Laying tool for seepage-proof coil of groove corner part

A corner and position technology is applied in the field of anti-seepage coil laying tools at the corner of grooves, and can solve the problems of difficulty in ensuring good laying quality of anti-seepage coils at corners, inability to meet environmental protection and anti-seepage requirements, and reducing construction efficiency. Achieve good laying quality and construction efficiency, low cost, and improve locking reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

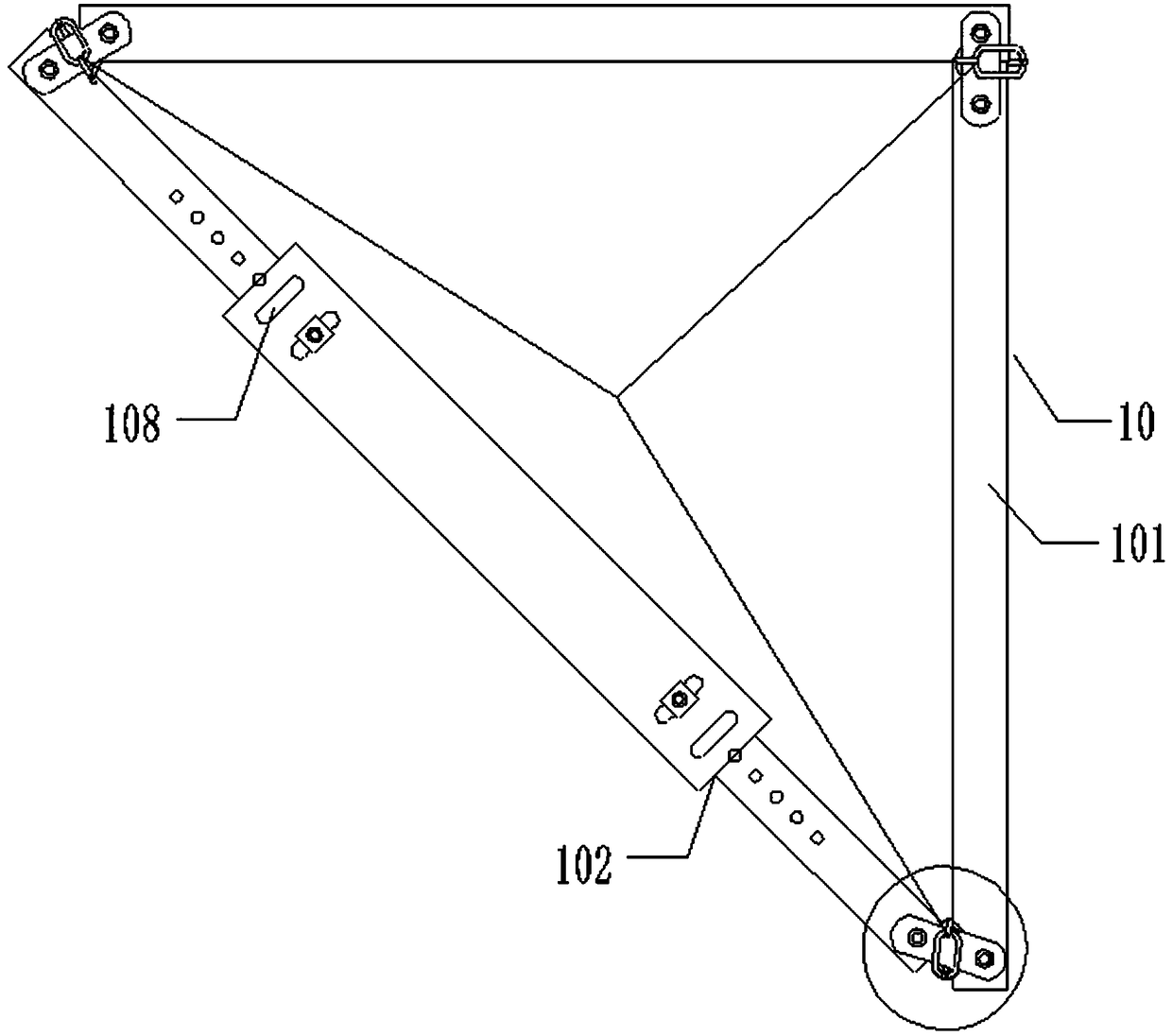

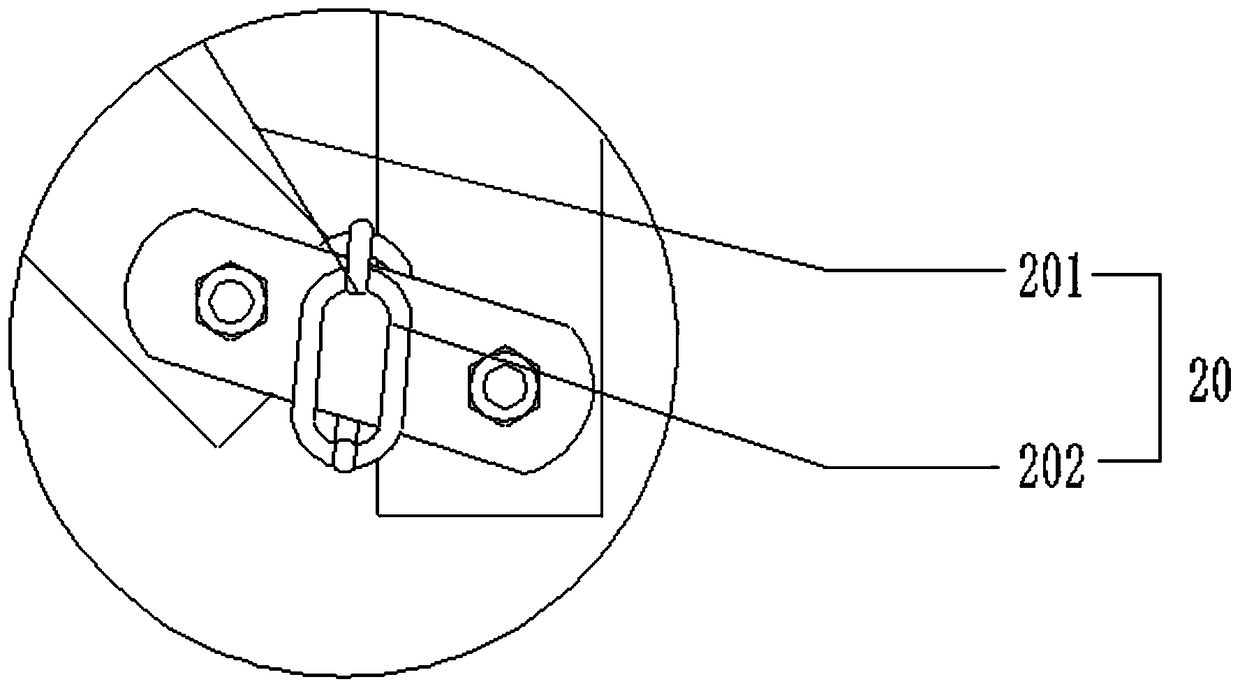

[0031] Embodiment one: if figure 1 As shown, a tool for laying anti-seepage coils at the corners of the trench, including a triangular hanger 10 and an auxiliary hoisting structure 20, the triangular hanger 10 is fixed with the auxiliary hoisting structure 20, and the triangular hanger 10 is set to be an isosceles triangle structure, the triangular hanger 10 is set to include two groups of steel waist pipes 101, steel bottom pipes 102 and connecting structures, between the beginning ends of the two groups of steel waist pipes 101, between the ends of the steel waist pipes 101 and the beginning ends of the steel bottom pipes 102 1. A connecting portion is formed between the end of the steel waist pipe 101 and the end of the steel bottom pipe 102, and the angle range between the steel waist pipe 101 and the steel bottom pipe 102 is 60°-170°, the length of the steel waist pipe 101 3.5-4.5m, through the cooperation of the isosceles triangle hanger 10 structure and the auxiliary ho...

