A h-shaped shallow cavity dynamic and static pressure mixed water lubricated radial bearing with circumferential communication groove

A radial bearing, dynamic and static pressure technology, applied in the direction of bearings, shafts and bearings, bearing cooling, etc., can solve the problems of increased cost, longer production cycle, difficult accurate positioning, etc., to reduce difficulty and cost, improve control accuracy, The effect of increasing water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

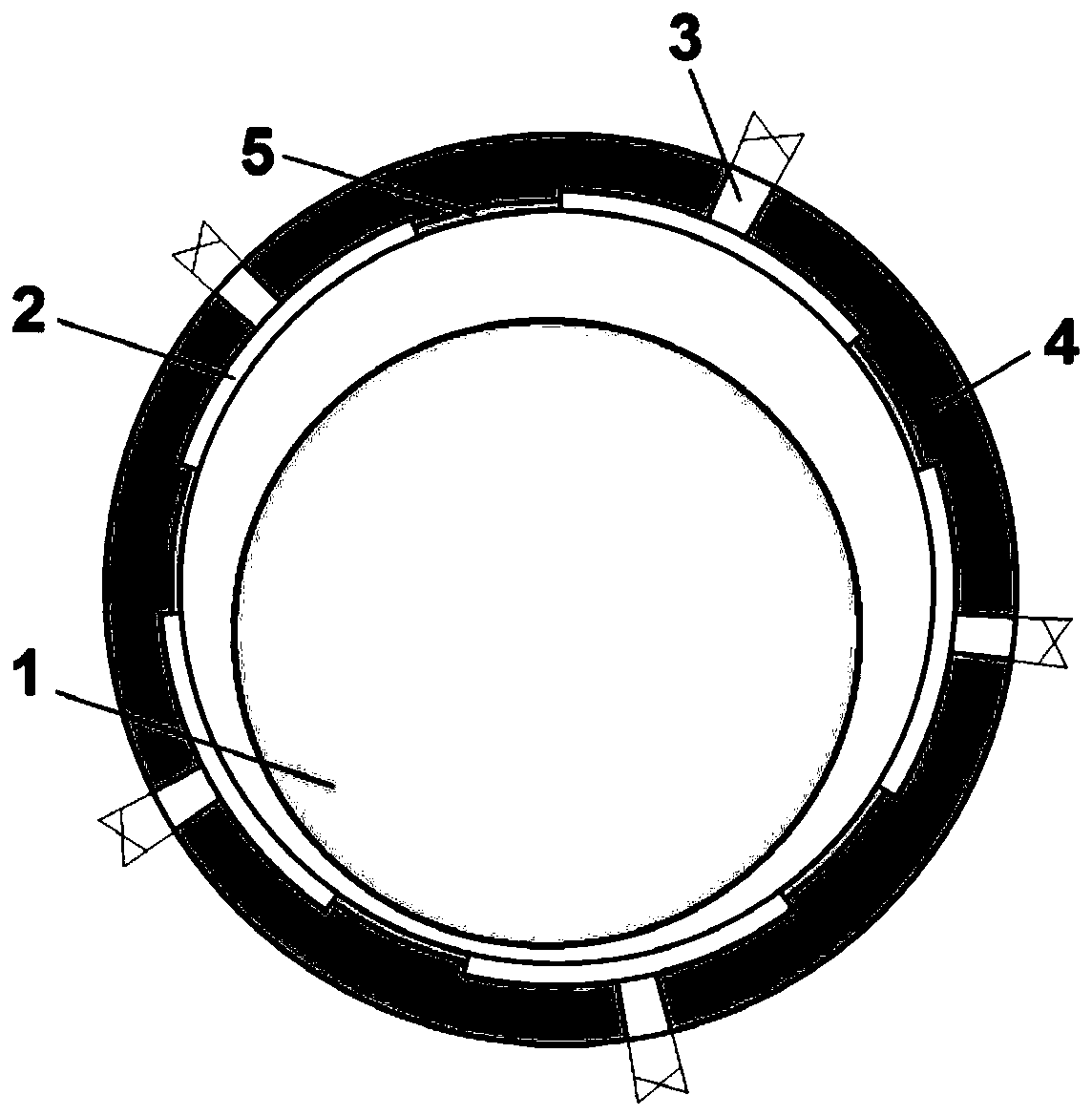

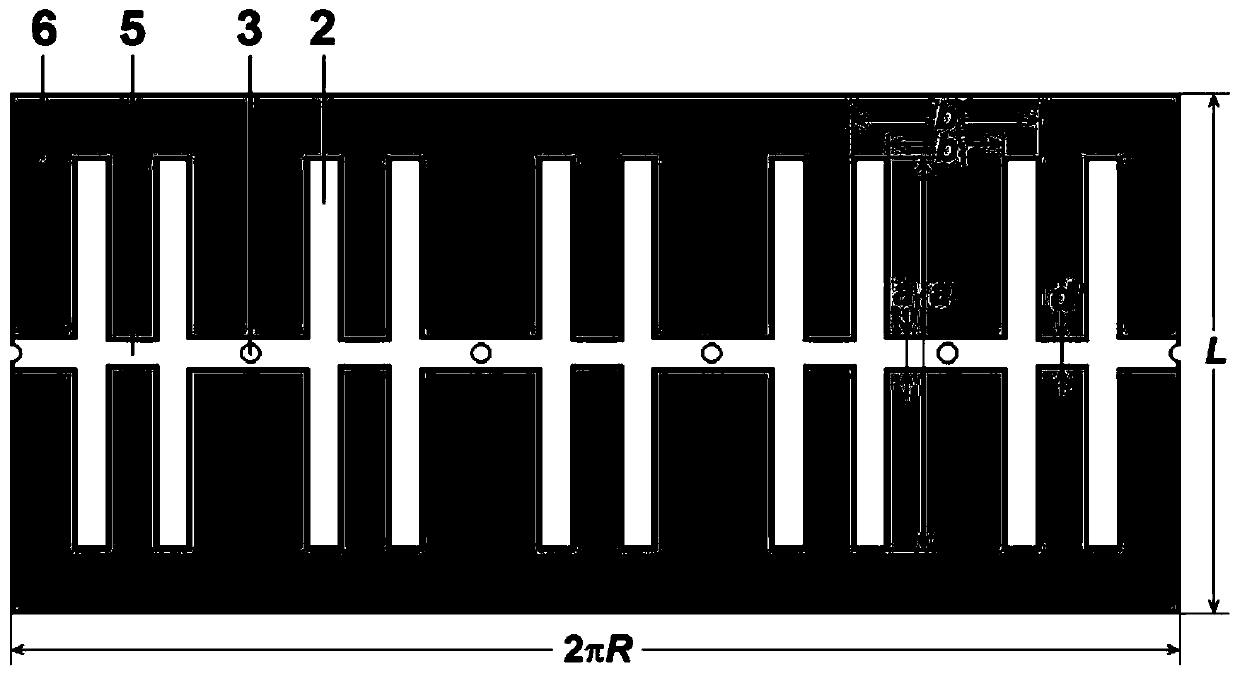

[0025] An H-shaped shallow chamber dynamic and static pressure mixed water lubricated radial bearing provided with a circumferential communication groove, including a shaft