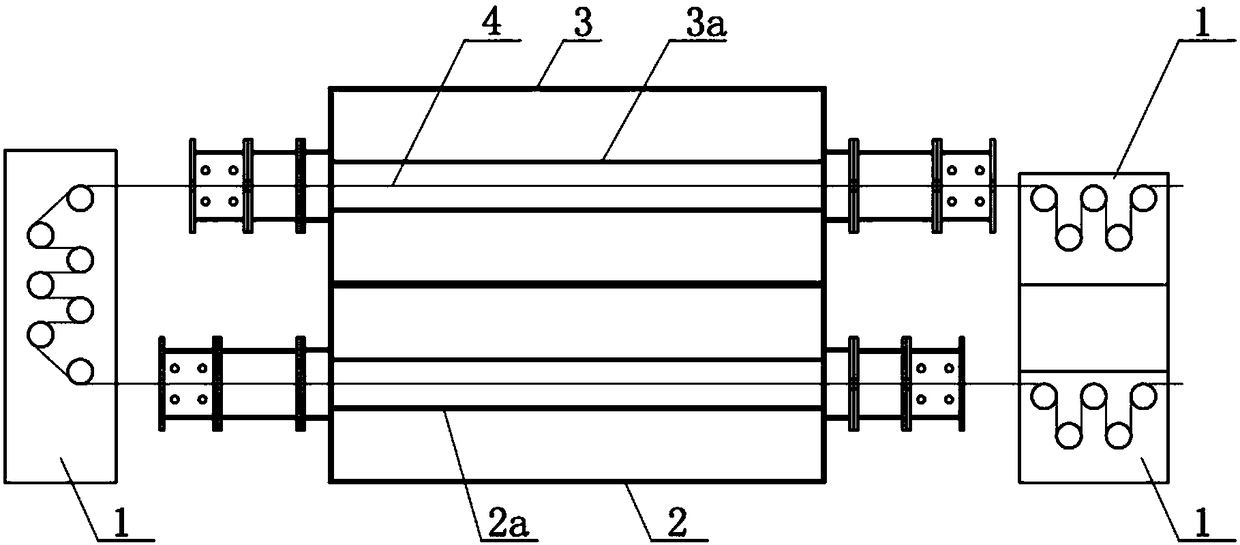

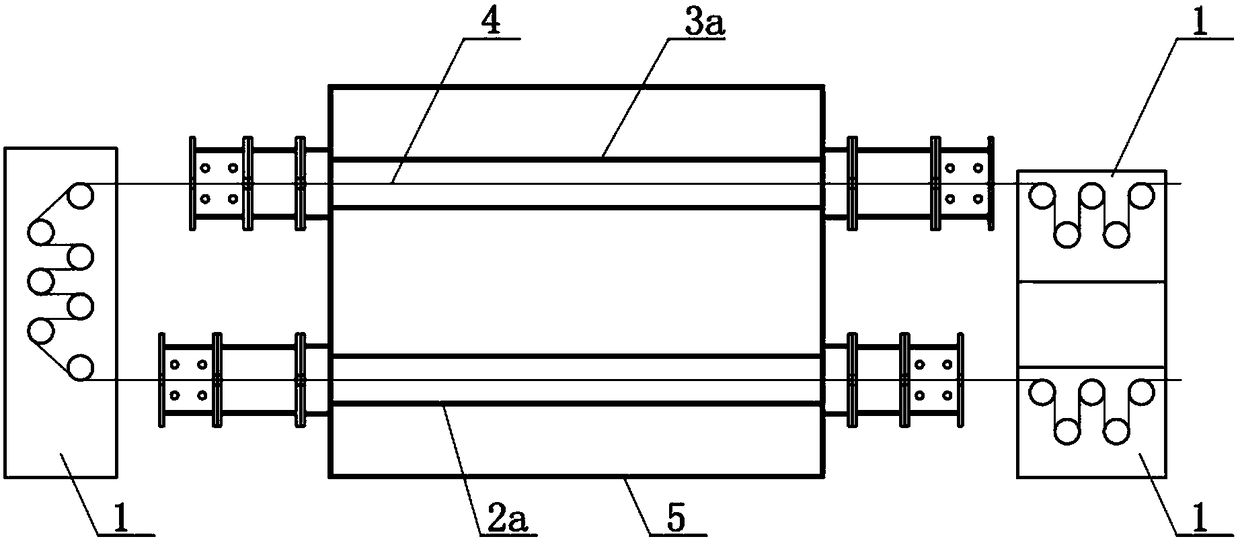

[0020] The invention relates to a high-efficiency carbon fiber pre-carbonization process and equipment. Such as figure 1 , Figure 2A and Figure 2B As shown, since the pre-carbonization thermochemical reaction is divided into two stages, the equipment order in which the fiber (4) passes through in turn is: the driving equipment (1), the muffle furnace (2a) of the first reaction stage, the driving equipment (1 ), the muffle furnace (3a) for the second reaction stage, and the drive equipment (1). The driving equipment (1) provides a tension field for the two stages of the pre-carbonization chemical reaction, the muffle furnace (2a) of the first reaction stage provides a temperature field of 300-500 degrees Celsius for the first reaction stage of the pre-carbonization, and the second The muffle furnace (3a) in the reaction stage provides a temperature field of 500-1000 degrees Celsius for the second reaction stage of pre-carbonization. High-concentration tar and waste gas ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com