Embodiment 2

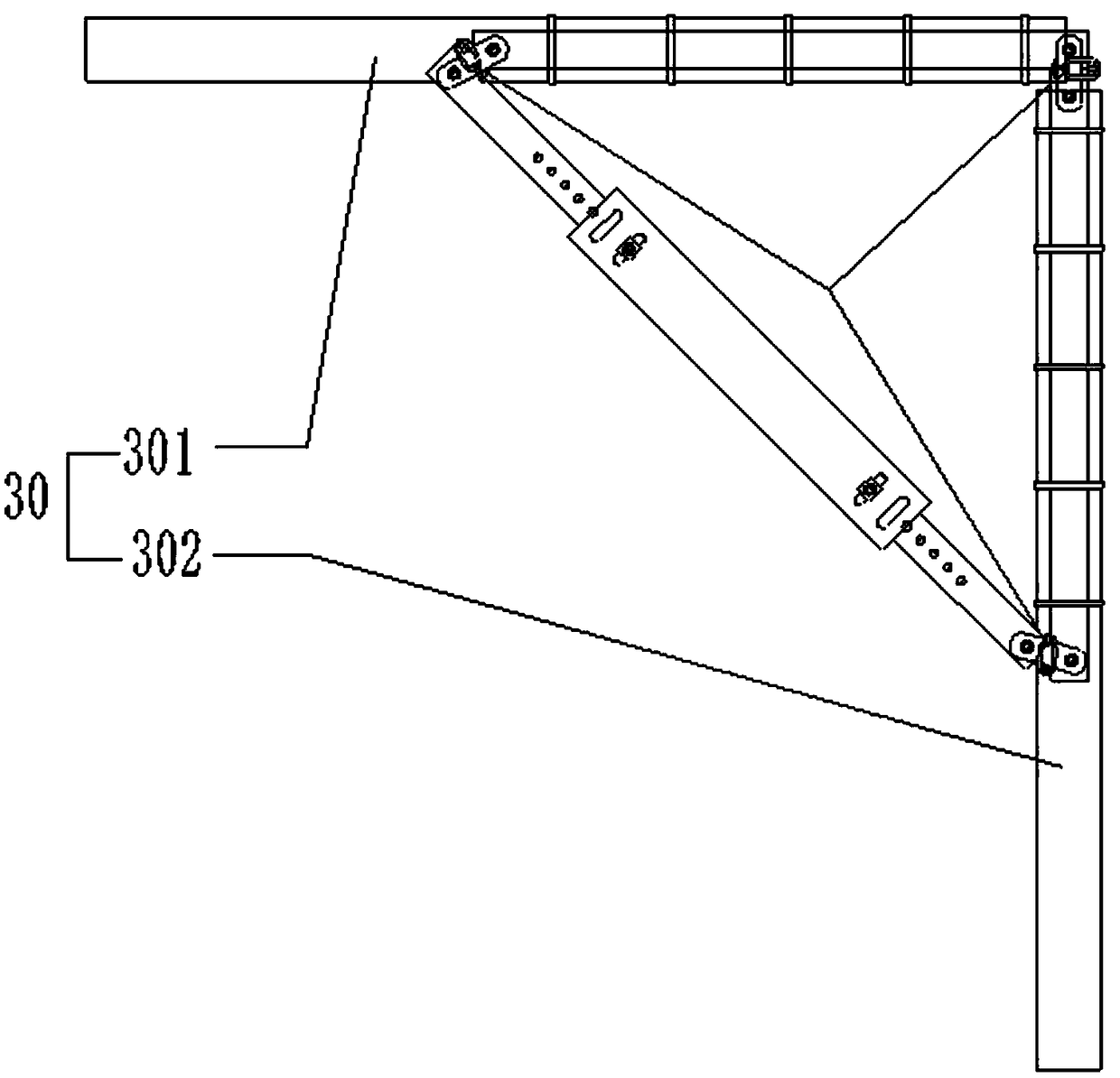

[0036] Embodiment two: if figure 2 As shown, a tool for laying anti-seepage coils at the corners of the trench, including a triangular hanger 10 and an auxiliary hoisting structure 20, the triangular hanger 10 is fixed with the auxiliary hoisting structure 20, and the triangular hanger 10 is set to be an isosceles triangle structure, the triangular hanger 10 is set to include two groups of steel waist pipes 101, steel bottom pipes 102 and connecting structures, between the beginning ends of the two groups of steel waist pipes 101, between the ends of the steel waist pipes 101 and the beginning ends of the steel bottom pipes 102 1. A connecting portion is formed between the end of the steel waist pipe 101 and the end of the steel bottom pipe 102, and the angle range between the steel waist pipe 101 and the steel bottom pipe 102 is 60°-170°, the length of the steel waist pipe 101 3.5-4.5m, through the cooperation of the isosceles triangle hanger 10 structure and the auxiliary h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com