Extrusion mould

A technology of extrusion dies and empty knives, which is applied in the direction of metal extrusion dies, etc., can solve the problems of high extrusion force, speed cannot be increased, and die scrapping of the splitter die, so as to increase extrusion speed, reduce movement, and service life long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

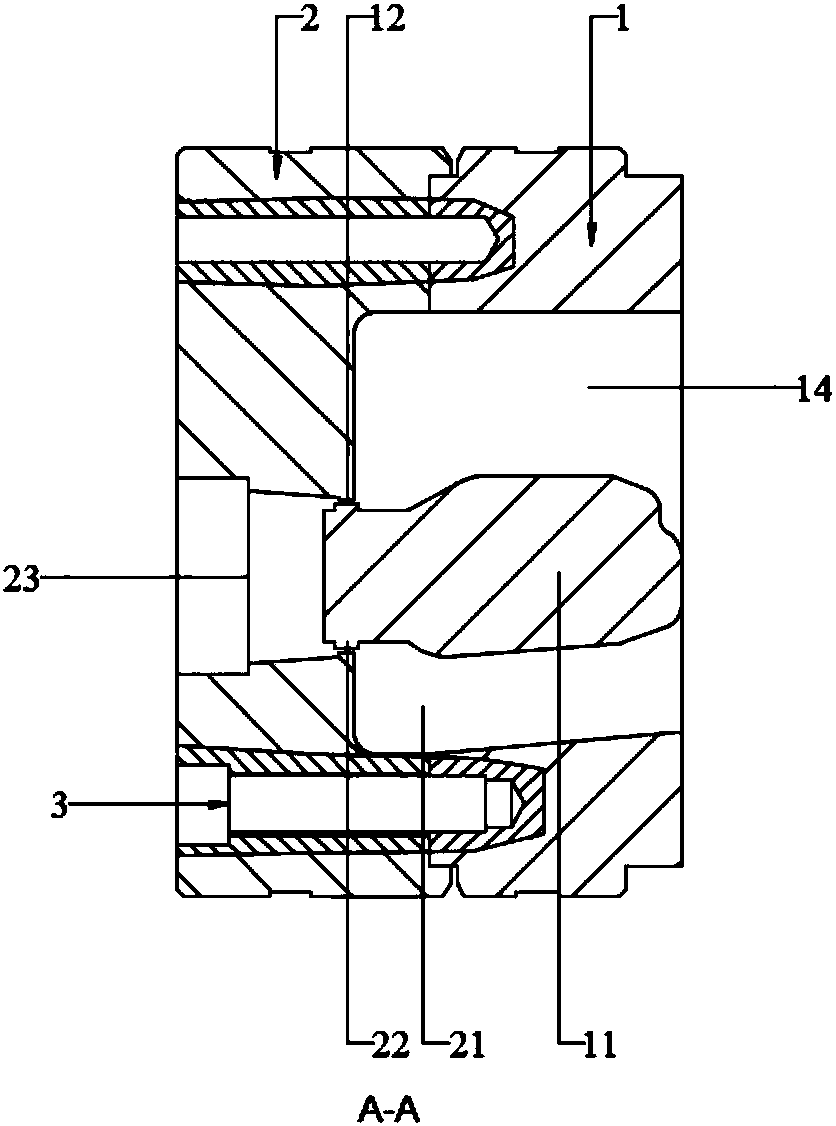

[0047] Please refer to Figure 1 to Figure 8 Shown, embodiment one of the present invention is:

[0048] An extrusion die, comprising an upper die 1 and a lower die 2 connected to each other;

