Negative pressure protective fermentation tank

A protective, fermenter technology, applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc., can solve problems such as pressure drop, equipment damage, etc., to reduce the possibility, The effect of reducing losses and preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

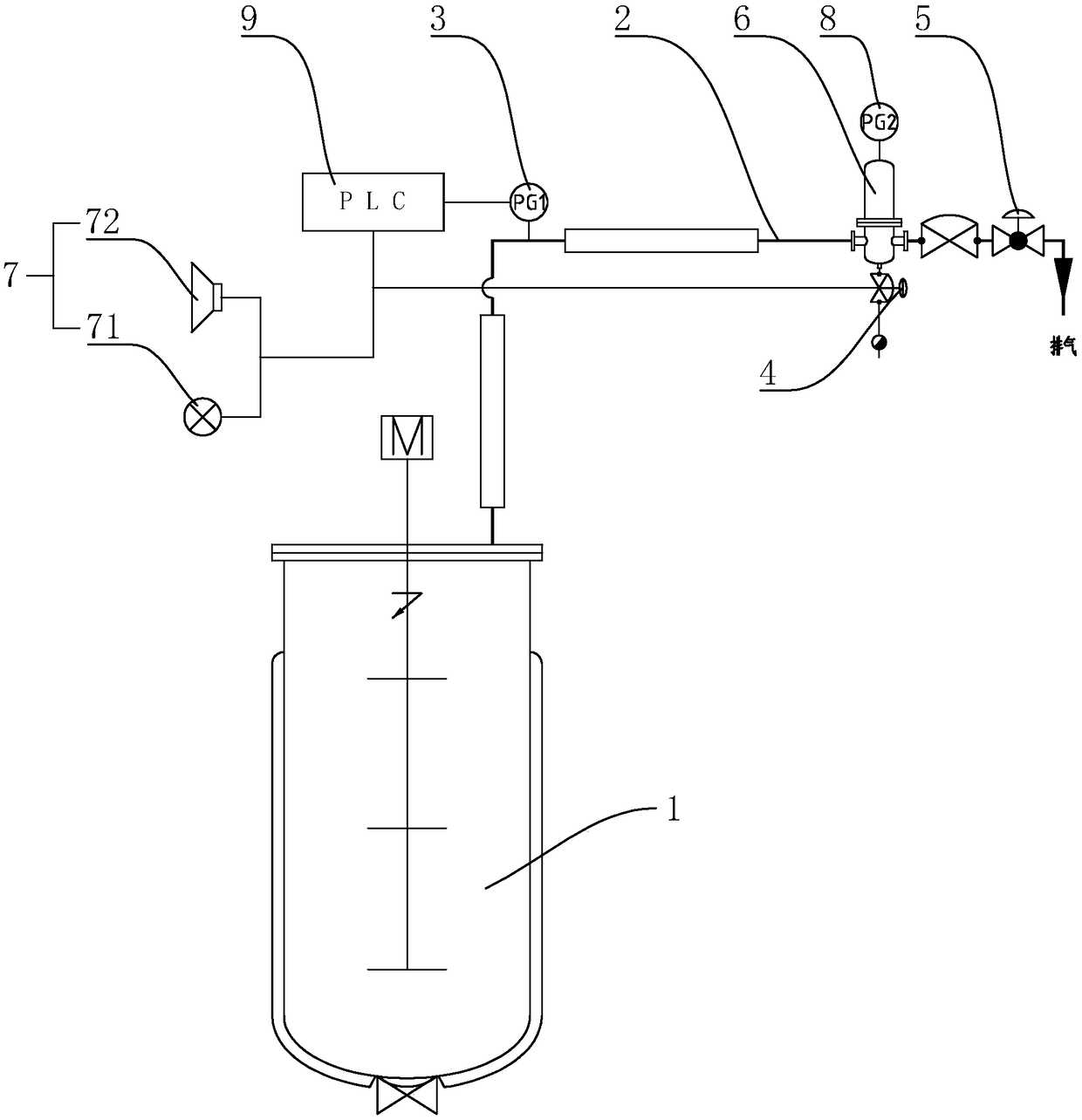

[0020] A negative pressure protection fermenter provided in this embodiment has a structure such as figure 1 As shown, it includes a tank body 1 and an exhaust pipeline 2 connected thereto. The exhaust pipeline 2 is respectively provided with a pressure transmitter 3, an exhaust valve 4 and a pressure regulating valve 5, and the pressure transmitter 3, exhaust The air valve 4 and the pressure regulating valve 5 are respectively arranged on the exhaust pipe 2 along the exhaust direction of the tank body 1 from the inside to the outside, wherein the exhaust valve 4 and the pressure regulating valve 5 are respectively made of stainless acid-resistant steel. A gas filter 6 is arranged between the exhaust valve 4 and the exhaust pipe 2 , and a pressure gauge 8 is also arranged on the gas filter 6 .

[0021] The pressure transmitter 3 is electrically connected to the control device 9, and the pressure transmitter 3 is connected to the input end of the control device 9, the control d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com