Ground source well backfilling system and ground source well backfilling method

A ground-source well and ground-source technology, applied in excavation, construction, infrastructure engineering, etc., can solve problems such as poor backfill effect, easy blockage of returned materials, and unclean air discharge, so as to achieve easy blockage, good heat exchange effect, The effect of high backfill density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

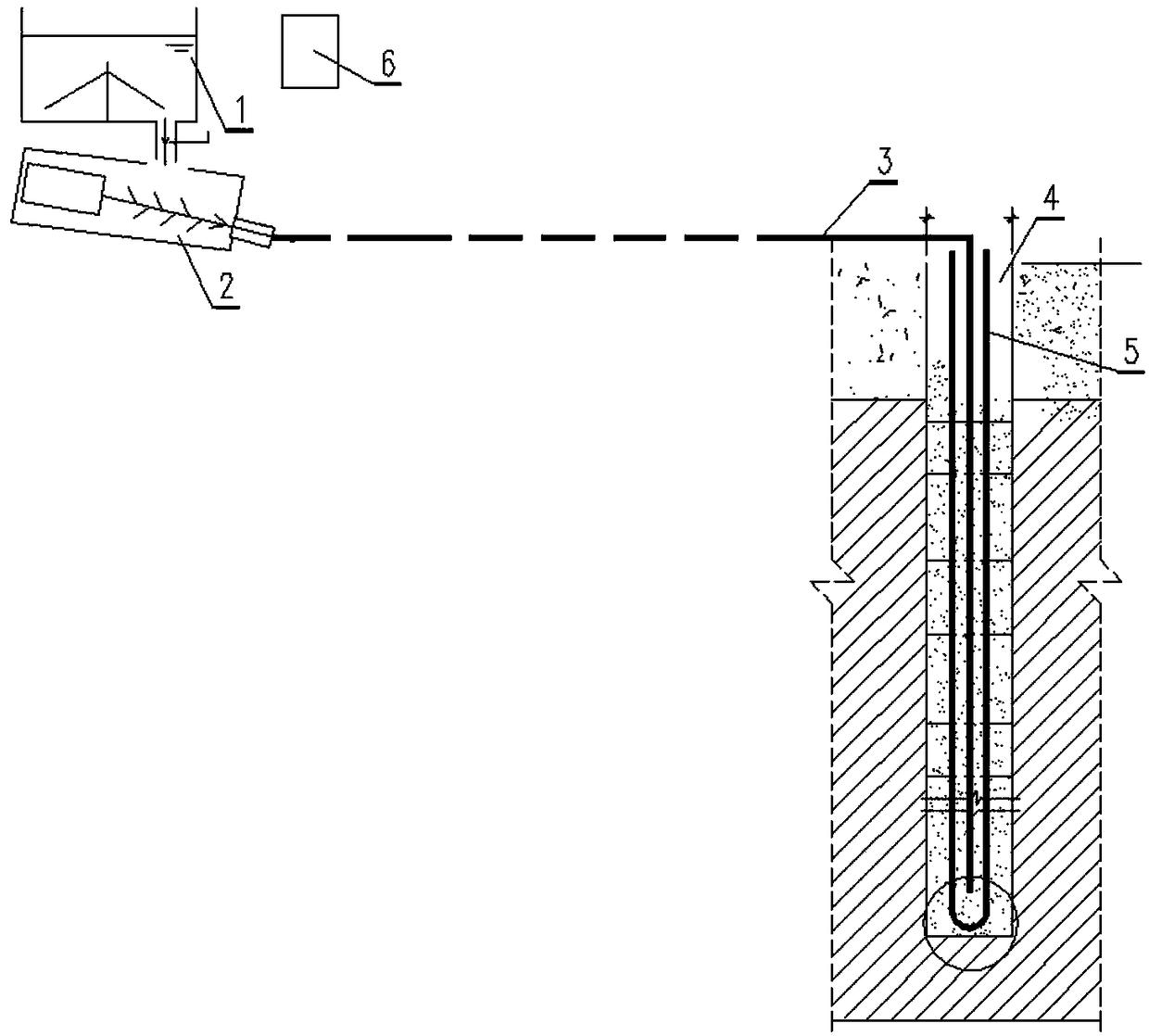

[0043] A ground source well backfilling system, comprising: a mixer 1, a grouting pump 2, a grouting pipe 3, a double U heat exchanger 5 and a pipe lifter, the mixer 1 is connected to the grouting pump 2, and the injection The grout pump 2 is connected to one end of the grouting pipe 3, the other end of the grouting pipe 3 is connected to the double U heat exchanger 5, and the pipe lifter is connected to the grouting pipe 3 for lifting the Describe the grouting pipe 3.

[0044] Further, it also includes a filler metering bucket 6 for metering the backfill material put into the mixer 1 .

[0045] Further, a controller is also included, the controller is connected with the grouting pump 2 and the pipe lifter, and is used for controlling the grouting pump 2 and the pipe lifter.

[0046] Further, the controller is a PLC control system.

[0047] Further, the grouting pump 2 is a screw type grouting pump.

[0048] The present invention also includes a ground source well backfilli...

