Breaking method and breaking device of brittle material substrate

A technology of brittle material substrate and disconnecting device, which is applied to fine working devices, stone processing equipment, electrical components, etc., can solve the problems of easy warping of substrates, complex structure, and difficult alignment of the focus of surveillance cameras.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

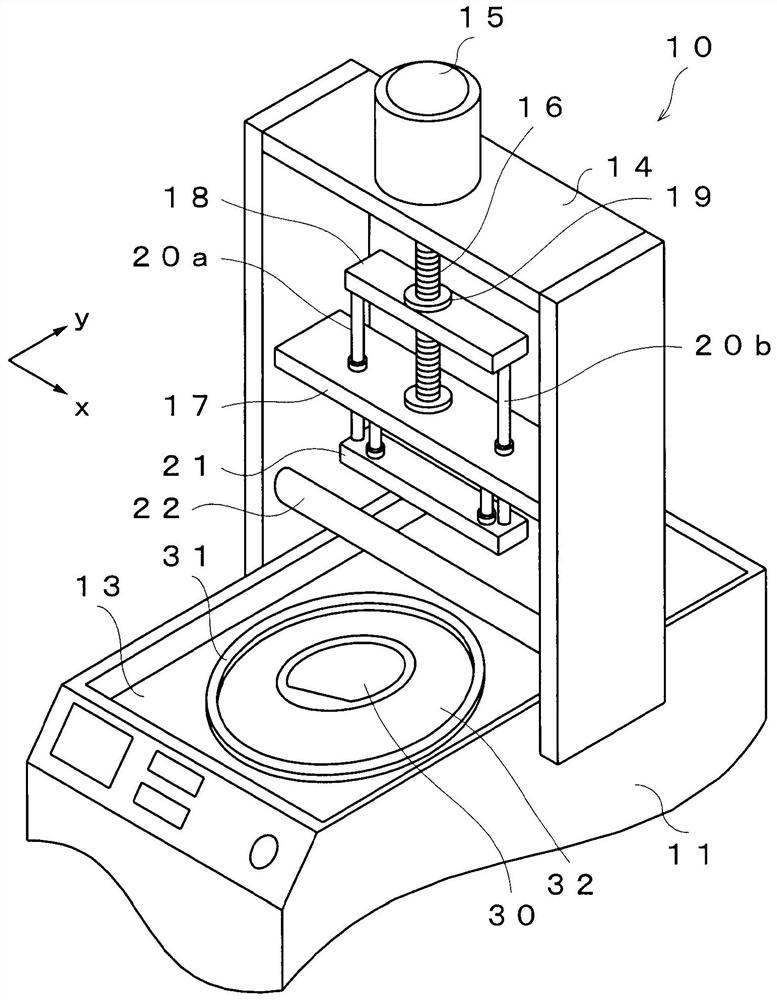

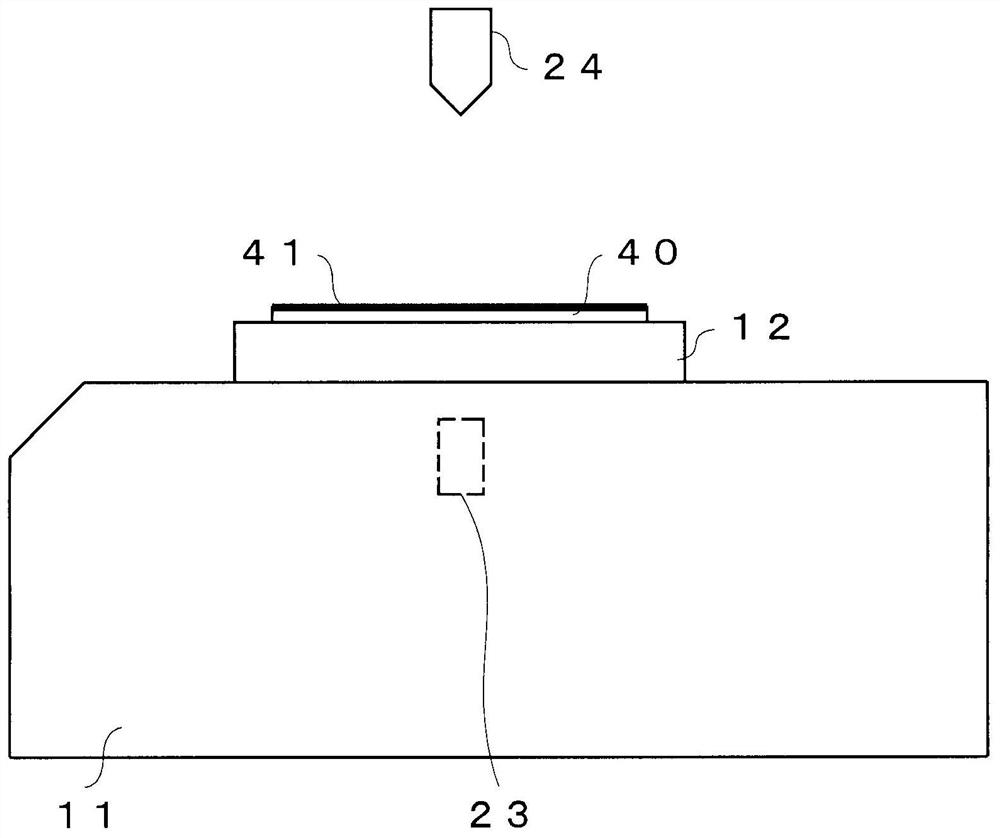

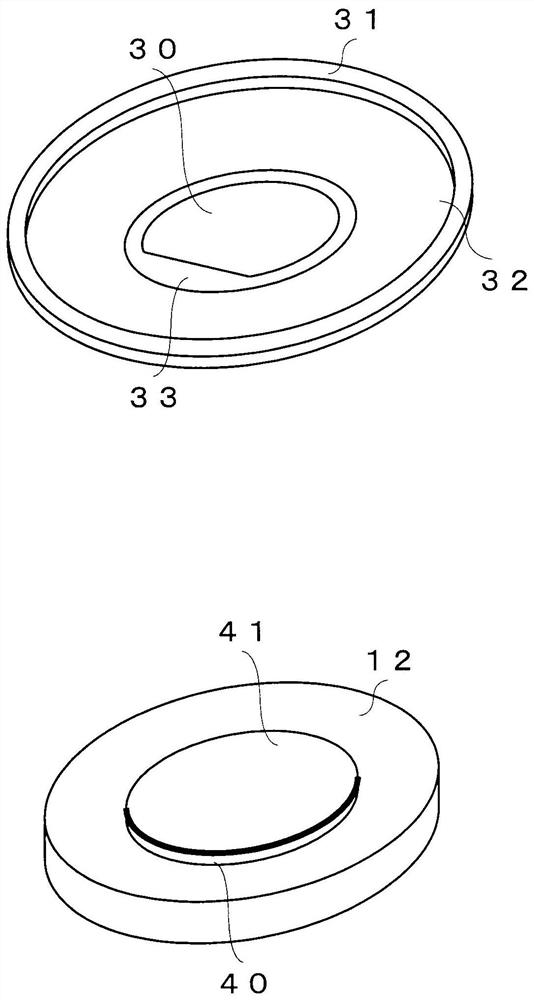

[0020] Next, an outline of the breaking device 10 used for breaking the brittle material substrate of this embodiment will be described. figure 1 It is a schematic perspective view of the breaking device according to the embodiment of the present invention, figure 2 It is a schematic side view of the disconnecting device. The breaking device 10 has a transparent glass table 12 on a base 11 that can move in the positive or negative direction of the y-axis. Below the glass table 12, the Y-axis movement mechanism 13 which moves the glass table 12 in the y-axis direction along this surface, and rotates along this surface is provided. A U-shaped frame-shaped fixing member 14 is provided on the upper side of the glass table 12 , and a servo motor 15 is held on the upper side of the frame-shaped fixing member 14 . The rotary shaft of the servo motor 15 is directly connected to the ball screw 16 , and the lower end of the ball screw 16 is rotatably supported by the horizontal fixin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com