Solid material thermal physical property test system and method based on mirror image heat source principle

A technology of solid material and thermal physical property parameters, applied in the direction of thermal conductivity of materials, thermal development of materials, etc., can solve the problems of limited application scope, unfavorable experimental operation, etc., and achieve the effect of eliminating heat accumulation effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

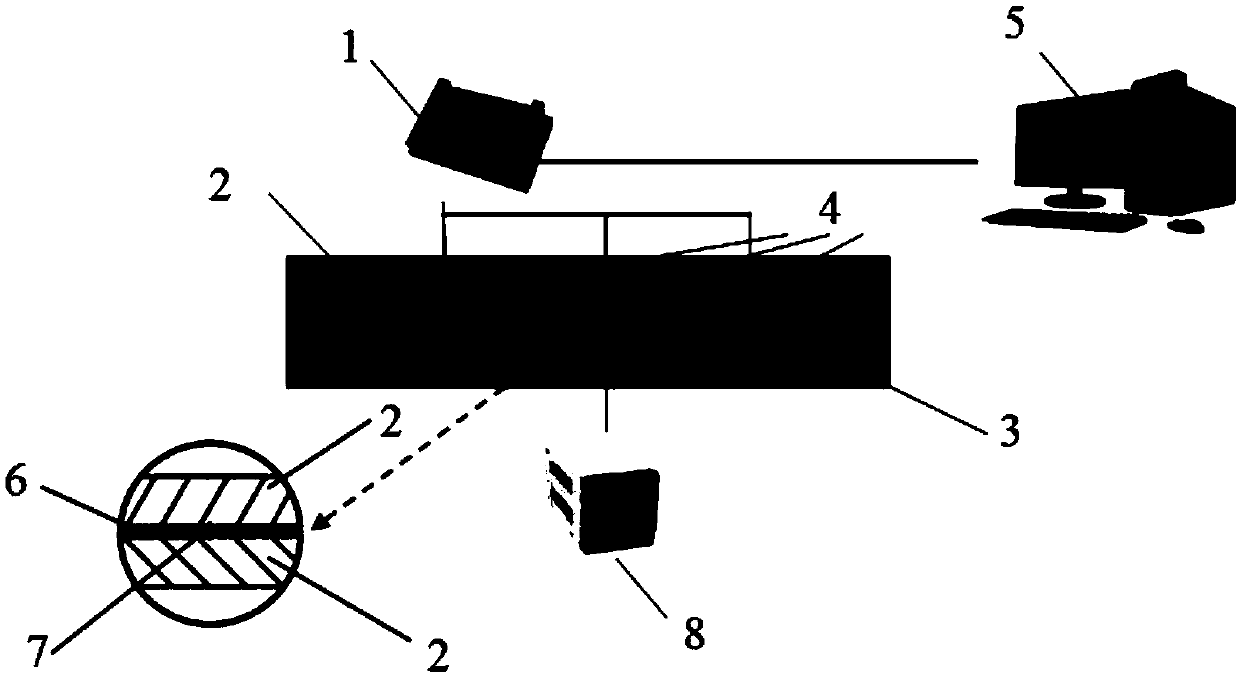

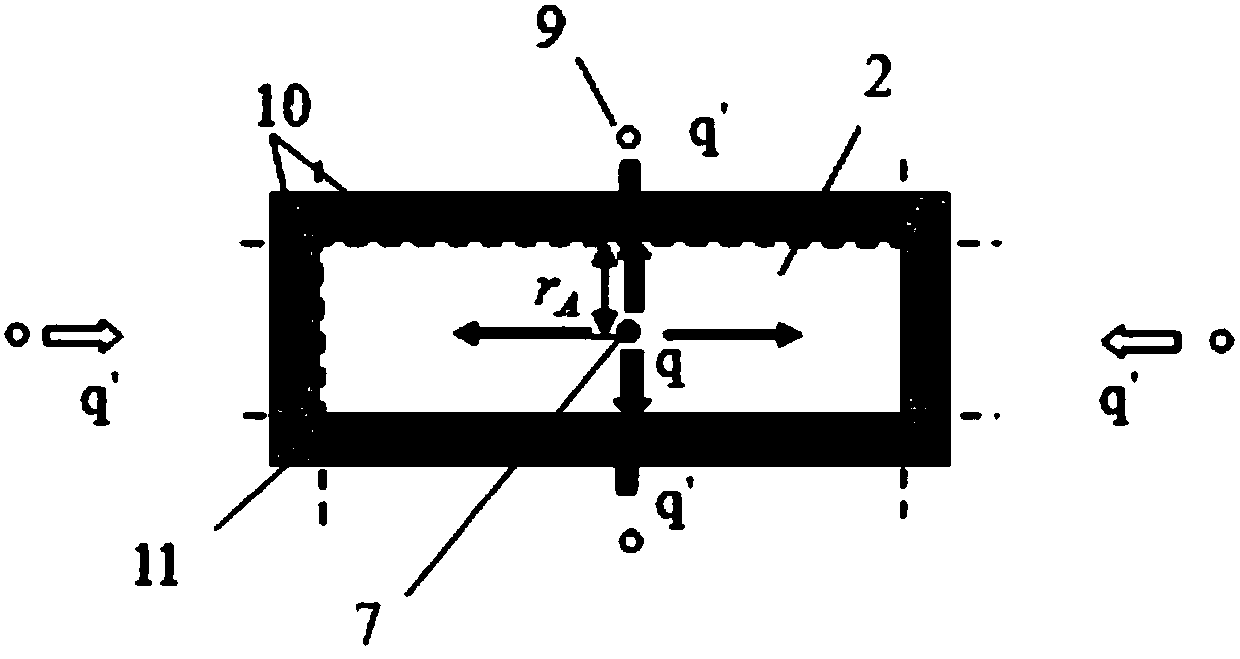

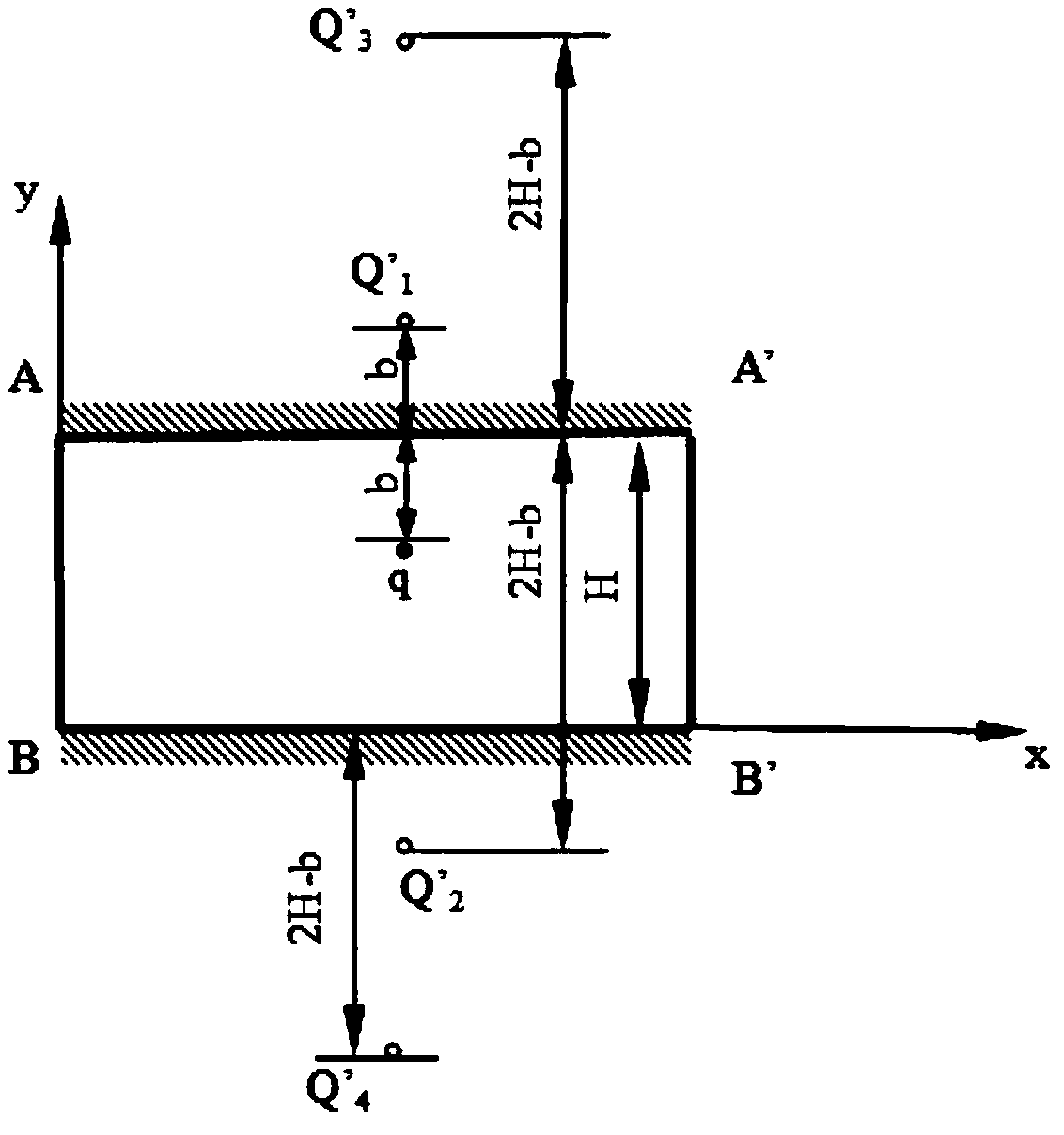

[0038] A system for measuring thermophysical parameters of solid materials based on the principle of mirror heat source, including sample 2, experimental box 3, data acquisition module and heating device. The experimental box 3 is a closed structure and its upper surface is movable with an end cover;

[0039] The data acquisition module includes a temperature measuring thermocouple 4, an AD converter 1 and a computer 5, the temperature measuring thermocouple 4 is electrically connected to the AD converter 1, and the AD converter 1 is electrically connected to the computer 5;

[0040] The heating device includes a heat source 7 and a regulated power supply 8, the heat source 7 is a heating wire, and the heating wire is electrically connected to the regulated power supply 8 and has a constant power q;

[0041] The heating wire is made of nickel-chromium resistance wire, the cross-sectional diameter of the resistance wire is 0.1 mm, the end cover is hinged on the upper surface of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com