High-voltage DC stepped constant current closed loop precharge circuit

A pre-charging circuit, high-voltage DC technology, applied in battery circuit devices, secondary battery charging/discharging, circuits, etc., can solve the problems of upgrading, high cost, and low integration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, content, and advantages of the present invention clearer, the specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings and examples.

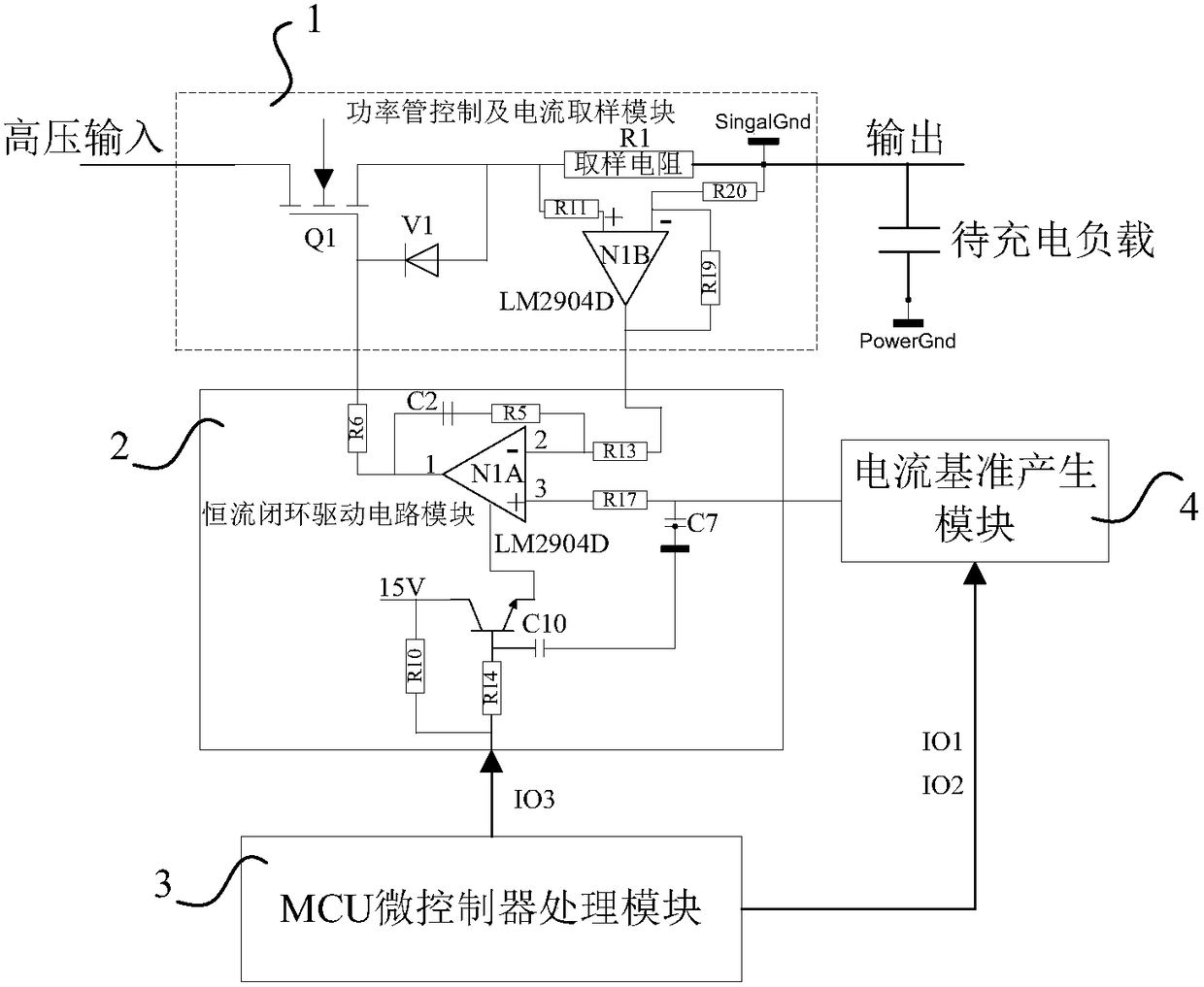

[0017] figure 1 Shown is the block diagram of the high-voltage direct current stepped constant current closed-loop pre-charging circuit of the present invention, as figure 1 As shown, the power tube control and current sampling module 1, the constant current closed-loop drive circuit module 2, the MCU micro-control processing module 3 and the current reference generation module 4.

[0018] Such as figure 1 As shown, the power tube control and current sampling module 1 mainly completes the grid control of the power tube and the sampling of the charging current. Power tube control and current sampling module 1 includes power tube body Q1, Zener diode V1, filter capacitor C1, sampling resistor R1 and operational amplifier ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com