Ring main unit with heat sink

A technology of heat dissipation device and ring network cabinet, applied in the field of ring network cabinet, can solve the problems of not really achieving high heat dissipation, single structure of heat dissipation device, burning of internal circuits, etc., so as to improve work efficiency and service life, reduce temperature, and improve use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

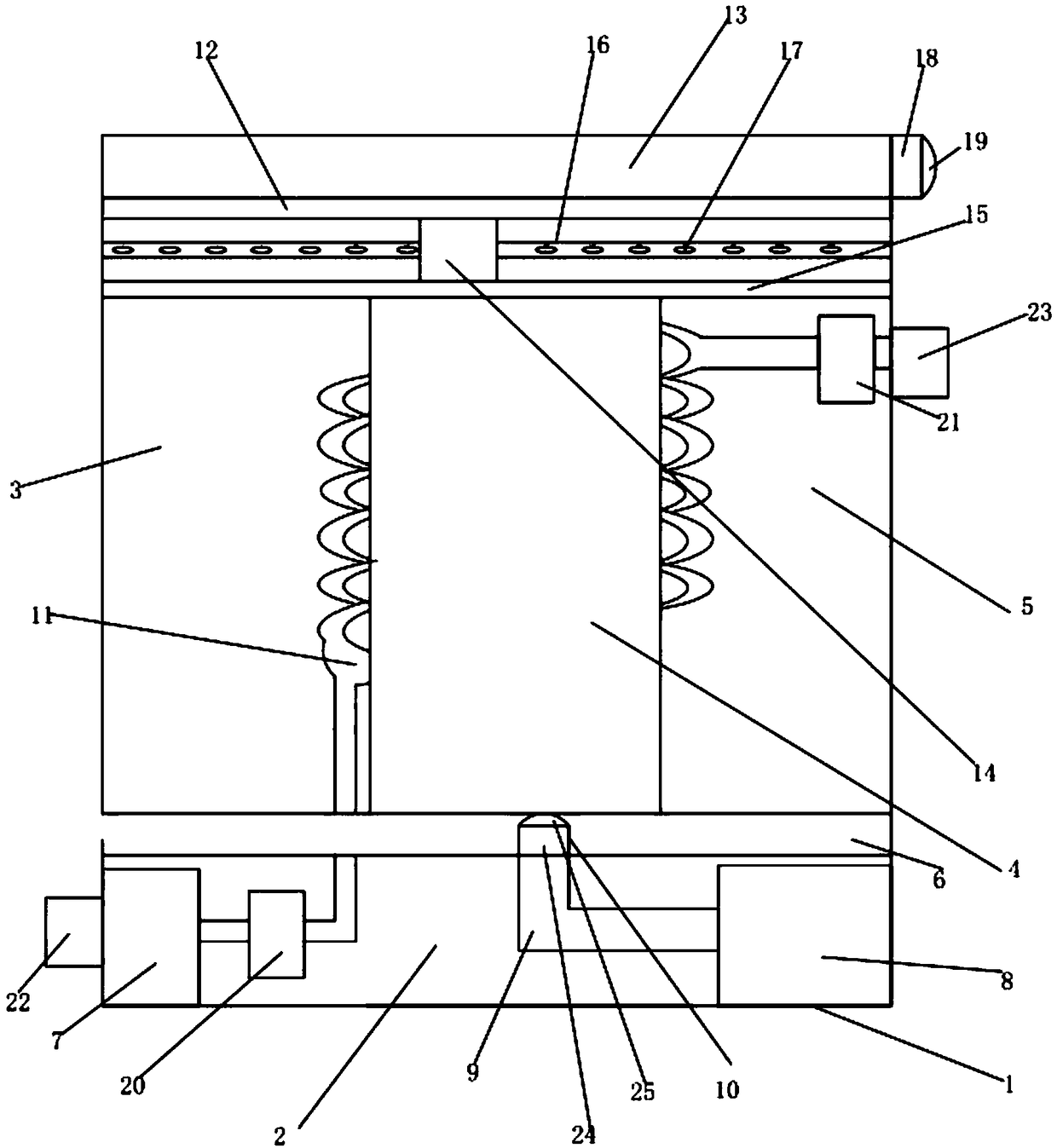

[0021] Refer to as figure 1As shown, a ring main unit with a cooling device includes a body 1 and a cooling device 2, the cooling device 2 is installed in the body 1, and a high-voltage component box 3 and a cable box 4 are also arranged in the body 1 And the operating mechanism box 5, the cable box 4 is located between the high-voltage component box 3 and the operating mechanism box 5, the operating mechanism box 5, the high-voltage component box 3 and the cable box 4 are all located above the cooling device 2, the cooling device 2 includes a mounting frame 6, a water storage tank 7, an air pump 8, an air duct 9 and an air spray head 10, one end of the air spray head 10 runs through the installation frame 6, and the other end of the air spray head 10 is connected to the air pump 8 through the air duct 9 , the air pump 8 is located on the right side of the water storage tank 7, the water storage tank 7 is provided with a heat dissipation pipe 11, one end of the heat dissipatio...