Embodiment 2

[0076] A ground source well backfilling method, which adopts the bottom grouting backfilling construction method. The grouting pipe 3 is inserted into the bottom of the deep well together with the double U heat exchanger 5. Slurry, gradually discharge the original air and water in the well upwards; lift the pipe while grouting, until the grouting material flows out from the wellhead of the ground source, which proves that the backfill of the entire deep well has been completed and the backfill has been compacted.

[0077] The speed of lifting the grouting pipe is determined according to the volume of the backfill. The volume of the backfill is calculated from the volume of the deep well and the volume occupied by the heat exchanger, and then the backfill is calculated according to the volume of backfill into the well during the grouting process. The height of the grouting pipe can be determined according to the height of the backfill.

Embodiment 3

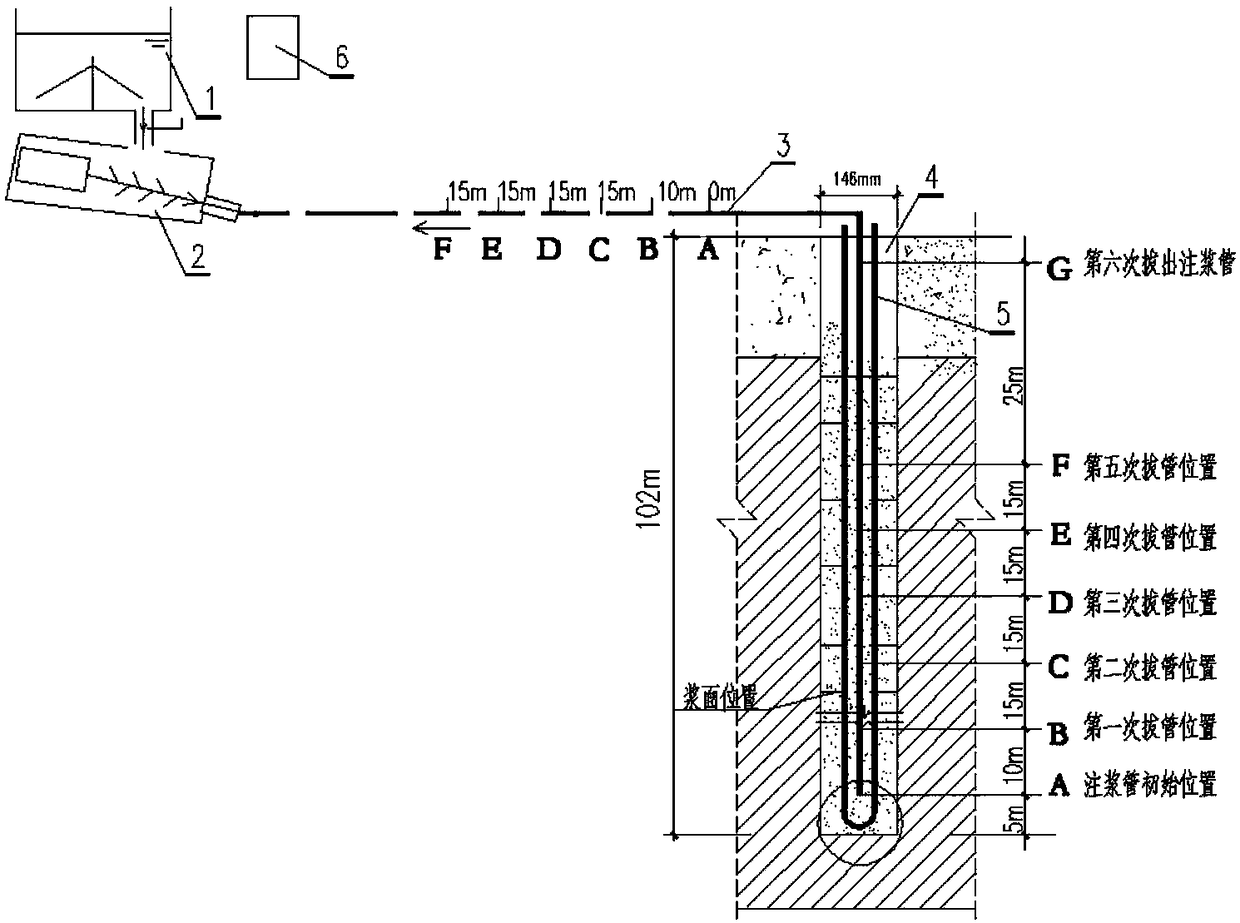

[0079] as attached figure 2 As shown, the grouting pipe 3 is inserted into the bottom of the ground source well 4 together with the double U heat exchanger 5, and the mouth of the grouting pipe is 5 meters away from the bottom of the well.

[0080] According to the volume of the deep well and the volume occupied by the heat exchanger, the volume of the backfill is calculated, and the backfill is measured by the filler metering barrel 6 and put into the mixer 1 in six times. After the grouting pump 2 is pumped into the ground source well 4, backfill is added to the mixer 1 from the filler metering barrel 6 again.

[0081] Strictly control the pulling speed of the grouting pipe during the grouting process. If it is too fast, the air in the well will not be exhausted. If it is too slow, the filler will easily squeeze the buried pipe. Do not pull the pipe until a complete tank of dry material is grouted to ensure that the grouting pipe is buried below the grout surface.

[0082...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com