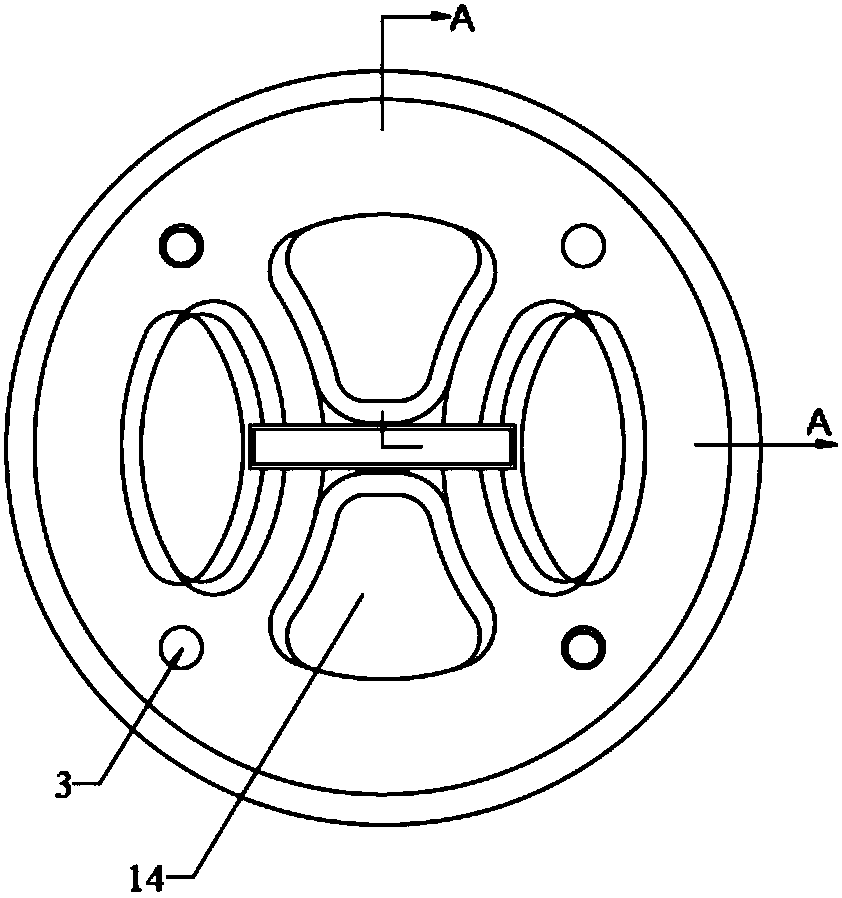

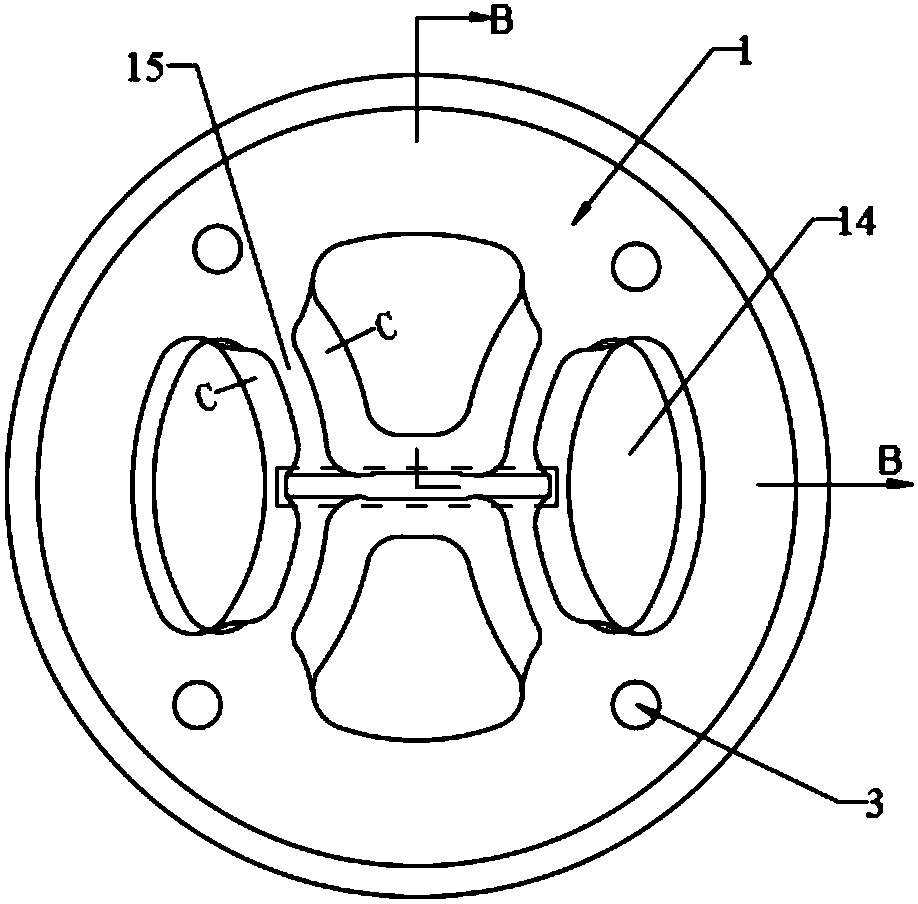

[0049] The middle part of the upper die 1 is provided with a tongue core 11, and the tongue core 11 is arranged from the feed end of the upper die 1 to the discharge end of the upper die 1, and extends out of the discharge end of the upper die 1 to form a protrusion 111, the protrusion 111 is provided with a first working belt 12, and the side of the first working belt 12 close to the discharge end of the upper mold 1 is provided with a lower empty knife 13;

[0050] There are four distribution holes 14 running through the upper die evenly distributed on the feed end circumference surface of the upper die 1, and a splitter bridge 15 is arranged between the split holes 14, and the split bridge 15 is formed from the feed end of the upper die 1. The section from the inlet side to the out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com