Embodiment 2

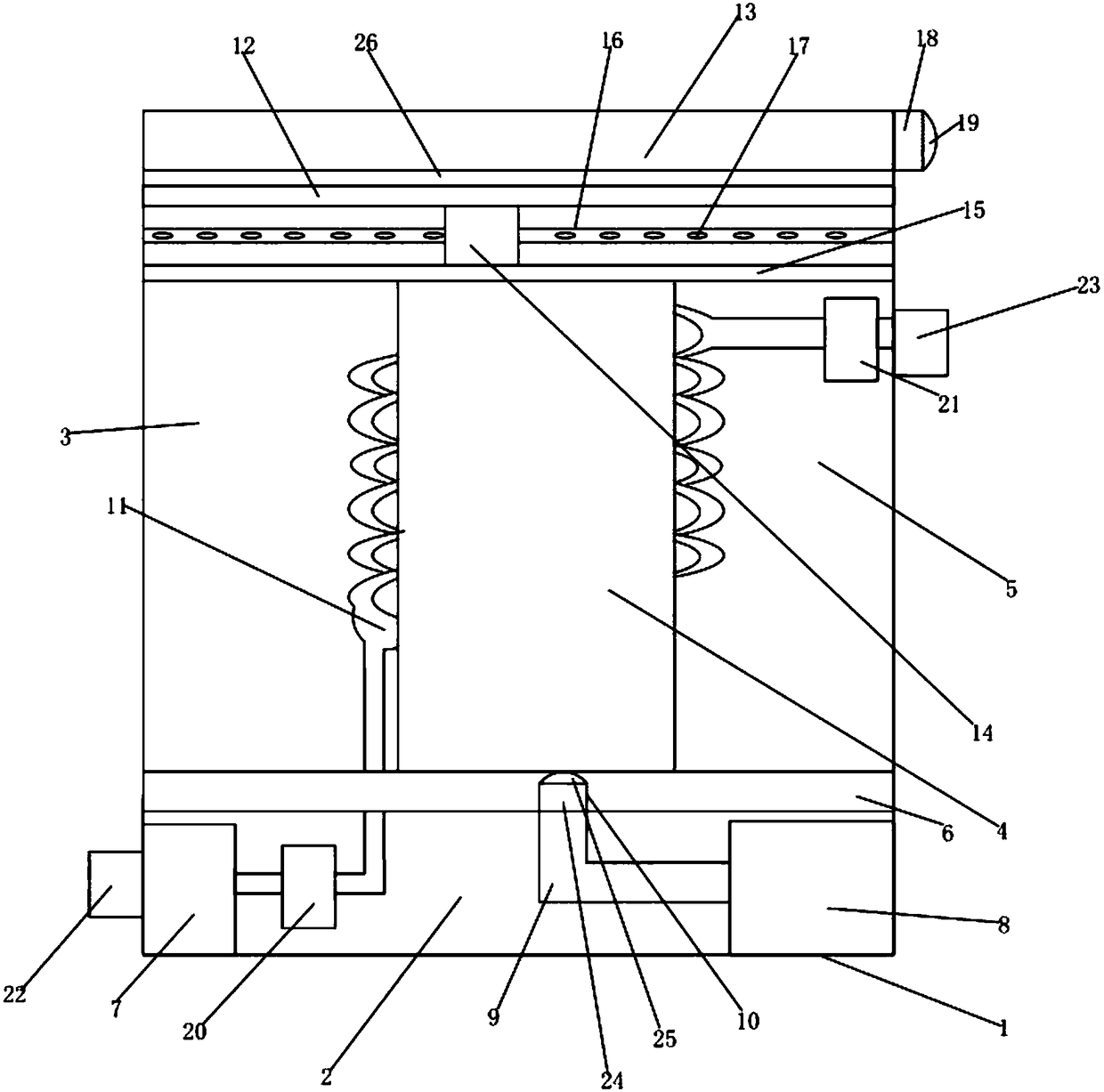

[0024] Refer to as figure 2 As shown, this embodiment is substantially the same as Embodiment 1, the difference is that a slide rail 26 is provided between the dust-proof plate 13 and the ventilation duct 12, and one end of the slide rail 26 slides with the dust-proof plate 13 The other end of the slide rail 26 is fixedly connected with the ventilation duct 12, so that the dustproof plate can be pushed to open manually, so that the dustproof plate slides along the slide rail to separate from the ventilation duct, which solves the problem that the top of the cabinet body in the prior art cannot To solve the problem and realize the purpose of smooth operation and low noise of the dust plate and the ventilation duct.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com