diameter 1, an H-shaped static pressure chamber 2, a throttle hole 3 of a throttle, a shaft sleeve 4, and a circumferential communication Slot 5. Five H-shaped static pressure chambers 2 are evenly arranged on the inner surface 6 of the sleeve along the circumferential direction; two adjacent H-shaped static pressure chambers 2 are communicated with each other through the annular groove communication 5 . The shaft diameter 1 is sleeved in the shaft sleeve 4 . The orifice 3 of the restrictor is arranged at the center of the transverse partition of the H-shaped static pressure chamber 2 .

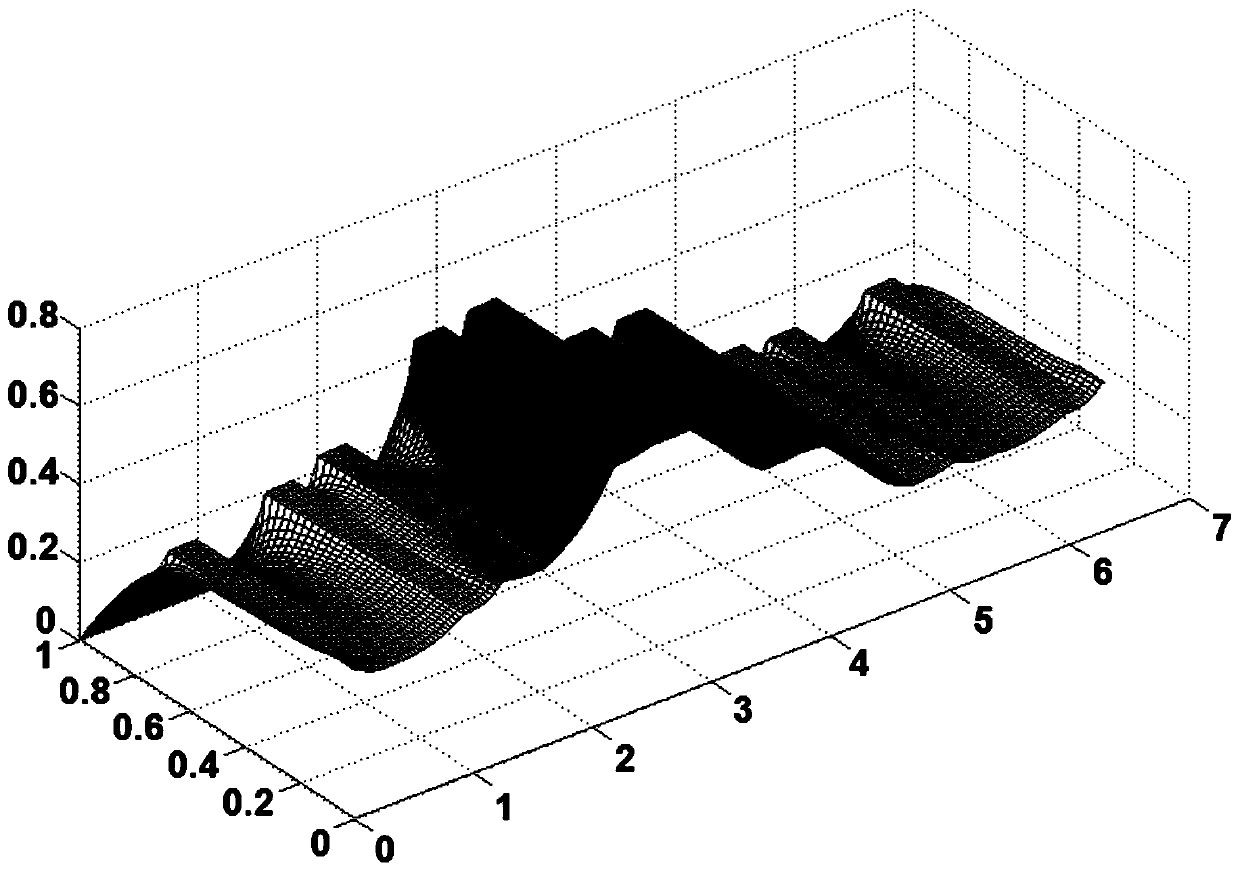

[0026] Compare image 3 , Figure 5 with Figure 7 It is possible to compare the diffe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com