Real-time monitoring gas supply device for GIS equipment storage and gas supply method

A real-time monitoring and equipment technology, applied in the direction of container discharge method, measuring device, container structure installation device, etc., can solve the problems of not installing pressure gauges and inability to ensure, so as to prevent internal corrosion, prolong life, and reduce production The effect of maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

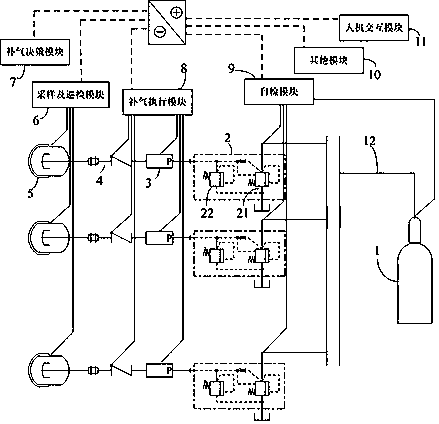

[0033] figure 1 It is the first embodiment of a real-time monitoring gas replenishing device for GIS equipment storage in the present invention, including several groups of decompression devices 2, precision pressure gauges 3, check valves 4 and air barriers connected in sequence through air guide tubes 12. Device 5, decompression device 2 is also connected with common nitrogen device 1;

[0034] It also includes a self-inspection module 9, an air supply execution module 8, a sampling and inspection module 6, and an air supply decision-making module 7. The self-inspection module 9 is connected to the nitrogen device 1 and the decompression device 2, and the air supply execution The module 8 is connected with the check valve 4 and the precision pressure gauge 3, the sampling and inspection module 6 is connected with the air separation device 5, the sampling and inspection module 6 is connected with the gas replenishment decision module 7, and the gas replenishment decision modu...

Embodiment 2

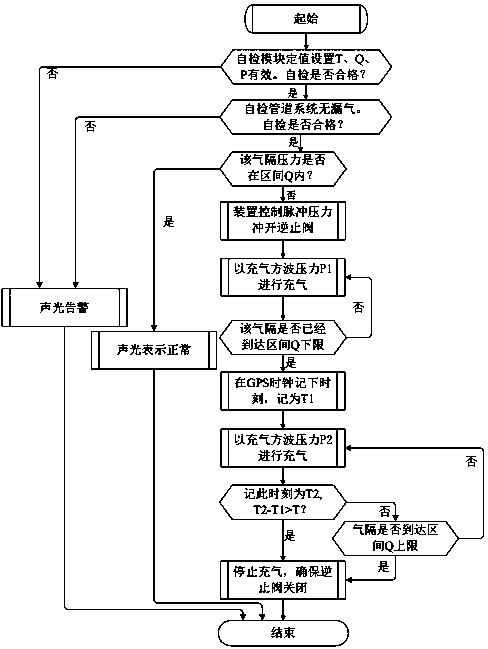

[0043] figure 2Embodiment 2 of a real-time monitoring gas supply method for GIS equipment storage of the present invention comprises the following steps:

[0044] S1: T, Q, and P are valid for the self-test module setting. Whether the self-inspection is qualified; if the self-inspection is not qualified, the sound and light alarm will directly enter the end process; if the self-inspection is qualified, perform the next step S2;

[0045] S2: After step S1, self-check whether there is air leakage in the pipeline system; if the self-inspection detects air leakage in the pipeline, an audible and visual alarm will be issued, and the end process will be directly entered; if there is no air leakage in the pipeline during the self-inspection, go to the next step S3;

[0046] S3: After step S2, judge whether the air separation pressure is in the interval Q; if the air separation pressure is in the interval Q, the sound and light indicate normal, and directly enter the end process; if...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com